Stator assembly for asynchronous motor and method for making same

A stator assembly, asynchronous motor technology, applied in asynchronous induction motors, manufacturing motor generators, prefabricated windings embedded in motors, etc., can solve the problems of low motor production efficiency, difficult winding, slow winding speed, etc., to achieve production efficiency High, simple structure, convenient winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

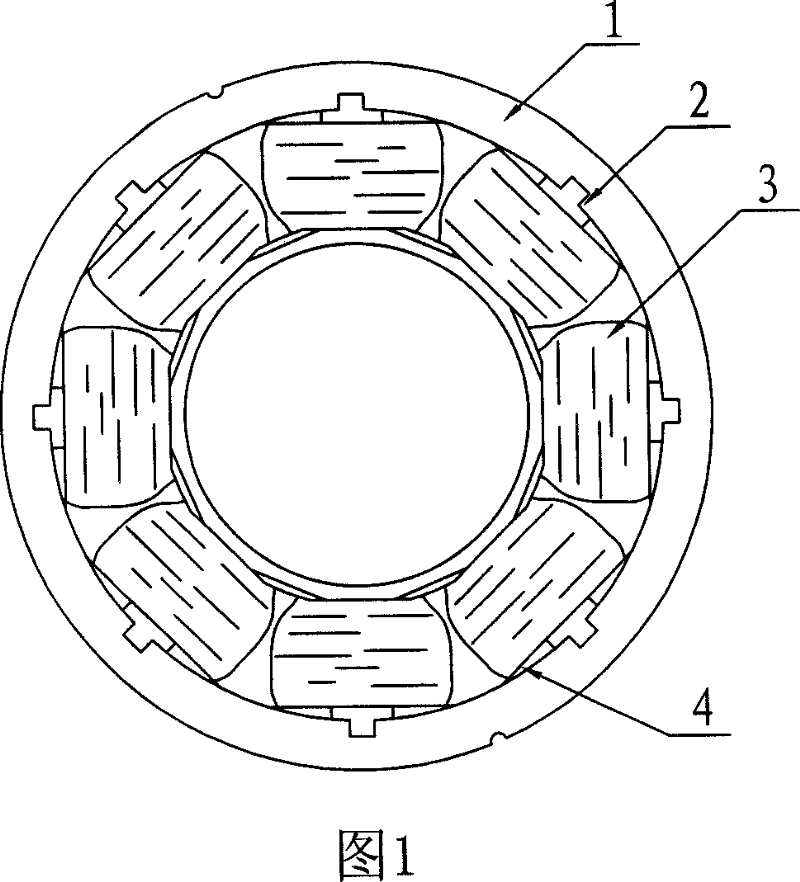

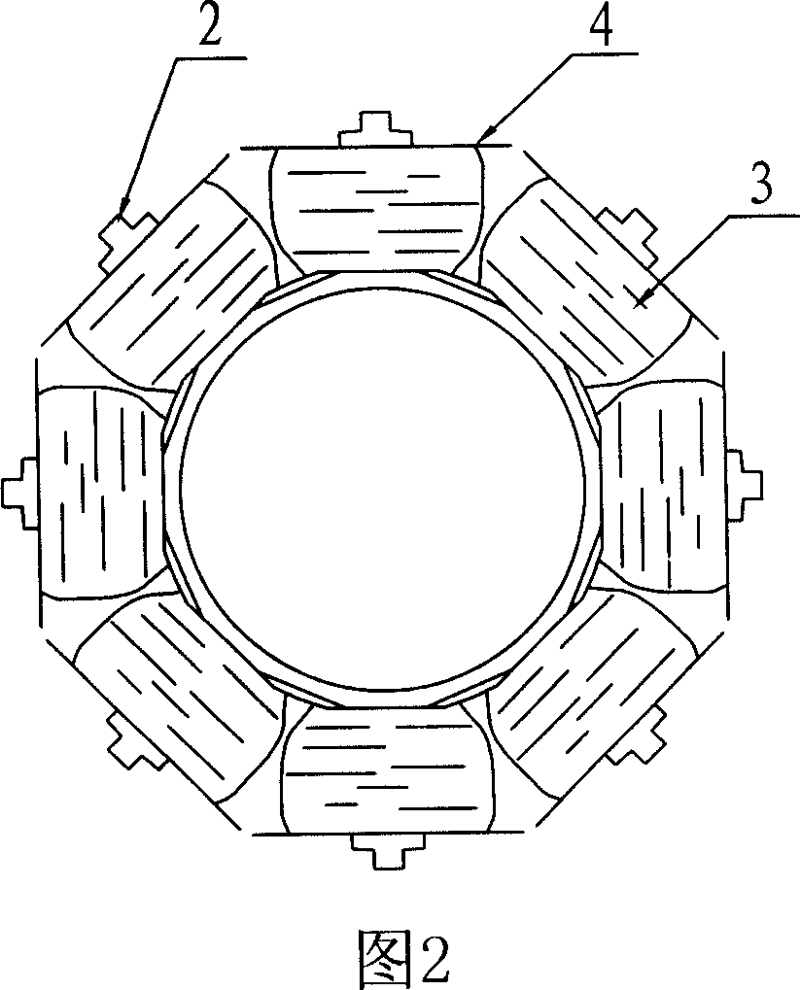

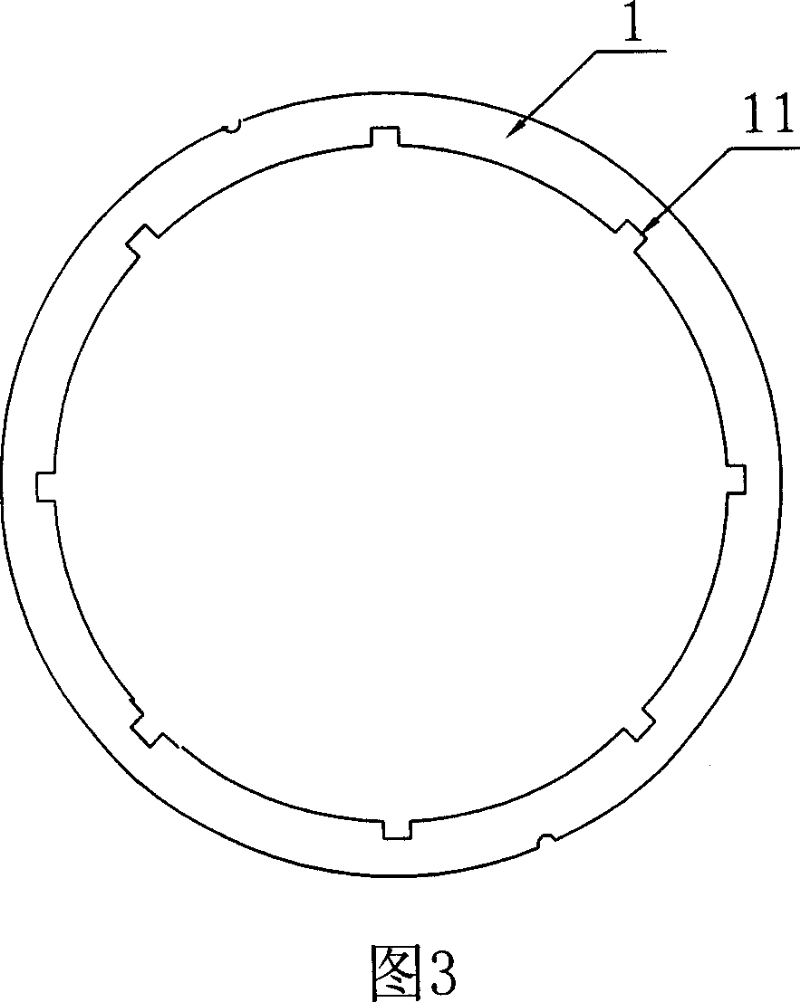

[0021] As shown in Figures 1-6, the present invention is a stator assembly structure of a novel asynchronous motor, including a stator core, a winding 3 and an insulating frame 4. The stator core includes a slotted tooth part 2 and an outer yoke part 1. The slotted tooth part 2 is in the shape of a wheel spoke, and a number of teeth 21 are arranged in the radial direction. The insulating frame 4 wound with winding 3 is set on the teeth 21 of the slotted tooth part. , The outer yoke part 1 is in the shape of a ring, and is installed on the tooth part 2. The slot tooth part 2 is installed in cooperation with the keyway of the outer yoke part 1.

[0022] The grooved tooth part 2 is provided with eight teeth 21 which are equally divided in the radial direction, and each tooth is provided with a boss 211. Correspondingly, the outer yoke part 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com