Battery bag overturning test device

A flipping test, battery pack technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems that affect the accuracy of detection data, personal safety cannot be guaranteed, etc., to save manual inspection and optimize product design , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

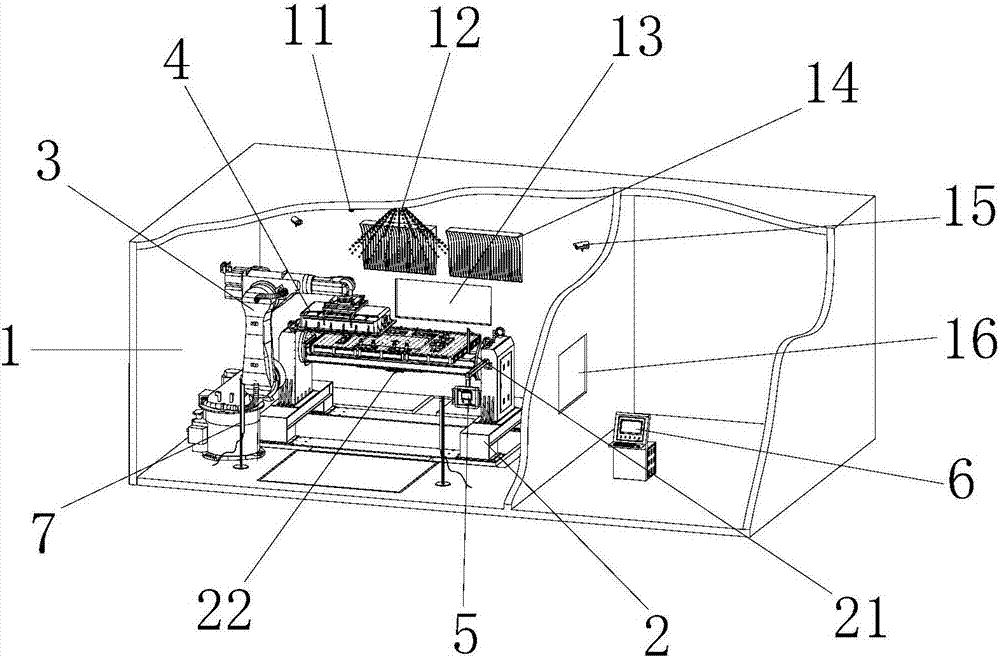

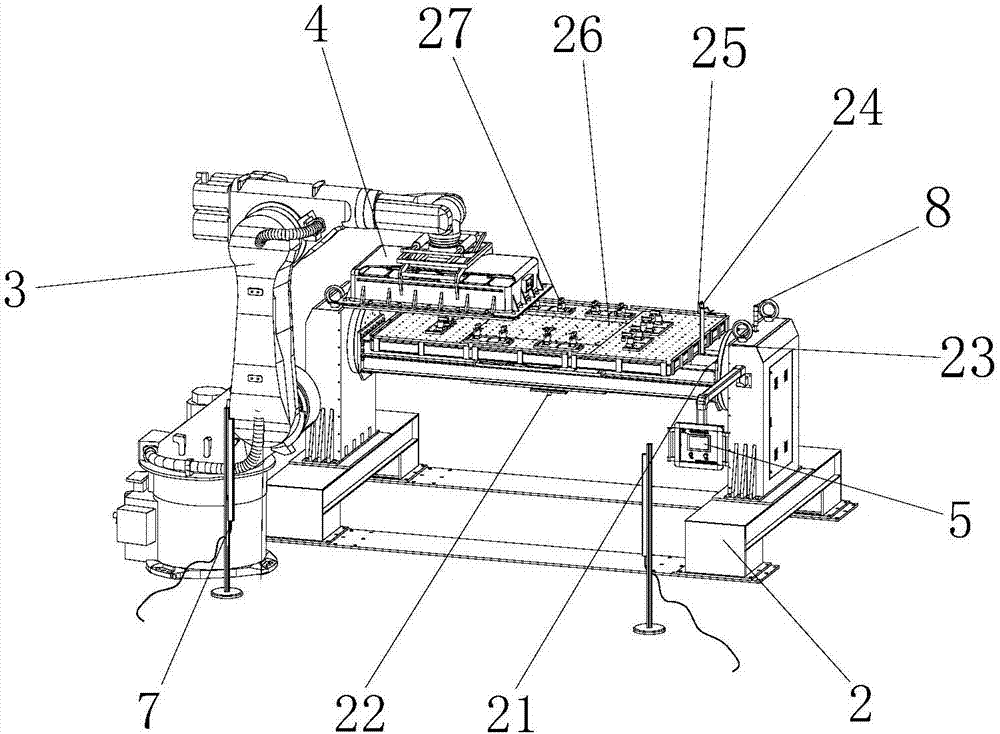

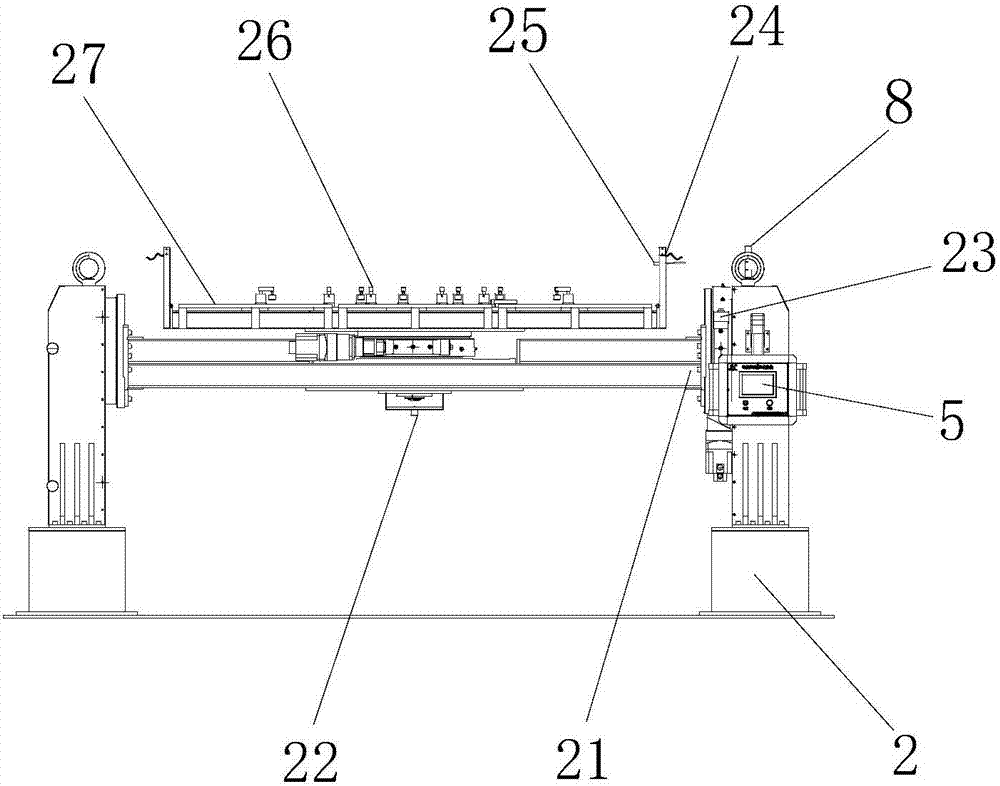

[0021] See Figure 1 to Figure 4 As shown: the present invention includes a protective wall 1, a flip test bench 2, a loading and unloading robot arm 3, a battery pack 4, a PLC touch controller 5, a PC remote monitor 6, and a safety grating 7, and a smoke alarm is provided on the protective wall 1 11. Spray fire extinguishing device 12, pressure relief port 13, smoke exhaust kitchen 14, video monitor 15, monitoring window 16, three-color alarm light 8, infrared temperature sensor 24, infrared object sensor 25, X Axis beam rotation assembly 21 , Y-axis platform rotation assembly 22 , installation platform 26 , and tab pneumatic clamp 27 is arranged on installation platform 26 .

[0022] The loading and unloading robotic arm 3 detects the position of the object through the safety grating 7 and the infrared object sensor 25 .

[0023] The X-axis beam rotation assembly 21 and the Y-axis platform rotation assembly 22 are provided with a rotation power device 23 .

[0024] The rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com