High-frequency transformer of spot welding machine

A high-frequency transformer and spot welding machine technology, applied in the field of transformers, can solve the problems of large loss, large loss, and temperature rise of the transformer, and achieve the effects of reducing copper circuit loss, reducing leakage inductance, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

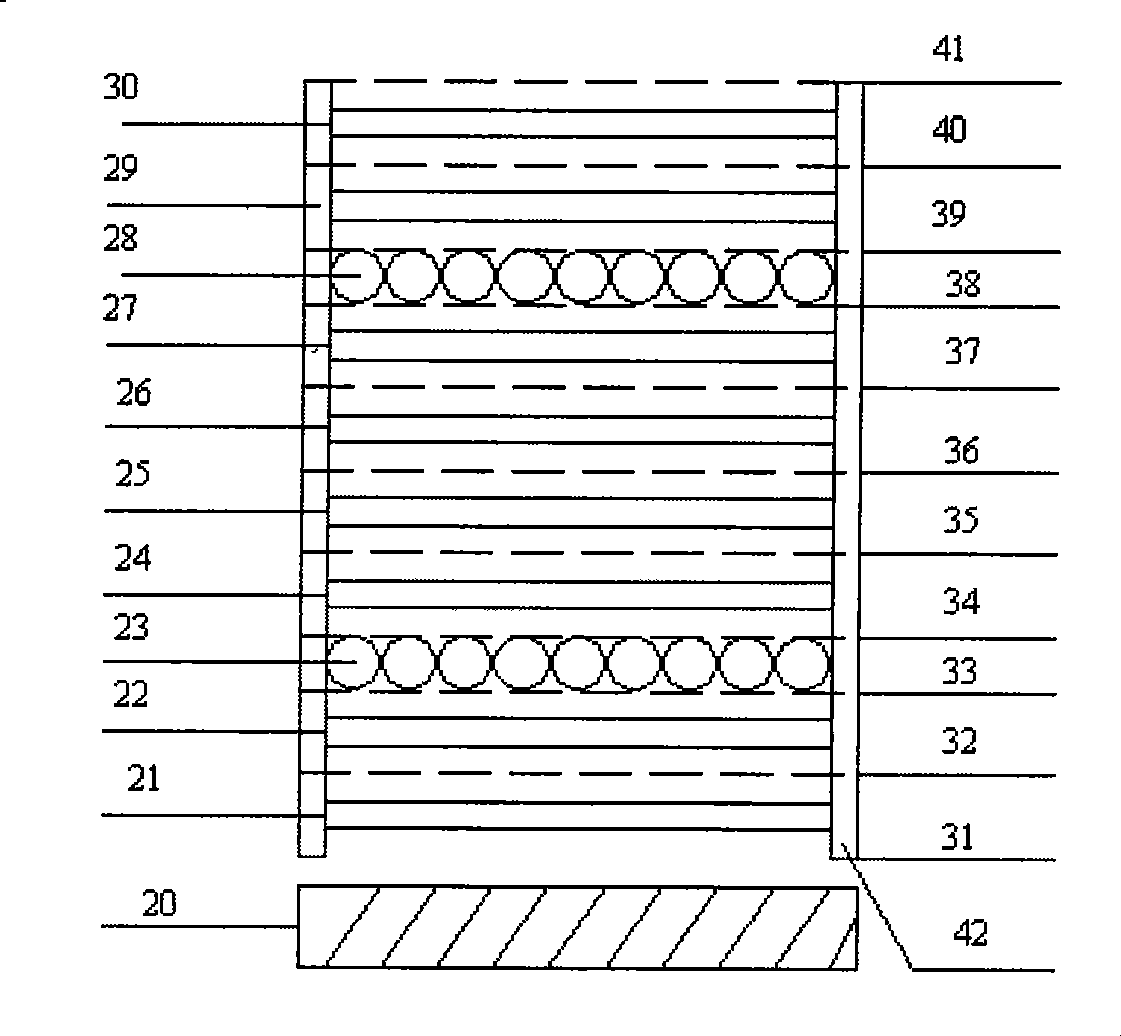

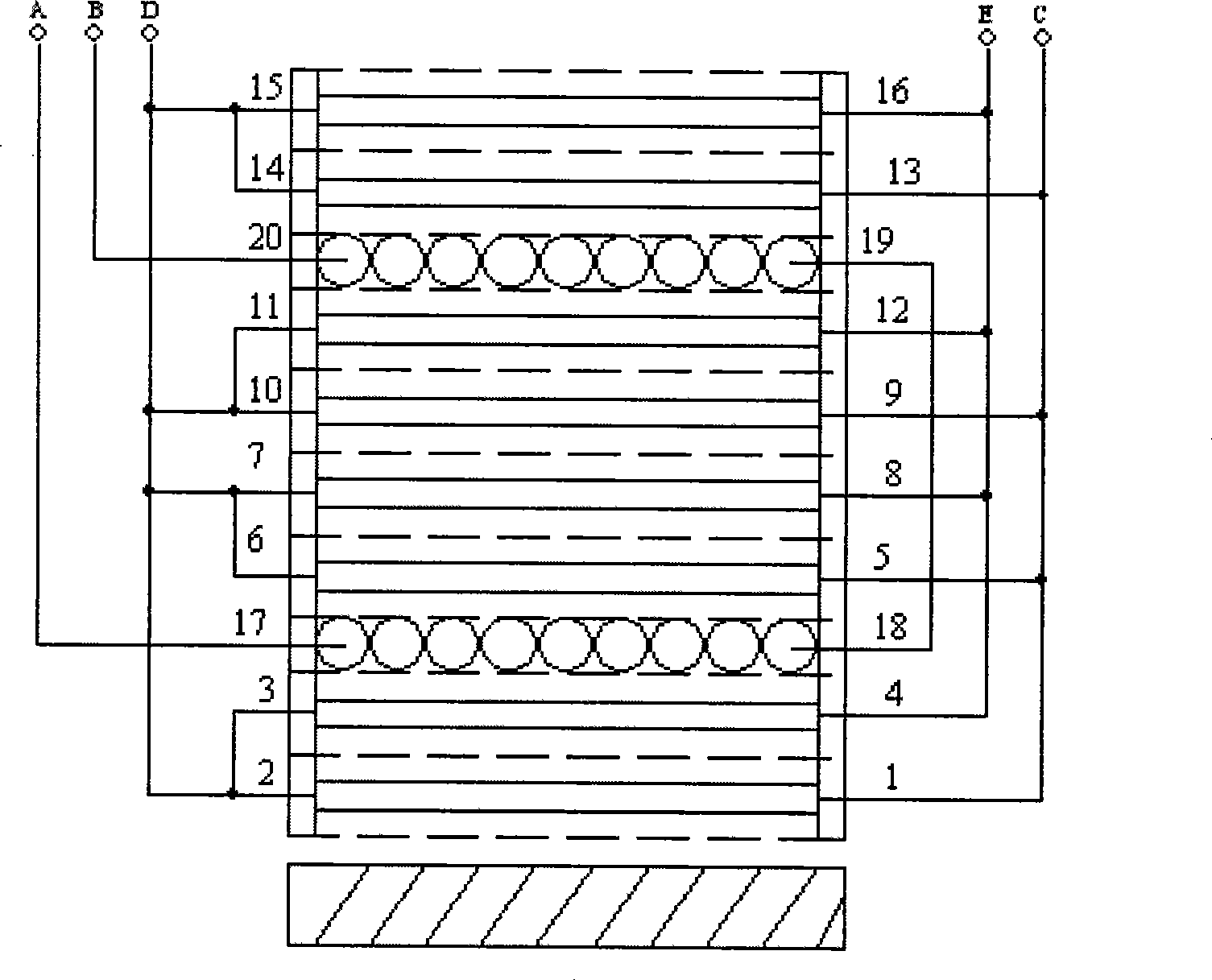

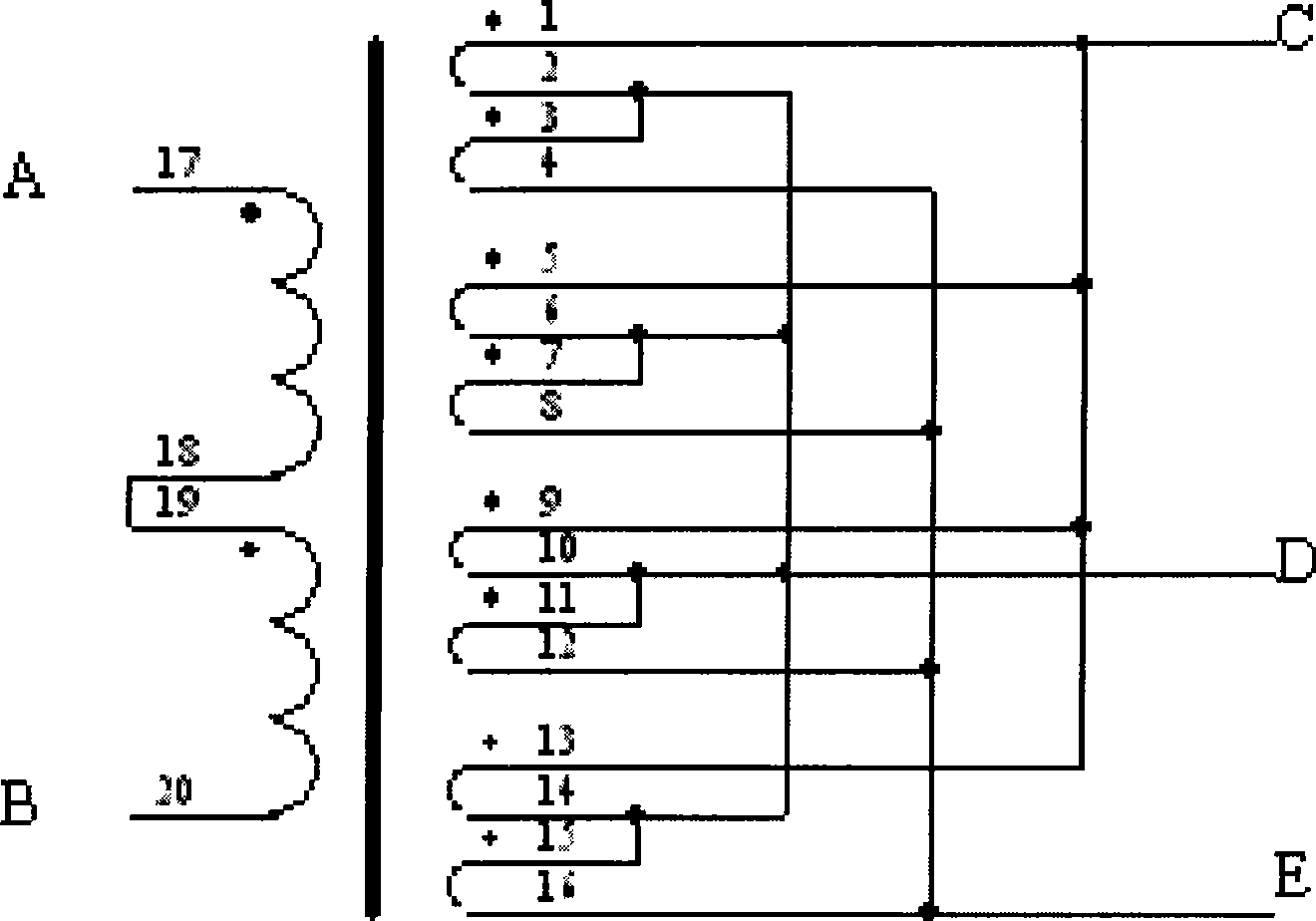

[0018] The guiding ideology of the present invention is: reduce the leakage inductance of the transformer, which can reduce the requirements for IGBT stress and improve the output power; reasonable selection of materials, strict manufacturing process, to ensure the consistency of transformer parameters, such as transformer inductance, leakage inductance, The difference in parameters such as the air gap is not greater than (0.5-2%), and the effective parallel connection of multiple transformers is achieved, thereby achieving the purpose of increasing the output power rate. Effectively handle the heat dissipation problem of the transformer's lead legs and improve the duty cycle of the transformer. Concrete practice of the present invention is:

[0019] ① Select the appropriate magnetic core according to the size of the output power, usually the EE type magnetic core is easy to reduce the leakage inductance;

[0020] ②The primary section and the secondary winding are alternately...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com