Liquid cooling auto-excitation-type eddy current retarder without electric brush structure

An eddy current retarder and retarder technology, applied in the direction of electric brake/clutch, asynchronous inductive clutch/brake, motor, etc., can solve the problem of limiting the improvement of braking torque and continuous braking of self-excited retarder. Time, low life, inability to effectively dissipate the heat of the eddy current induction body of the retarder, etc., to achieve the effect of small braking torque recession, high reliability, and eliminating the need for brush devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

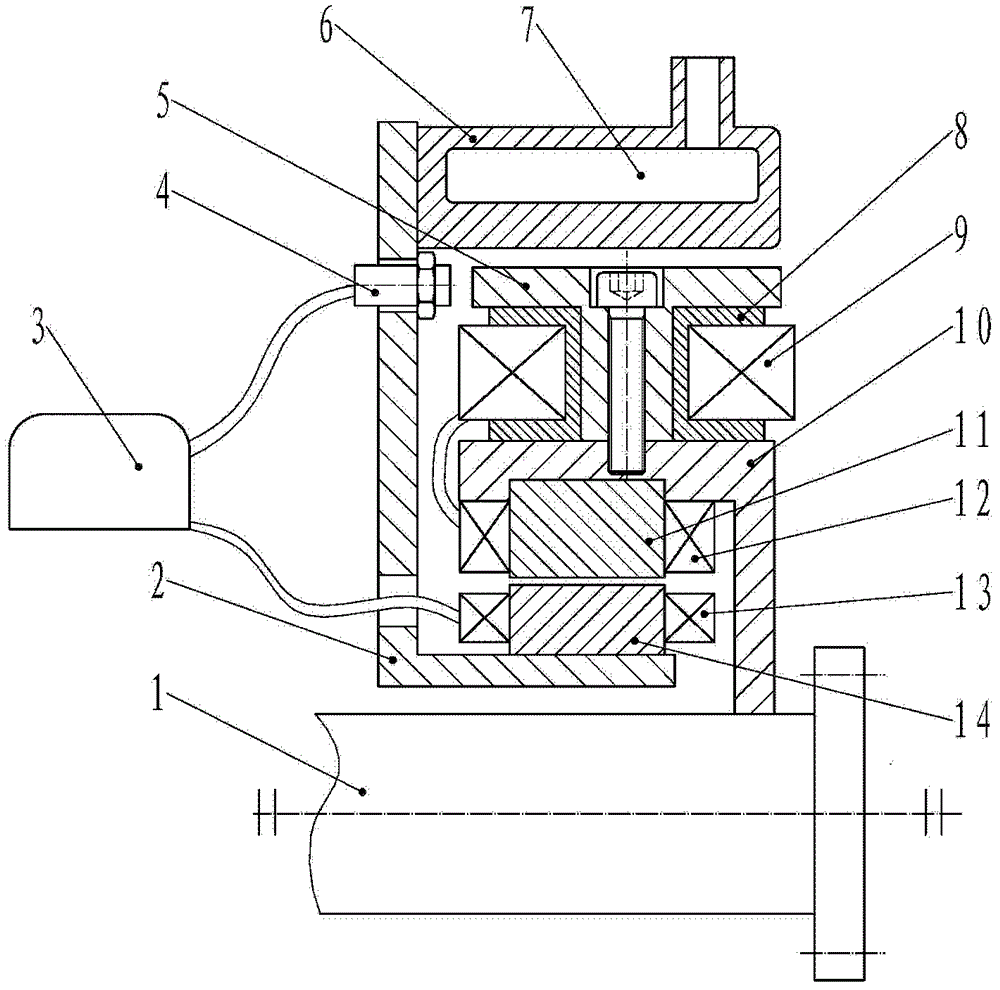

[0019] like figure 1 As shown, the stator 6 of the retarder in the embodiment of the present invention is provided with a water channel 8, which is placed on the outermost side of the retarder. Both the retarder stator 6 and the speed sensor 5 are fixed on the retarder fixing frame 2, and the speed sensor 4 is used for measuring the speed of the retarder. The retarder coil 9 and the coil frame 8 are fixed in the electromagnet core 5, and 8-12 electromagnet cores 5 are evenly distributed on the outer circumference of the iron core holder 10, and the outer diameter of the electromagnet core 5 and the inner diameter of the stator water jacket 6 keep 0.5-1.5 mm clearance. The core holder 10 is fixed on the transmission shaft 1 and rotates together with the transmission shaft 1 . The generator armature iron core 11 is embedded in the inner ring of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com