Multifunctional processing device for printed circuit board

A technology for printed circuit boards and processing devices, which is applied in the field of processing devices for printed circuit boards. It can solve the problems of inconvenient magnifying lens wiping, inconvenient application of solder paste, and lack of air cooling and cooling functions, so as to increase convenience and improve Efficiency, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

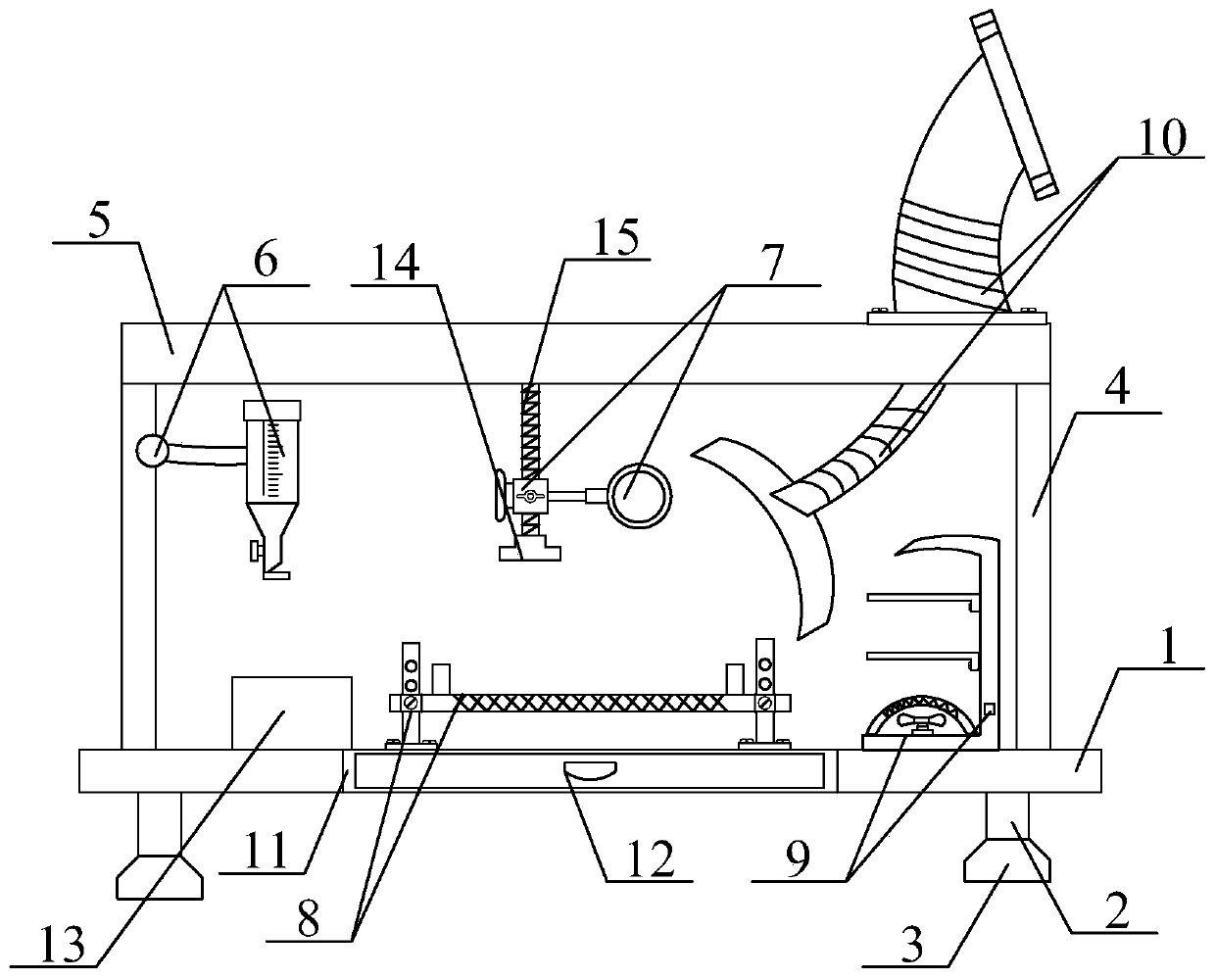

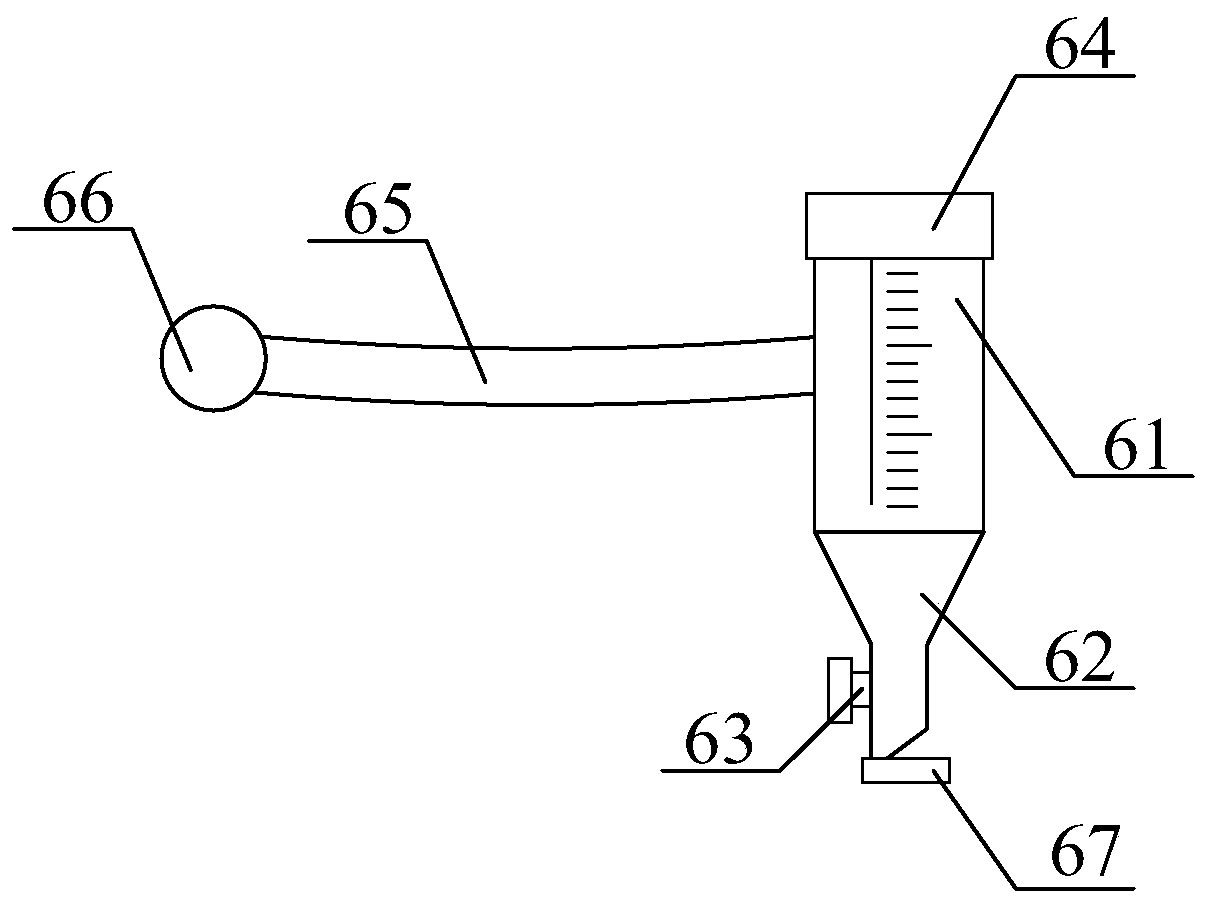

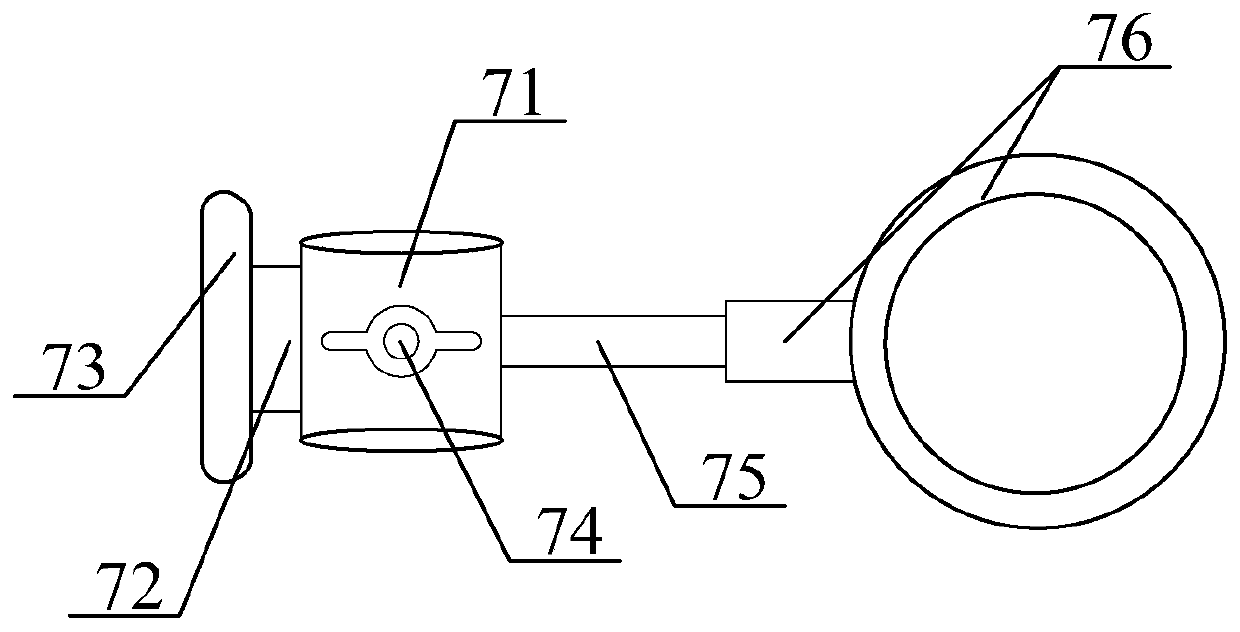

[0040] as attached figure 1 to attach figure 2 As shown, the present invention provides a multifunctional printed circuit board processing device, including a support base plate 1, a support screw lever 2, a rubber plate 3, a support column 4, a protective top plate 5, an adjustable solder paste storage bottle structure 6, Easy to wipe adjustable magnifying glass structure 7, adjustable circuit board processing support mesh structure 8, layered cooling shelf structure 9, smoke absorption connection tube structure for easy connection 10, drawer groove 11, drawer plate 12, welding seat 13. Limiting blocking cap 14 and screw column 15, the support screw levers 2 are respectively screwed to the four corners of the lower surface of the support base plate 1; the rubber disc 3 is screwed to the lower end of the support screw lever 2; The lower ends of the support columns 4 are respectively bolted to the four corners of the upper surface of the support base plate 1, and the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com