Honeycomb buffer shockproof, moisture-proof and flame-retardant express bag or packaging bag and bag making production line thereof

A cushioning shockproof, packaging bag technology, applied in the field of express bags or packaging bags, can solve the problems of environmental pollution of express bags, and achieve the effects of good moisture resistance, easy degradation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

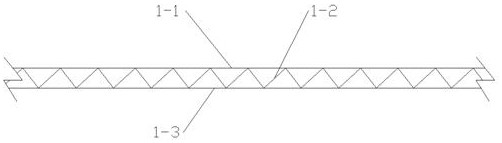

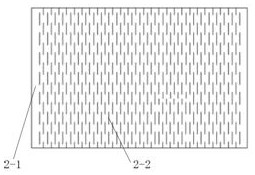

[0018] Such as Figure 1-4 As shown, a honeycomb cushioning shockproof, moisture-proof, flame-retardant courier bag or packaging bag, the courier bag or packaging bag is formed by folding and bonding composite paper 1, and the composite paper 1 includes a middle layer 1-2 and an upper surface layer 1-1 1. The lower surface layer 1-3, the upper surface layer 1-1 and the lower surface layer 1-3 are kraft paper, the middle layer 1-2 is corrugated by stretching honeycomb paper, and the three layers are connected by glue; The honeycomb paper is a fire-resistant paper 2-1 with several longitudinal cuts 2-2 evenly distributed on it, the longitudinal cuts 2-2 are distributed in a matrix, and between two adjacent rows of longitudinal cuts 2-2 Misalignment, 1 / 2 length of vertical cuts 2-2 between two adjacent rows of vertical cuts 2-2; the honeycomb paper is stretched, the longitudinal cuts 2-2 are torn apart, two adjacent cuts The flame-retardant paper 2-1 is twisted between the marks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com