Processing method for laminated paper bag

A processing method and film-covering technology, which is applied to bags, sacks, papermaking, etc., can solve the problems that the stock film does not meet the surface tension required for bonding, short timeliness, and low surface dyne value strength, etc., and achieve product quality Stable and reliable, long-lasting, long-lasting and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The processing method of a film-coated paper bag of the present invention comprises the following steps (1) paper printing: printing the design pattern on the paper to make a printed matter; (2) post-printing film coating: covering the surface of the printed matter with a layer of transparent plastic film Made of laminated printed matter; (3) Die-cutting processing: Die-cutting and indentation processing of laminated printed matter; (4) Plasma treatment process: Perform plasma treatment on the area to be bonded of the laminated printed matter after die-cutting processing; (5) Box paste process: apply adhesive on the area to be bonded after plasma treatment, join the area to be bonded, and make a coated paper bag after curing the adhesive.

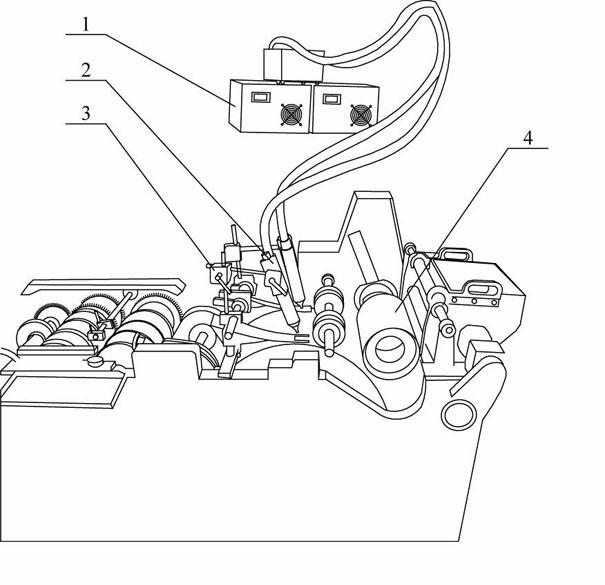

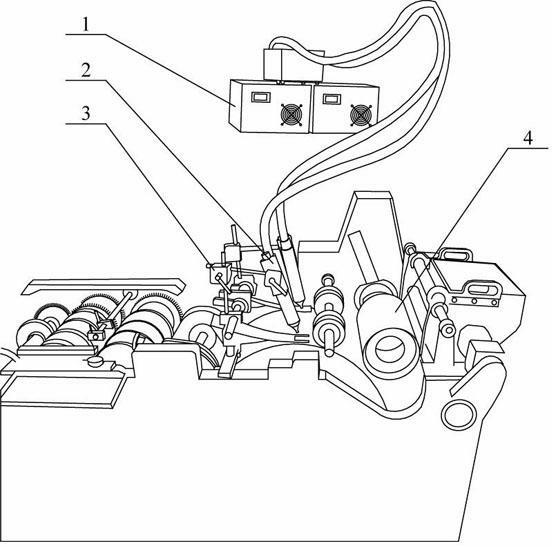

[0029] Plasma treatment is performed on the area to be bonded on the surface of the laminated printed matter by a plasma treatment device. The plasma processing device is composed of a host 1 for generating high-voltage and high-freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com