Vertical type food material baking device and method

A roasting device and roasting method technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of undercooking, easy dripping of ingredients and fats to the heat source, and generation of oily smoke, so as to avoid burns , Reduce labor costs, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

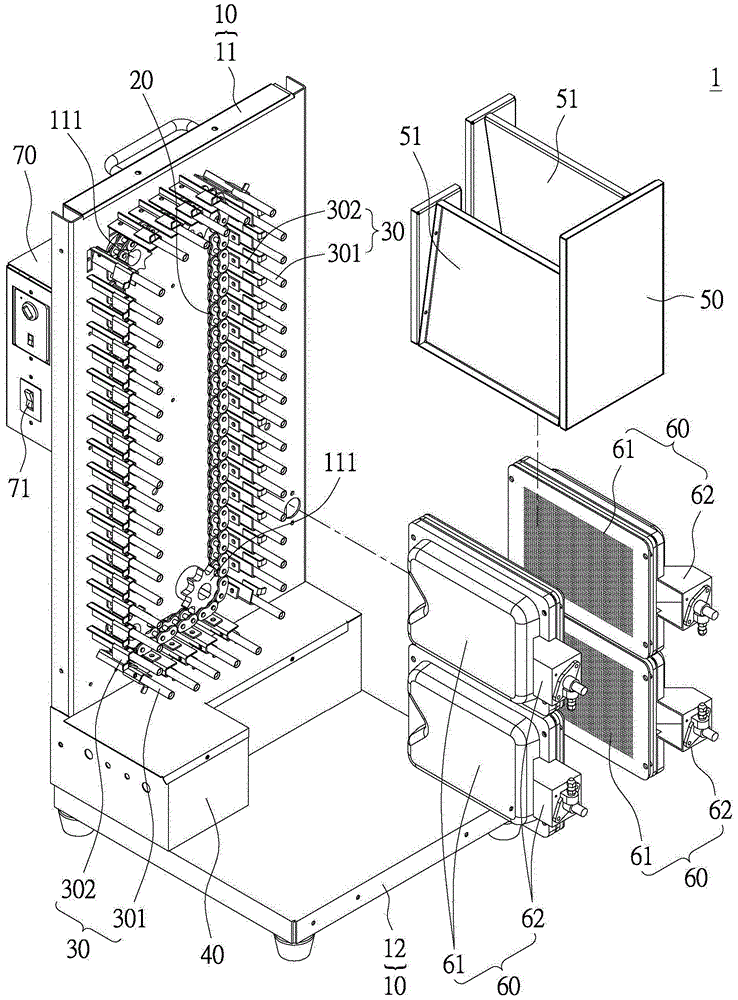

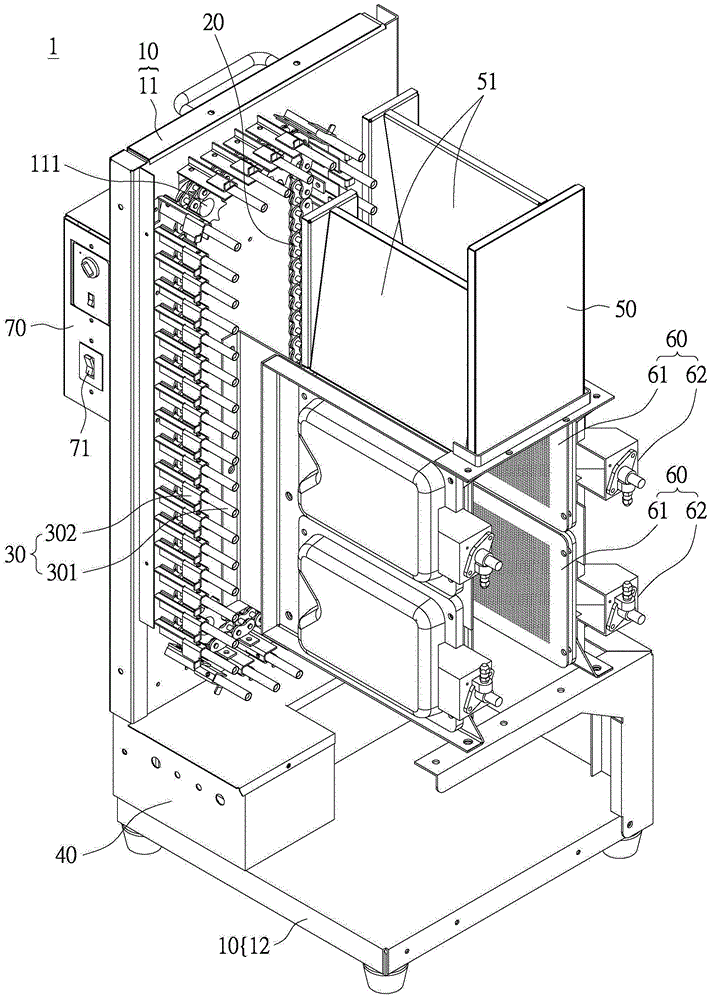

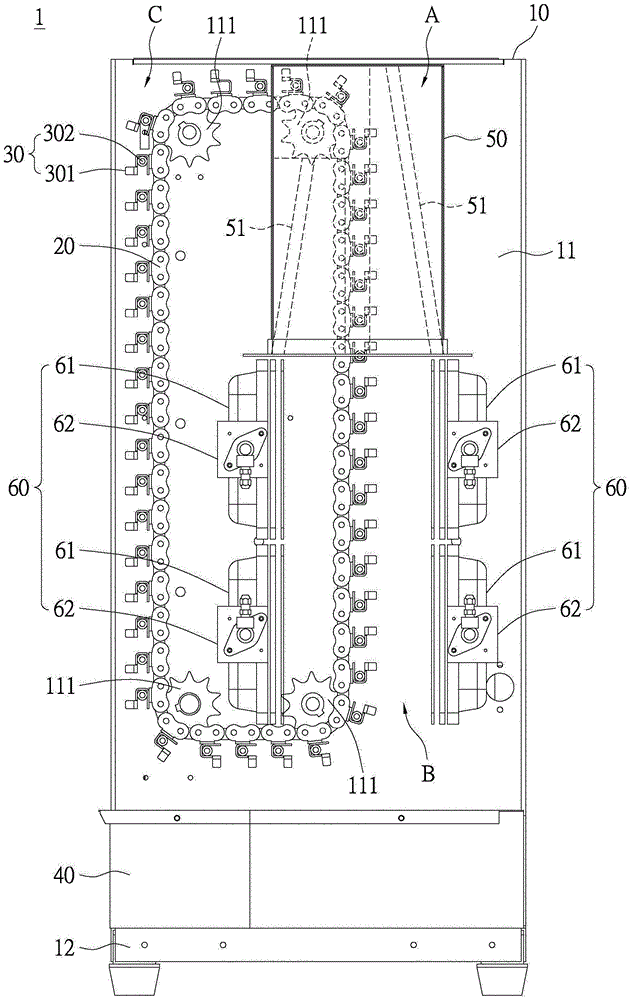

[0067] Please also refer to Figure 1 to Figure 3 , which is an exploded view and a schematic assembly diagram of the upright food roasting device of the present invention. Such as figure 1 and figure 2As shown, the upright food roasting device 1 includes a body 10 , a transmission chain belt 20 , a plurality of loading units 30 , a driving module 40 , a heat insulation baking cover 50 , a heating module 60 and a control module 70 . The body 10 includes an upright platform 11 and a base 12 , and the upright platform 11 is disposed on the base 12 perpendicular to the horizontal plane. The transmission chain belt 20 is a closed-loop chain belt, which is arranged around a plurality of driving wheels 111 on the upright carrier 10 . At least one driving wheel 111 is mechanically connected to the driving module 40 so as to be driven by the driving module 40 to rotate, thereby driving the transmission chain belt 20 to rotate. Wherein, the transmission chain belt 20 in the figure...

no. 2 example

[0076] Please also refer to Figure 4 to Figure 5 , which is a schematic view of the second embodiment of the vertical food roasting device of the present invention. As shown in the figure, the upright food roasting device 2 includes a body 10, a transmission chain belt 20, a plurality of loading units 30, a driving module 40, a heat insulation baking cover 50, a heating module 60, and a control module. 70 and a material returning module 80. Among them, with regard to the detailed components of the main body 10, the transmission chain belt 20, the loading unit 30, the driving module 40, the heat-insulating baking cover 50, the heating module 60 and the control module 70 and their related connection and action relationships, they are similar to those of the foregoing embodiments. Similar, so I won't repeat them here. The difference between this embodiment and the foregoing embodiments is that the heating module 60 may also include a cover 63, and the cover 63 includes two set...

no. 3 example

[0085] Such as Figure 7 As shown, it is a schematic flow chart of the food baking method of the present invention. As shown in the figure, the food baking method may include the following steps:

[0086] S1: Provide an upright platform perpendicular to the horizontal plane, and the upright platform is provided with a transmission chain belt, and a plurality of material placement units are arranged at intervals on the transmission chain belt, and a plurality of food inserts are respectively arranged on each material placement unit, and One section of the transmission chain belt is a baking zone with a heat-insulating baking cover on the top, and a direct heating zone with a heating module on both sides below the baking zone. For example, the upright carrier can be set on a base, and the transmission chain belt can be a closed endless chain belt, which can be sleeved on a plurality of driving wheels on the upright carrier, and at least one driving wheel mechanism It is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com