Accurate machining method for large-diameter porous workpieces

A processing method and large-diameter technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as difficult to complete high-quality and precise processing of deformable porous parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

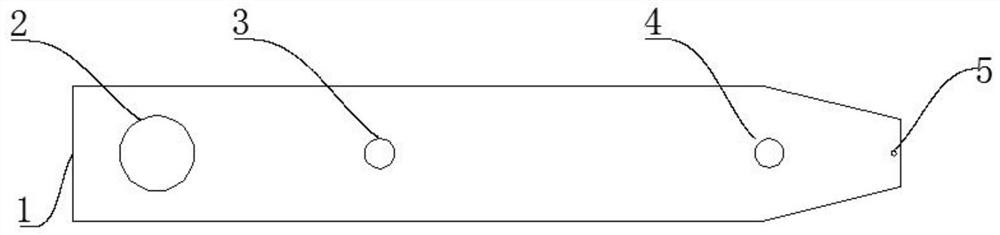

[0024] Example 1, such as figure 1 As shown, this embodiment provides a tooling for processing large-diameter porous workpieces, including a strip-shaped body 1, and the body 1 is sequentially processed with pin hole 1, pin hole 2, pin hole 3, and pin hole 4 along the center line. Pin hole four 5, and one end that body 1 is processed with pin hole four 5 is trapezoid. The diameters of pin hole one 2 to pin hole four 5 decrease successively.

Embodiment 2

[0025] Embodiment 2, a method for precisely machining large-diameter porous workpieces, comprising the following steps:

[0026] A. Design and process tooling for processing large-diameter porous workpieces, which will be referred to as tooling in the future. There are pin holes 1 and 4 with a center distance equal to the radius of the pin hole indexing circle on the workpiece to be processed. Pin holes 1 and 2 Also be provided with pin hole two 3 and pin hole three 4 between pin hole four 5, the circle center of pin hole two 3 and pin hole three 4 is positioned at the connecting line of pin hole one 2 and pin hole four 5 circle centers;

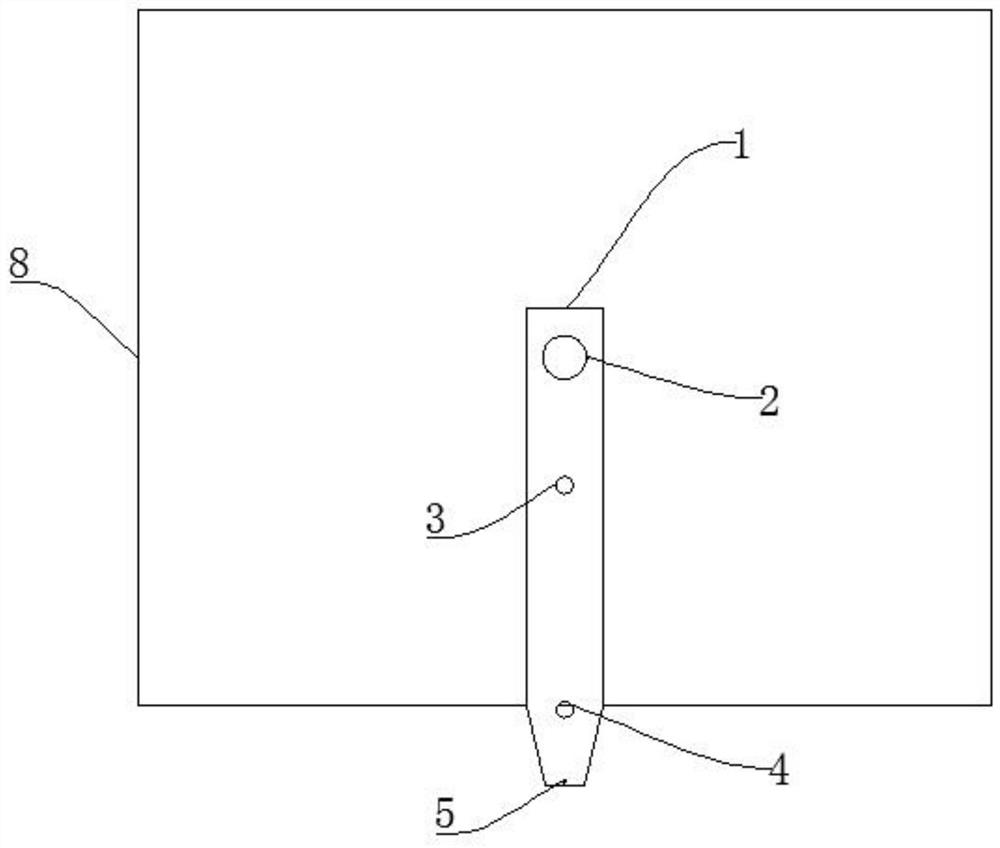

[0027] B. First use the pressure plate to position and fix the tooling on the rotary table 8 of the machining center, such as figure 2 As shown, adjust to make the pin hole 1 concentric with the rotary table 8. Specifically, fix the dial indicator at the front end of the main shaft, extend the main shaft so that the pointer of the dial indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com