Process for machining special winding gears for transformers with roll iron cores

A processing technology and transformer technology, applied in the field of winding gear processing technology for winding iron core transformers, can solve the problems of long installation time, low production efficiency, affecting coil winding, etc., and achieve long service life, convenient winding, Guaranteed hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

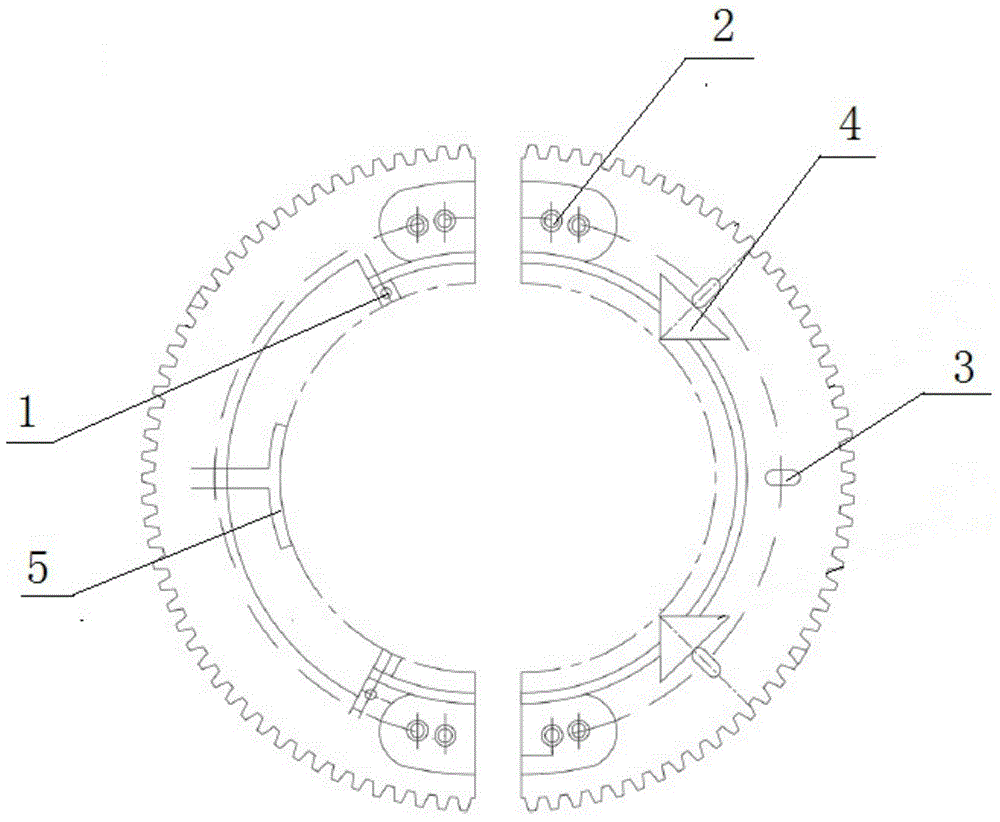

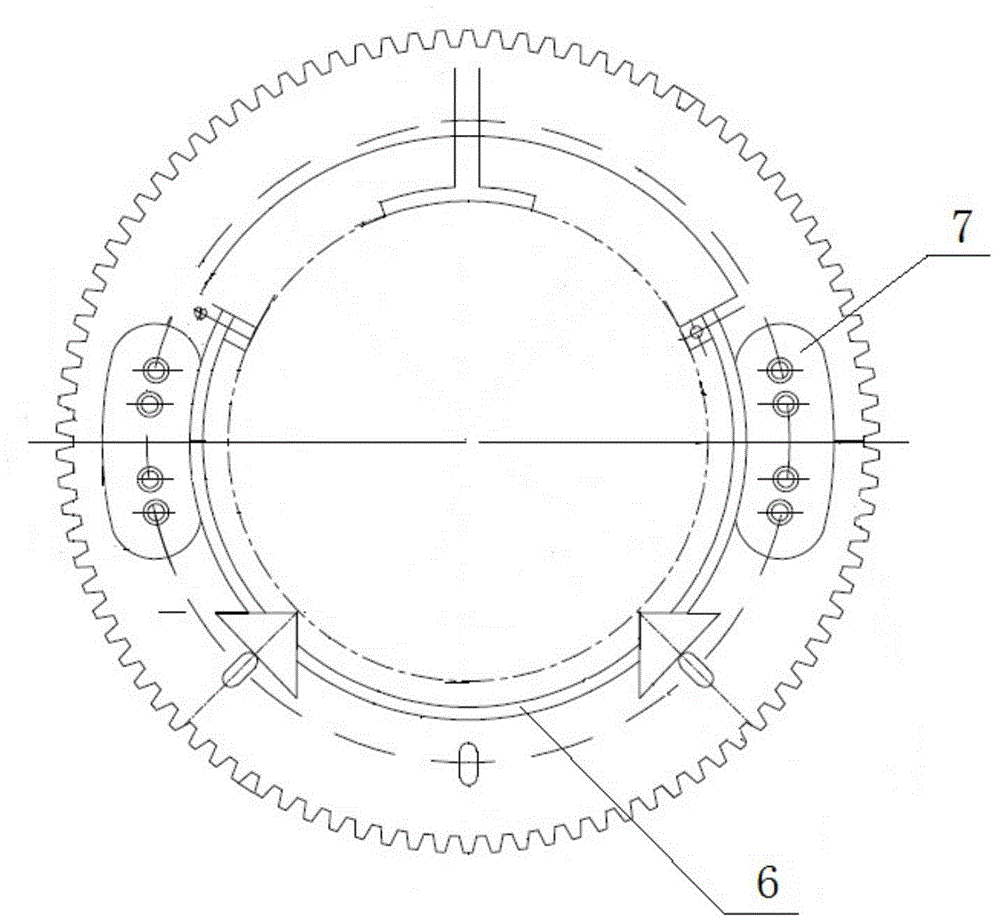

[0027] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

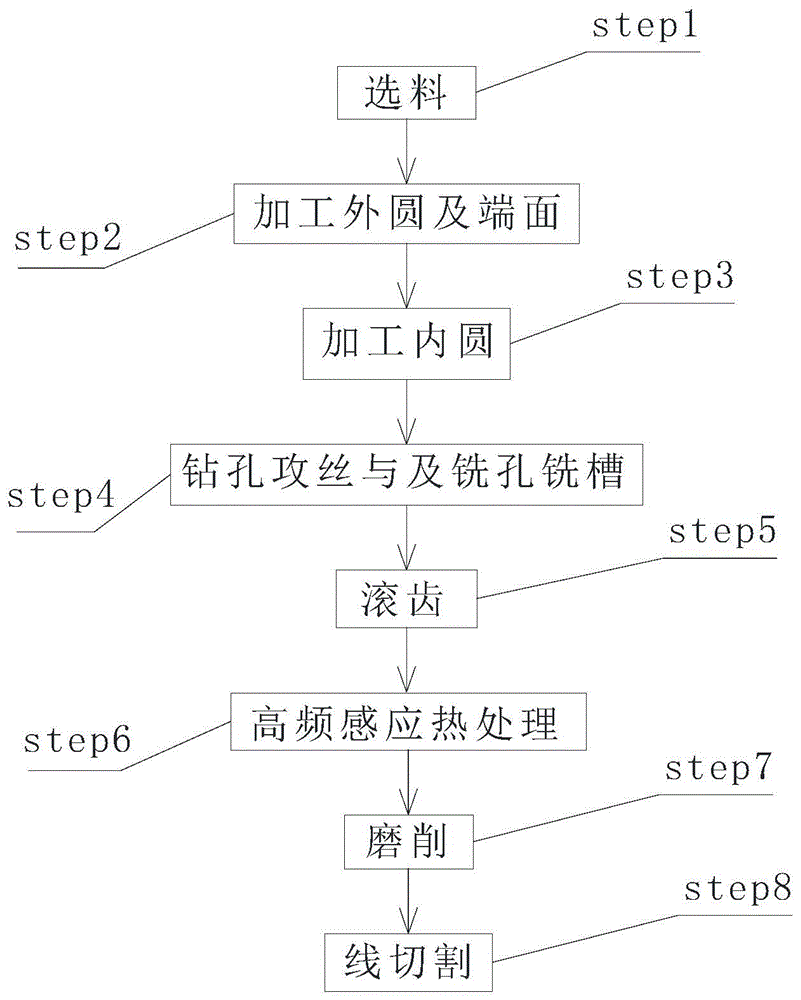

[0028] Such as Figure 1-Figure 3 As shown, a special winding gear processing technology for wound core transformers includes the following steps:

[0029] The first step step1 is material selection. Firstly, No. 45 steel is selected as the workpiece to be processed according to the part requirements, in preparation for the subsequent process. Then determine the positioning center to ensure that the size meets the requirements of the workpiece; finally drill a fixing hole in the positioning center to fix the workpiece when processing it later.

[0030] The second step step2 is to process the outer circle and end face, and rough the outer circle of the workpiece on the lathe to remove the excess margin of the blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com