Device for detecting after-operation line level parameters of tamping car

A technology of horizontal parameters and tamping vehicles, which is applied to roads, measuring instruments, track superstructures, etc., can solve the problems of high labor intensity and low efficiency, reduce labor intensity, improve detection efficiency, and save manual inspection links Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

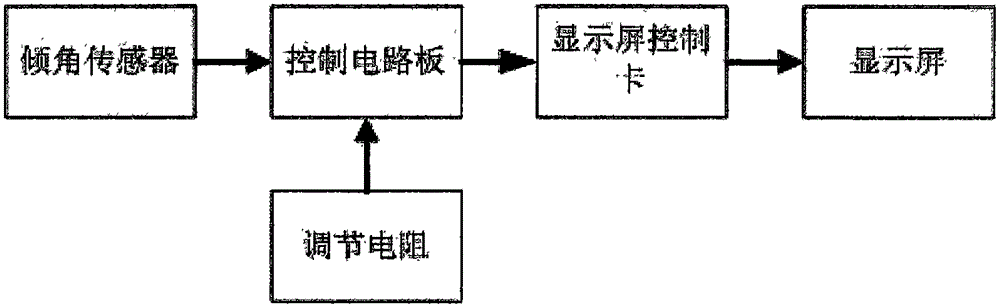

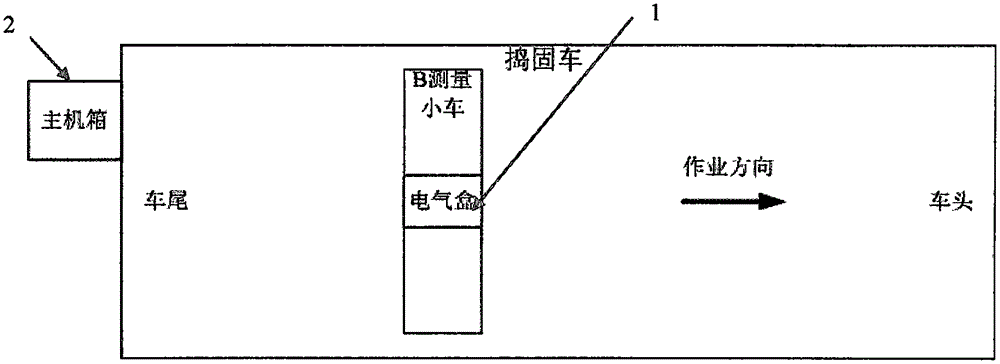

[0010] Such as figure 2 As shown, the detection device of the present invention includes a main box and an electrical box. Its specific composition and function are as follows:

[0011] (1) Main chassis

[0012] Including control circuit board, display screen, display control card and adjusting resistor. It mainly realizes collecting the data of horizontal parameters and adjusting resistance data, analyzing and processing the data, and displaying the measurement results in real time.

[0013] (2) Electrical box

[0014] Mainly includes the inclination sensor. It mainly collects horizontal parameters of the line after the tamping vehicle operation.

[0015] Concrete work process of the present invention is as follows:

[0016] After the inclination sensor in the electrical box detects the horizontal parameters of the line, the data is sent to the control circuit board in the main box. The control circuit board calculates the measured data and the fixed error output by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com