Bobbin dyeing process of elastic velvet feather yarn

A technology of velvet and feather yarn, which is applied in the field of cylinder dyeing technology. It can solve the problems of decreased yarn strength, white streaks, and difficulty in dyeing evenly, so as to achieve uniform and full dyeing, improve production efficiency, and prolong the heat preservation time of dip dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment is a tube dyeing process of elastic velvet feather yarn, comprising the following process steps:

[0027] 1) Yarn preparation steaming: Steam the elastic velvet feather yarn from the textile factory at high temperature, the steaming temperature is 150-160°C, and the steaming time is 7-8 minutes, so that the yarn is pre-shrunk and soft and moist ,spare.

[0028] 2) Winding: the elastic velvet feather yarn steamed in step 1) is wound on the dyeing cylinder along the direction of the feathers, and the direction of the winding of the feathers is from the small end to the large end of the dyeing cylinder; The density is 0.35~0.37g / m 3 , The winding density arm pressure and tension are determined through multiple tests.

[0029] 3) Cage loading: put the bobbin wound in step 2) into the sarong from bottom to top, and the big end of the bobbin is downward and the small end is upward, and the connection between the upper bobbin and the lower bobbin is ac...

Embodiment 2

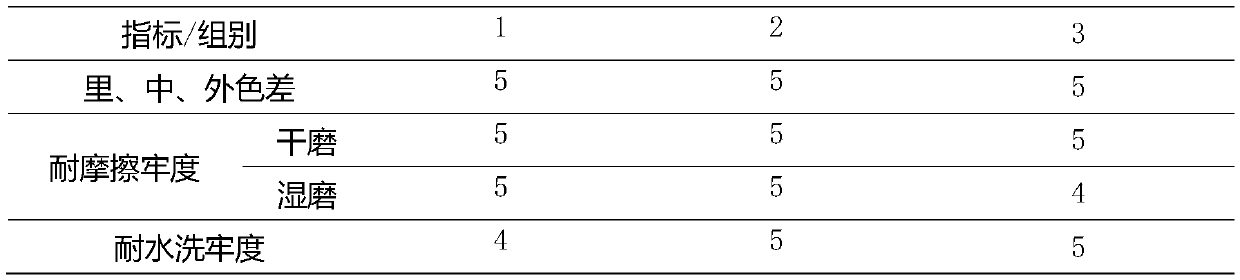

[0038] Three groups of elastic velvet feather yarns dyed in Example 1 were taken, and performance tests were carried out respectively, including the measurement of inner, middle and outer color difference, the measurement of fastness to rubbing and the measurement of fastness to washing. Among them, the measurement of inner, middle and outer color difference is evaluated according to the grade 5 evaluation standard of gray sample card; the test of fastness to rubbing is measured according to the provisions of GB / T3920-2008, and the test of fastness to washing is carried out according to the provisions of GB / T5703-1997 To measure. The results are shown in Table 1, where Level 5 is the best and Level 1 is the worst.

[0039] Table 1. Embodiment 1 gained elastic velvet feather yarn performance

[0040]

[0041]It can be seen from the above that the various performance indexes of the elastic velvet feather yarn dyed in Example 1 all reach the best. It overcomes the problem of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com