Winding frame

A winding frame and turntable technology, which is applied in the field of winding frames for network cables, can solve the problems of increasing labor force and labor time, labor increase, and inconvenient operation, and achieve the effects of convenient operation, floor space saving, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

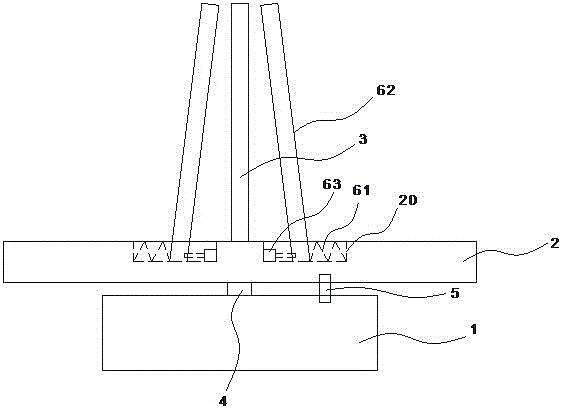

[0012] The present invention as figure 1 As shown, it includes a base 1, a turntable 2, a center rod 3 and several brace mechanisms, the turntable 2 is movably connected above the base 1, and the center rod 3 is fixed at the center of the turntable 2;

[0013] Several said strut mechanisms are arranged on said turntable 2, and are located in the periphery of said central rod 3 in a ring shape, and said brace mechanisms include a strut 62, a hydraulic cylinder 63, a spring 61 and grooves arranged on the turntable 20, the spring 61, the strut 62 and the hydraulic cylinder 63 are sequentially arranged in the groove 20, and the spring is located outside the groove.

[0014] The struts 62 are arranged obliquely toward the central rod 3 , so that several struts are tapered with a small top and a large bottom; so that several struts are arranged in a conical shape, which is convenient for socketing coils of different diameters.

[0015] A pin groove is provided at the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com