Vertical winding die of stereoscopic reeled iron core with voltage of 110kV and more

A technology of three-dimensional wound iron core and winding mold, which is applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., to achieve the effects of reducing manufacturing costs, convenient operation and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

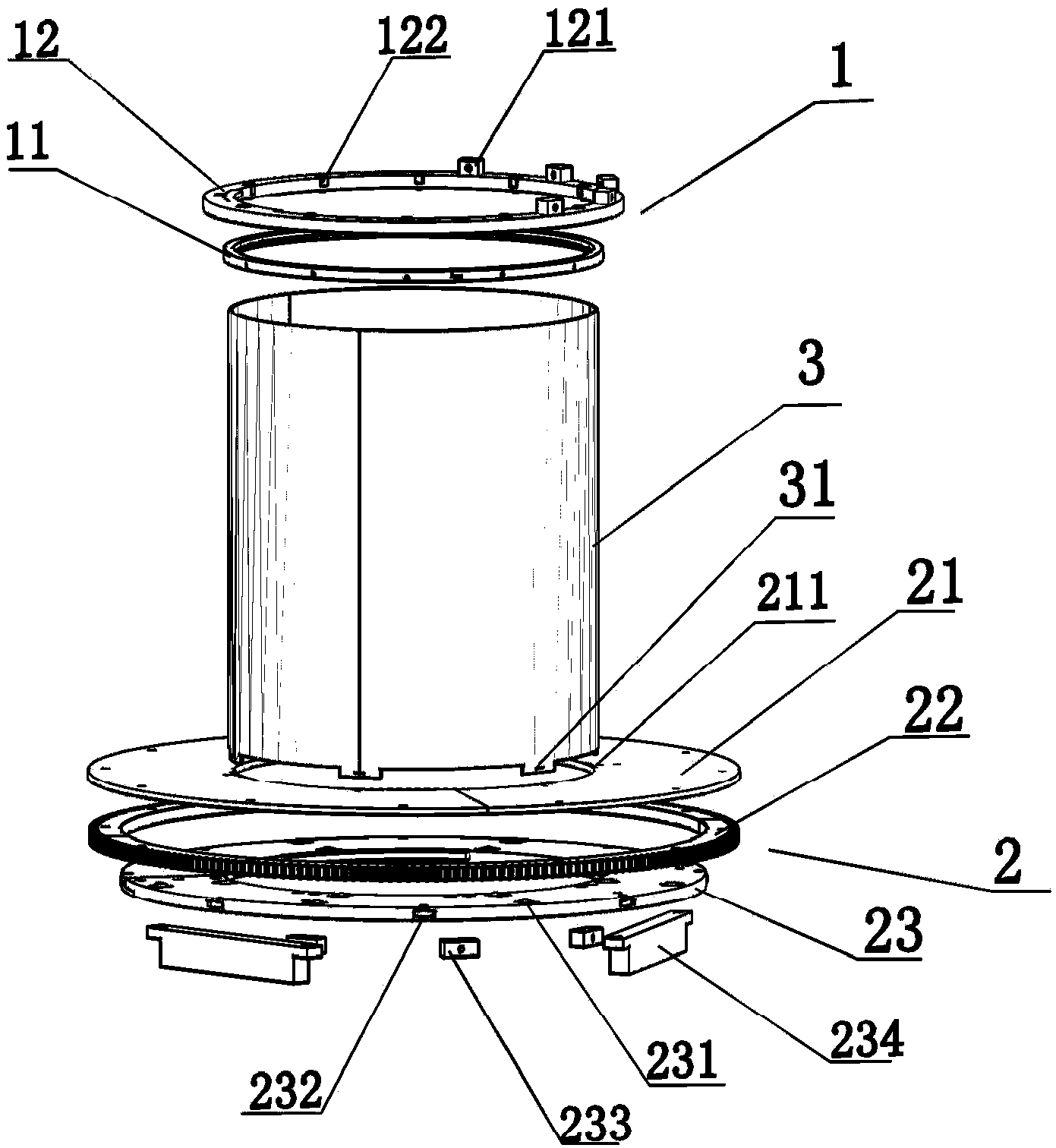

[0014] refer to figure 1 , a vertical winding die for a 110kV and above three-dimensional winding core of the present invention, comprising an upper die 1, a lower die 2 and a winding die 3, the upper die 1 includes an upper die inner ring 11 and an upper die outer ring 12, The inner ring 11 of the upper die and the outer ring 12 of the upper die are both half-detachable annular structures, and the half-detachable structures are connected by bolts, and the outer ring 12 of the upper die is rotatably arranged on the periphery of the inner ring 11 of the upper die; Outer ring 12 is provided with upper die positioning nut 121 and upper die positioning shaft 122, upper die outer ring 12 is used to fix upper die inner ring 11, and multiple upper die positioning shafts 122 are evenly distributed on the inner side of upper die outer ring 12 On the wall, the upper die inner ring 11 is guided to slide and rotate along the upper die positioning shaft 122, and the upper die positioning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com