Punching device for formed portable paper bag

A punching device and handbag technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of asymmetry, affect the overall appearance of the paper bag, etc., and achieve the effect of small hole position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

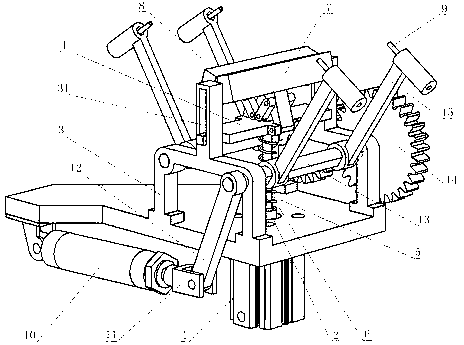

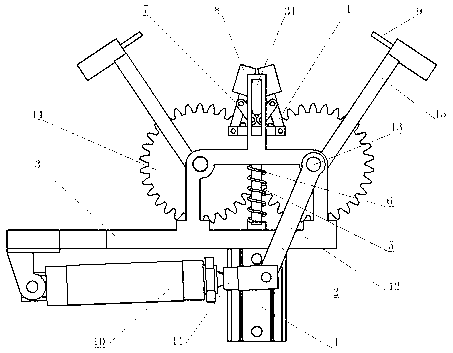

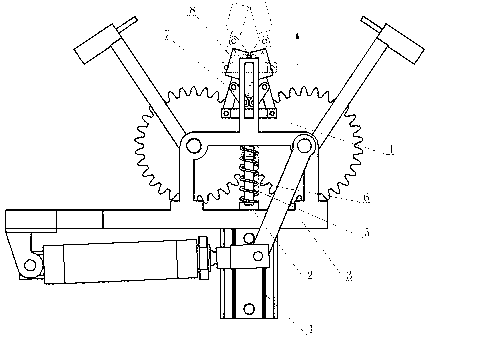

[0022] Such as figure 1 , figure 2 A handbag punching device shown includes a punching head (9), a receiving plate (8), a stroke cylinder (1), a swing tail cylinder (10), and a pair of ear joints (11), and is characterized in that: The stroke cylinder (1) is connected with the frame (3), and the frame (3) has a long slot (31) and two symmetrical round holes, and the piston rod (2) of the stroke cylinder (1) is connected with the top The rod (5) is connected, the ejector rod (5) is set in the middle hole of the stroke plate (4), the head of the ejector rod (5) is hinged with the connecting rod (7), and the connecting rod (7) is another One end is hinged to the middle of the receiving plate (8), and the bottom end of the receiving plate (8) is hinged to the stroke plate (4); the two ends of the stroke plate (4) are inserted into the long slot (31) of the frame (3). ), there is a spring (6) between the stroke plate (4) and the piston rod (2), and two swing shafts (13) are set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com