High-performance cotton thread moistening device for textile production

A high-performance, cotton thread technology, applied in the processing of textile materials equipment configuration, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of low efficiency and poor effect of cotton threads, and achieve good thread effect, high efficiency, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

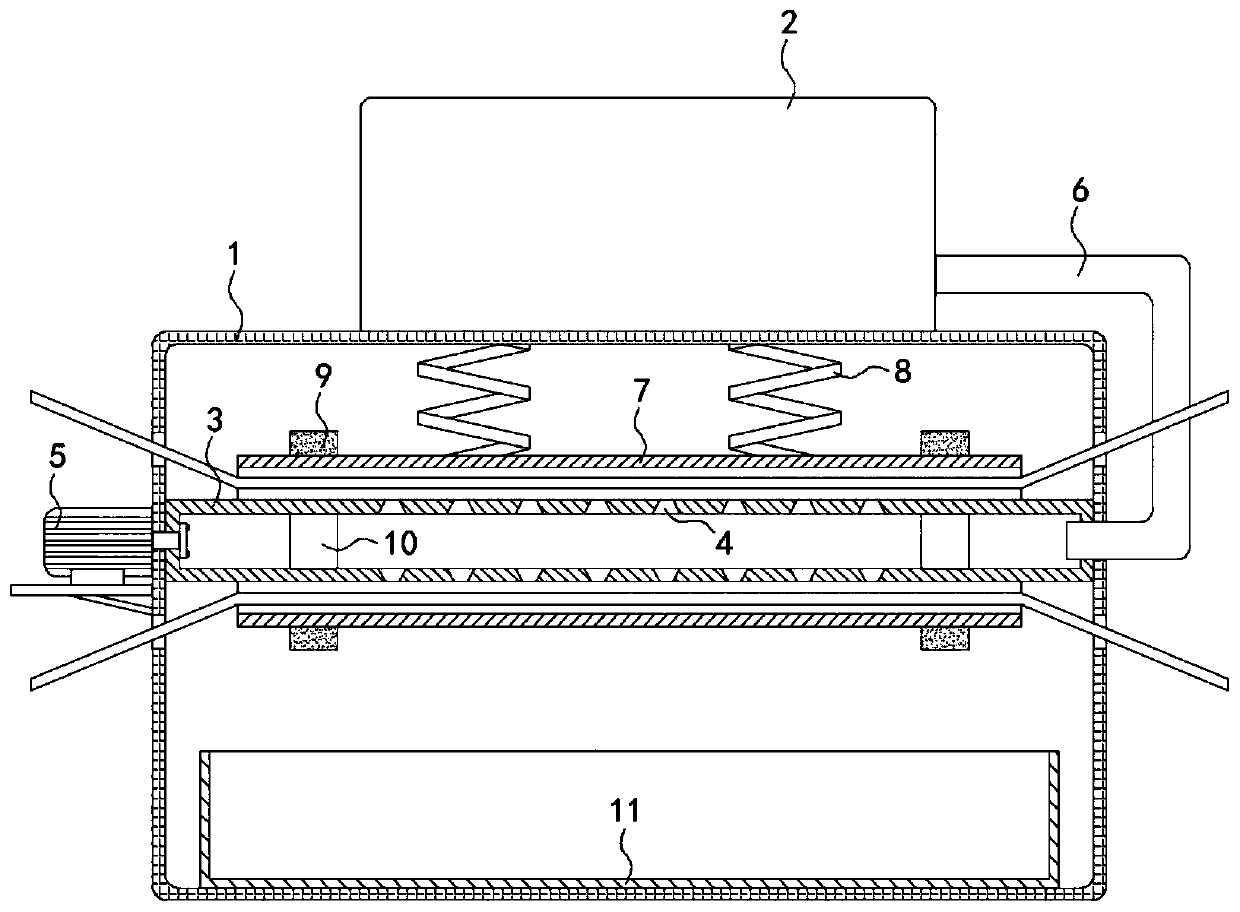

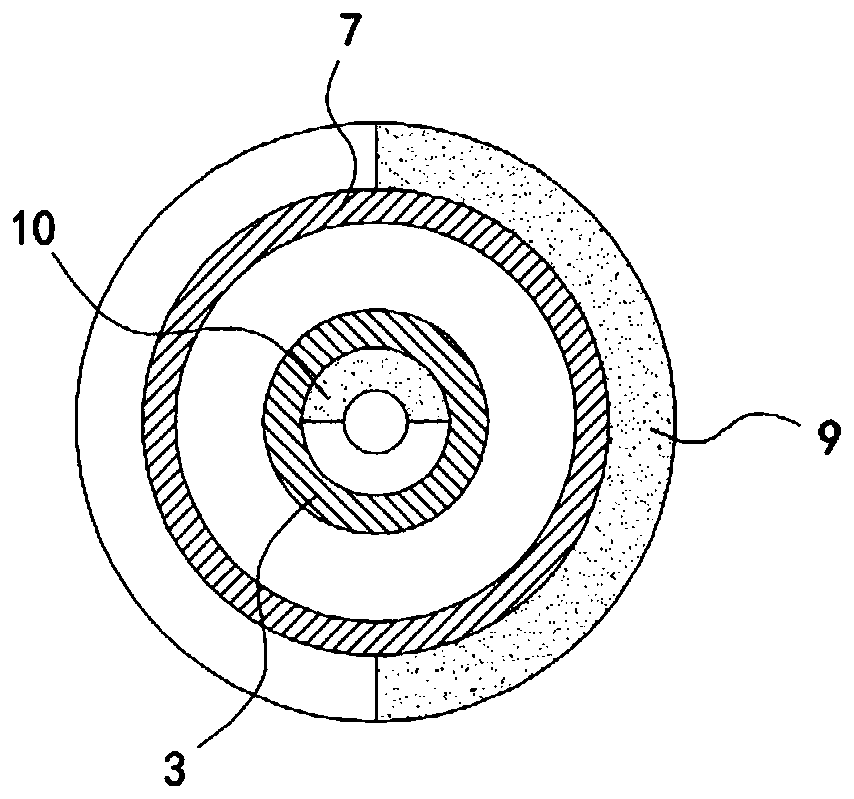

[0020] Such as Figure 1-2 As shown, a high-performance cotton thread finishing device for textile production includes a box body 1, an oil storage tank 2 is fixedly connected to the upper end of the box body 1, and a horizontally arranged rotating inner tube 3 is rotatably connected to the inner side wall of the box body 1. The side wall of the rotating inner tube 3 is provided with a plurality of oil outlet holes 4 that are arranged through. The pore diameter of 4 gradually decreases from the inside to the outside, which can accelerate the outflow of silicone oil.

[0021] In this embodiment, a motor 5 is fixedly installed on the side wall of the box body 1, the output shaft of the motor 5 runs through the box body 1 and is coaxially fixedly connected with the rotating inner tube 3, and an oil outlet pipe is fixedly connected to the side wall of the oil storage tank 2 6. The lower end of the oil outlet pipe 6 runs through the box body 1 and the rotating inner pipe 3 in turn...

Embodiment 2

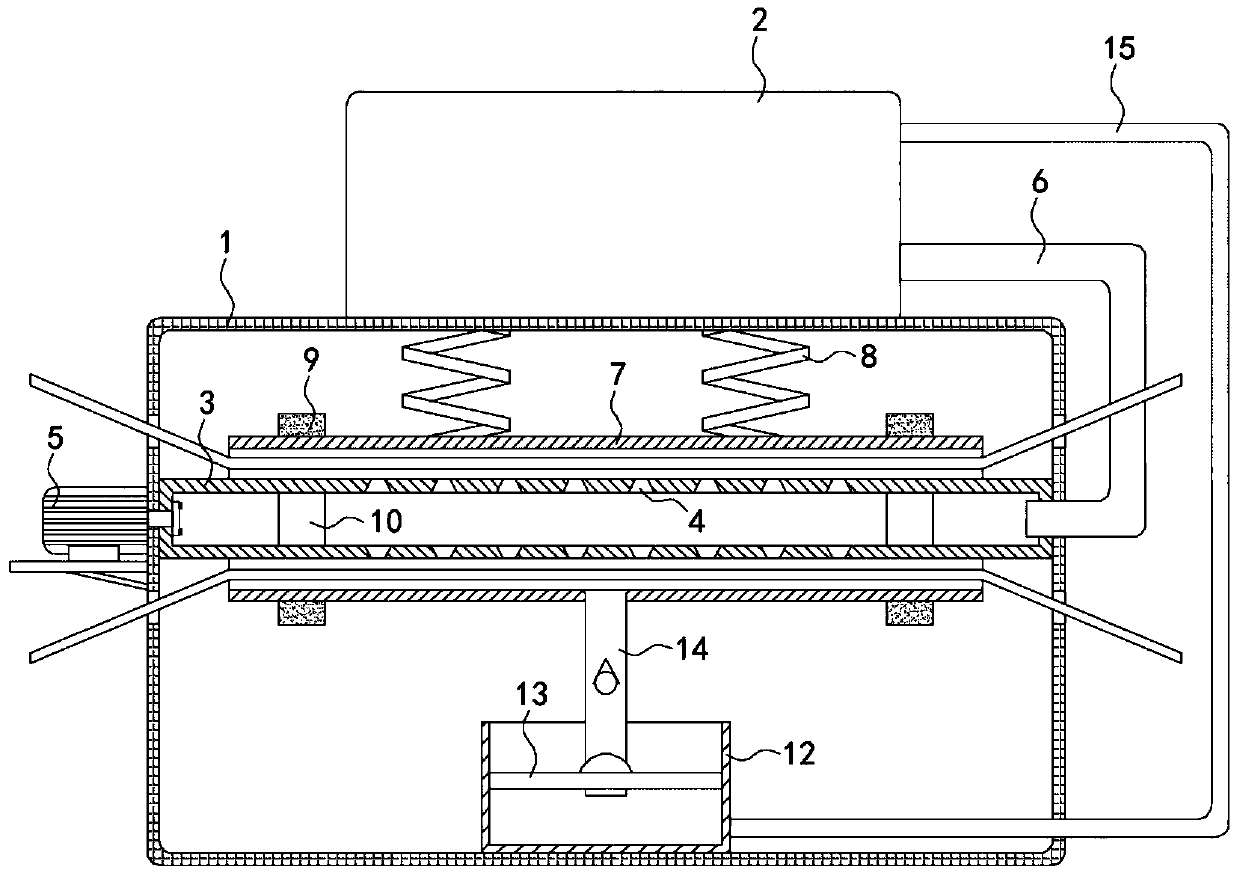

[0026] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the inner bottom surface of the box body 1 is fixedly connected with an oil return tank 12, the upper end of the oil return tank 12 is opened, and the inner side wall of the oil return tank 12 is sealed and slidably connected with a piston plate. 13. The piston plate 13 is provided with a one-way air outlet hole set through the piston plate 13, and the piston plate 13 is connected with a one-way recovery pipe 14. It should be noted that the one-way recovery pipe 14 is fixedly sleeved with a sealing rubber The outer ring of the sealing rubber ring is fixedly connected with the piston plate 13, and the sealing rubber ring can be deformed, so that the one-way recovery pipe 14 can move freely in the piston plate 13, and the connection between the one-way recovery pipe 14 and the piston plate 13 is guaranteed. The upper end of the one-way recovery pipe 14 runs through the movable outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com