High-power rectifier transformer of charger

A rectifier transformer, high-power technology, applied in the field of transformers, to achieve the effects of improving ventilation and heat dissipation, good mechanical strength against short-circuit, and convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings.

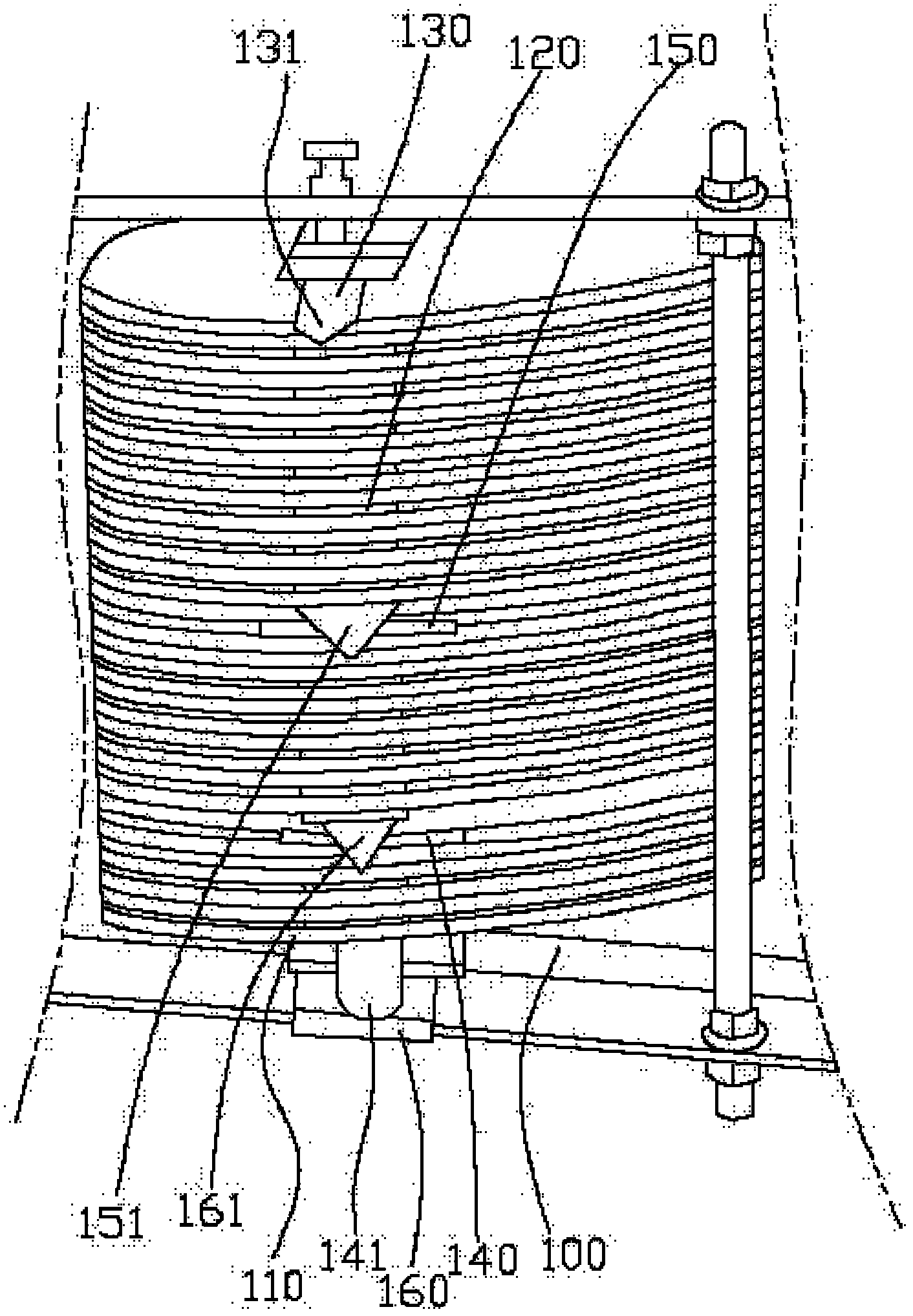

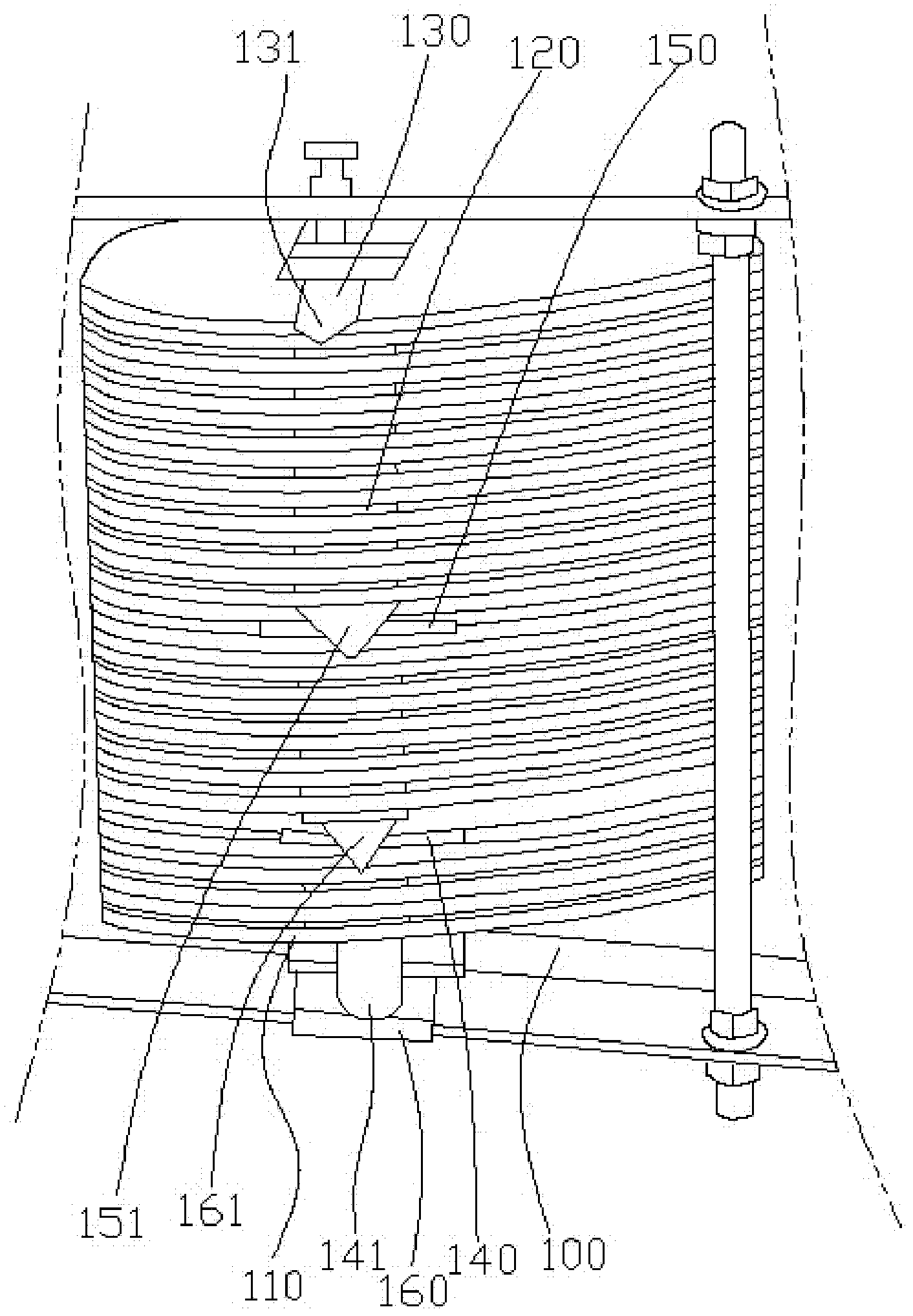

[0010] see figure 1 , a high-power rectifier transformer for a charger, including an iron core column (not shown in the figure), a primary coil (not shown in the figure) and a secondary coil 100 wound on the iron core column, and the secondary coil 100 The side coil 100 is divided into several layers of wire cakes, and the wire cakes are separated by 2-3mm insulating bakelite blocks 120; the side coil 100 is provided with two coil output terminals 130, 140 and two intermediate taps 150, 160, the coil output terminals 130, 140 are arranged at the two ends of the secondary coil 100, and the two intermediate taps 150, 160 are arranged in the middle position of the secondary coil 100; at the coil output terminals 130, Output terminals 131 , 141 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com