Tipping paper drum wheel device with automatic cleaning function

A tipping paper drum and automatic cleaning technology is applied in the direction of cleaning methods using tools, manufacturing paper cigarettes, cleaning methods and utensils, etc. It can solve problems such as affecting production progress, cumbersome and complicated steps, and poor cutting, and achieve effective effects. Long time, improve cleaning effect, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

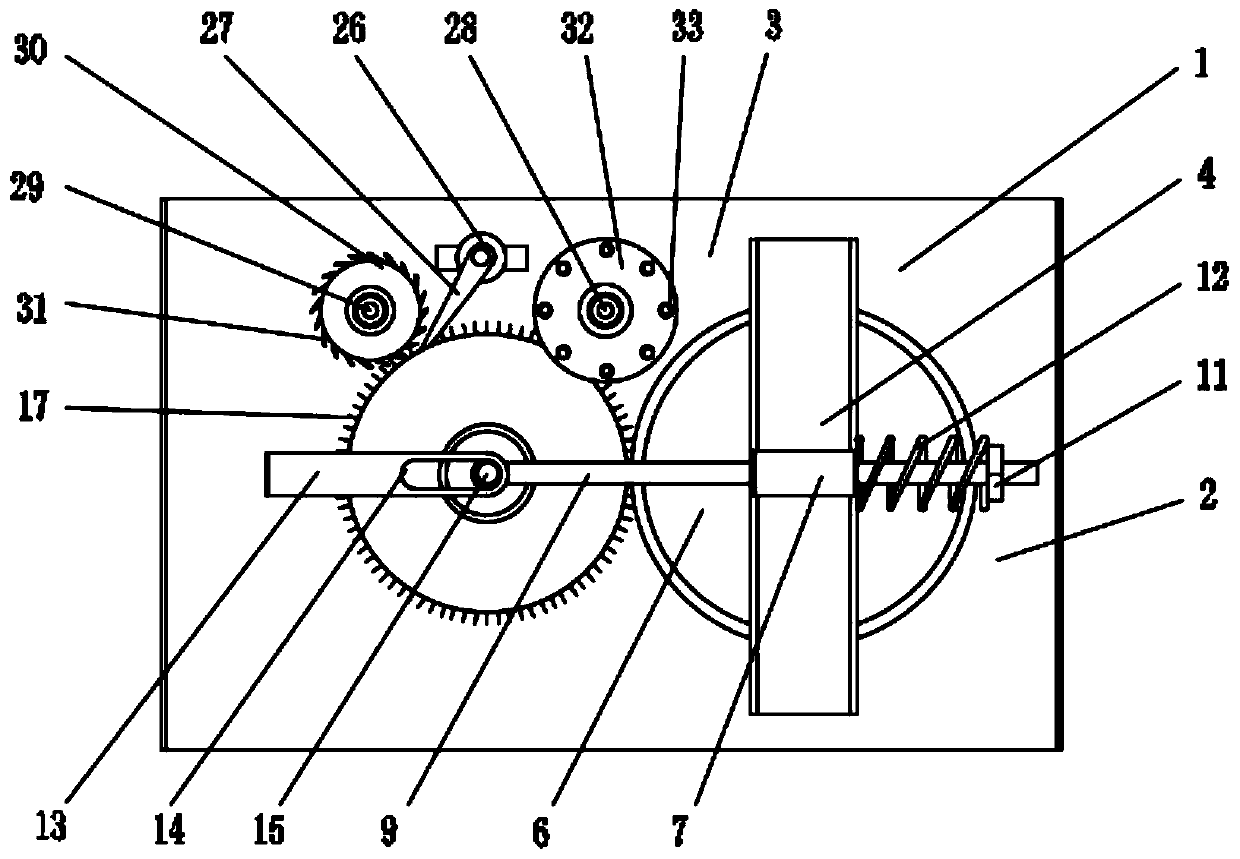

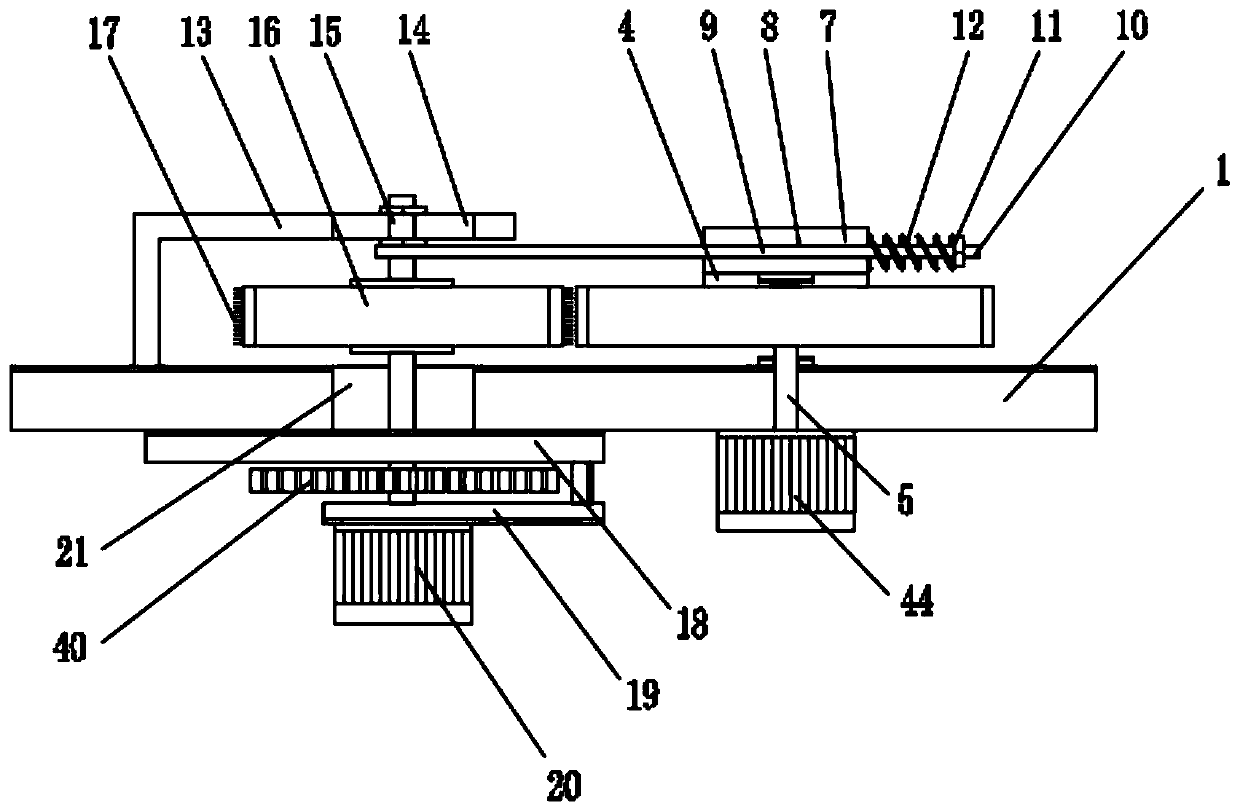

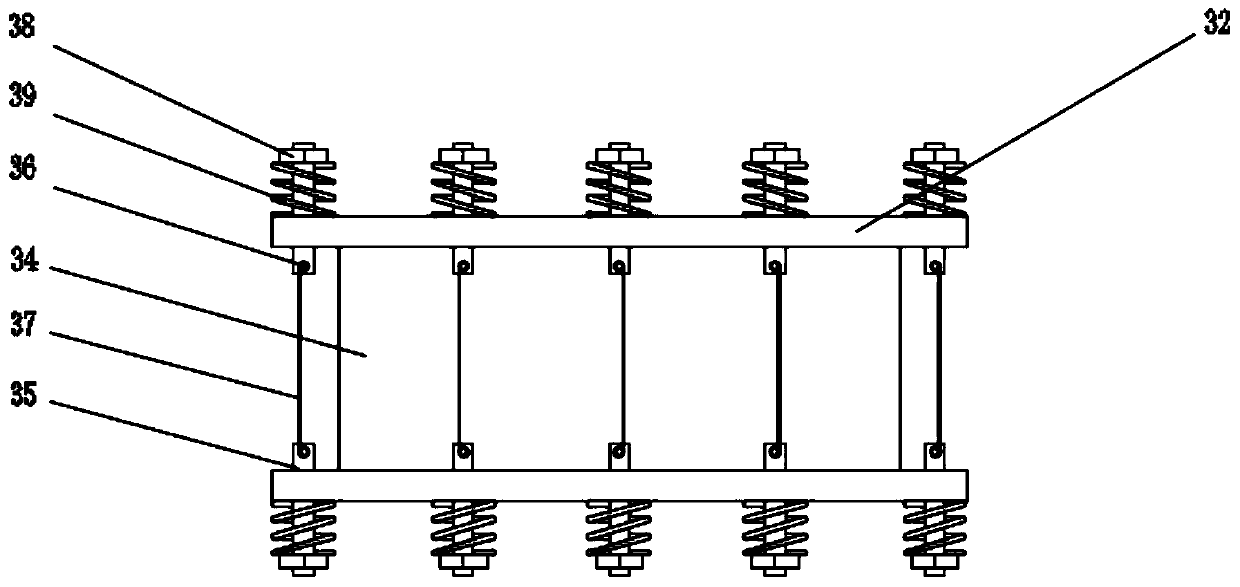

[0022] Example: such as Figure 1-5 As shown, a kind of tipping paper drum device with automatic cleaning function of the present invention comprises clamping mechanism 2 and cleaning mechanism 3, and described clamping mechanism 2 comprises mounting plate 1 and moving slide plate 18, and described mounting plate 1 and The mobile slide plate 18 is adjacent to the left and right, and two slide rails 25 are fixedly installed on one side of the installation plate 1, and two slide bars 41 are fixedly installed on the opposite side of the mobile slide plate 18 to the installation plate 1, and the installation plate No. 1 mobile slot 21, No. 2 mobile slot 22, No. 3 mobile slot 23 and No. 4 mobile slot 24 are provided in the 1, and No. 2 motor 44 is fixed on one side of the mobile slide plate 18 and is located on the outer wall of the mounting plate 1. The output shaft of the No. 2 motor 44 is fixedly connected with the No. 1 rotating rod 5 passing through the mounting plate 1. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com