Organic silicone coated adhesive and preparation method and application thereof

A technology of coating glue and silicone, applied in the direction of adhesives, etc., can solve the problems of slow curing speed, poor storage stability, easy yellowing, etc., and achieve the effect of fast curing speed, stable performance and good resistance to yellowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

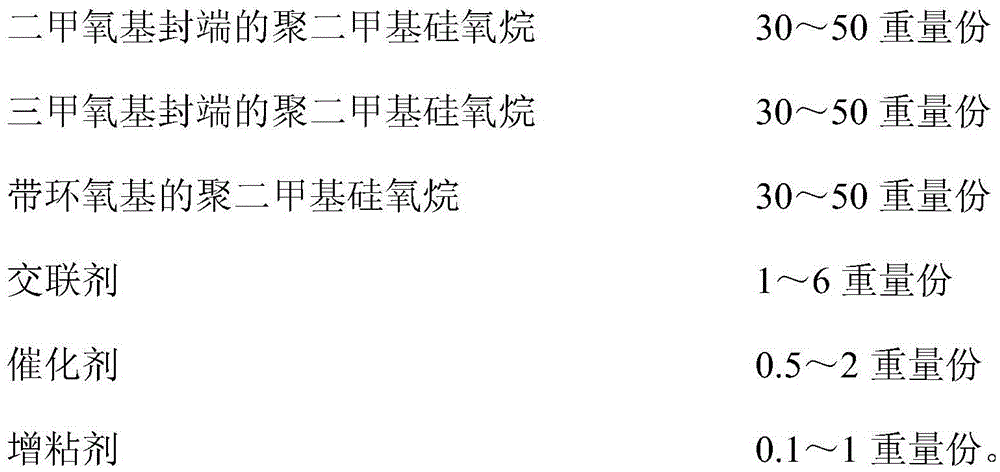

[0046] In this embodiment, the silicone coating glue contains the following components by weight:

[0047]

[0048] Its preparation method specifically comprises the following steps:

[0049] (1) Add dimethoxy-terminated polydimethylsiloxane, trimethoxy-terminated polydimethylsiloxane, and epoxy-grouped polydimethylsiloxane to a dynamic mixer, Vacuumize until the vacuum degree is -0.09MPa, stir for 10min;

[0050] (2) Add crosslinking agent (methyl orthosilicate), catalyst (tetraisopropyl titanate) and tackifier (silane coupling agent with epoxy group) successively in the mixture obtained in step (1), After each substance is added, vacuumize to -0.09MPa, and stir for 10 minutes until the last substance is added and mixed evenly, then discharged, packaged, and silicone coating rubber is obtained.

Embodiment 2

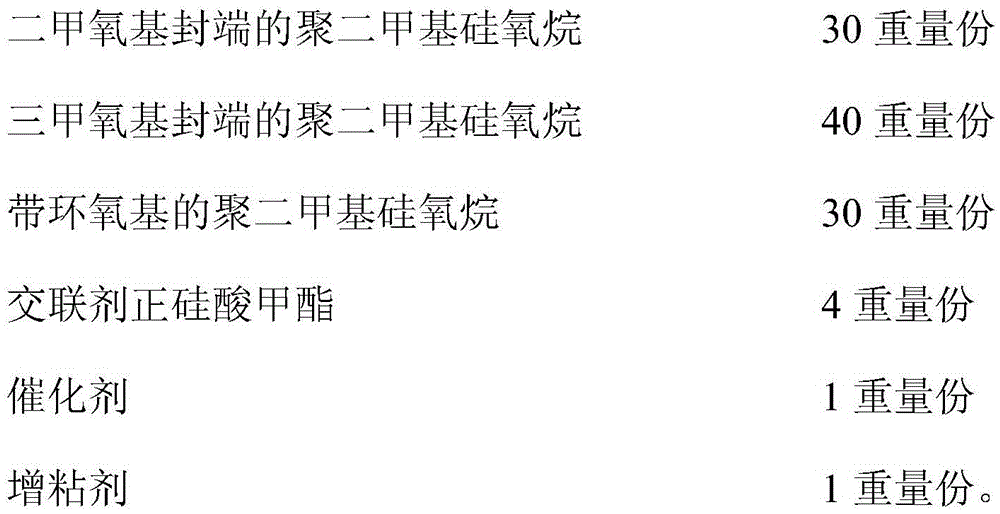

[0052] In this embodiment, the silicone coating glue contains the following components by weight:

[0053]

[0054] Its preparation method specifically comprises the following steps:

[0055] (1) Add dimethoxy-terminated polydimethylsiloxane, trimethoxy-terminated polydimethylsiloxane, and epoxy-grouped polydimethylsiloxane to a dynamic mixer, Vacuumize until the vacuum degree is -0.1MPa, stir for 30min;

[0056] (2) Add crosslinking agent (methyltrimethoxysilane) and catalyst (tetrabutyl titanate) to the mixture obtained in step (1) in sequence, and vacuumize to -0.1MPa after each substance is added , stirred for 20 minutes, until the last substance was added and mixed evenly, then discharged, packaged, and silicone coating glue was obtained.

Embodiment 3

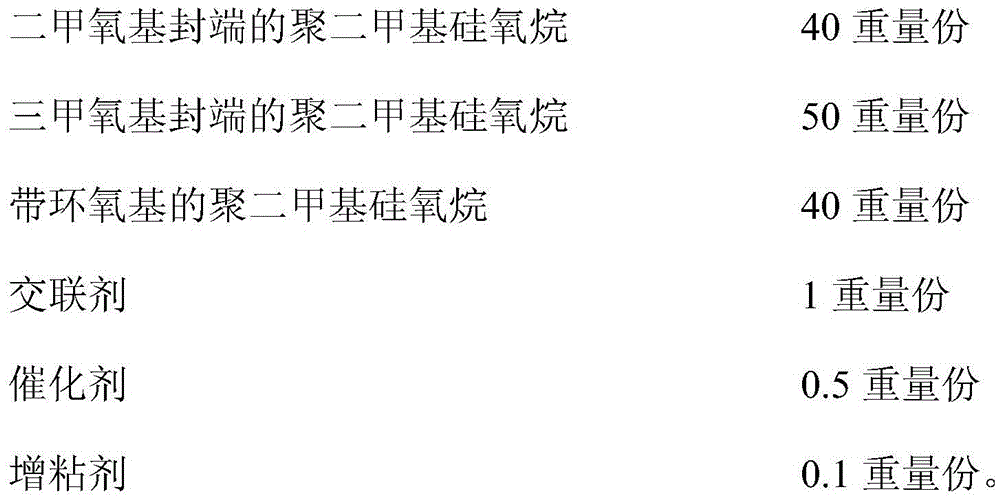

[0058] In this embodiment, the silicone coating glue contains the following components by weight:

[0059]

[0060]

[0061] Its preparation method specifically comprises the following steps:

[0062] (1) Add dimethoxy-terminated polydimethylsiloxane, trimethoxy-terminated polydimethylsiloxane, and epoxy-grouped polydimethylsiloxane to a dynamic mixer, Vacuumize until the vacuum degree is -0.097MPa, stir for 20min;

[0063] (2) Add crosslinking agent (vinyltrimethoxysilane), catalyst (tetrabutyl titanate) and tackifier (silane coupling agent with epoxy group) successively to the mixture obtained in step (1), After each substance is added, vacuumize to -0.095MPa, and stir for 30 minutes until the last substance is added and mixed evenly, then discharged, packaged, and silicone coating rubber is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| storage stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com