High temperature resistant declining admixture for oil well cement and preparation method thereof

A technology for oil well cement and high temperature resistance, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as strength recession, and achieve the effects of reducing recession, reducing compressive strength and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

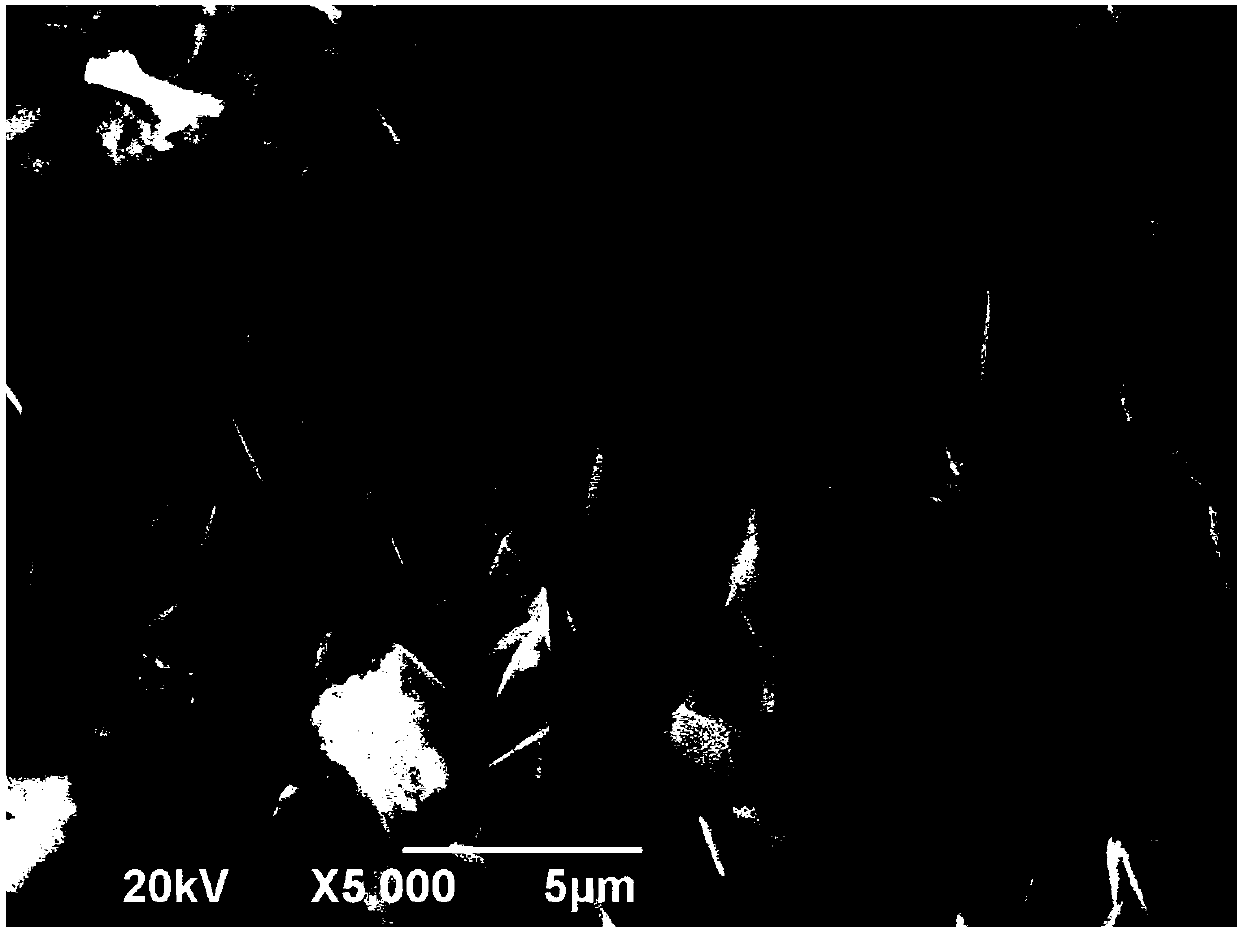

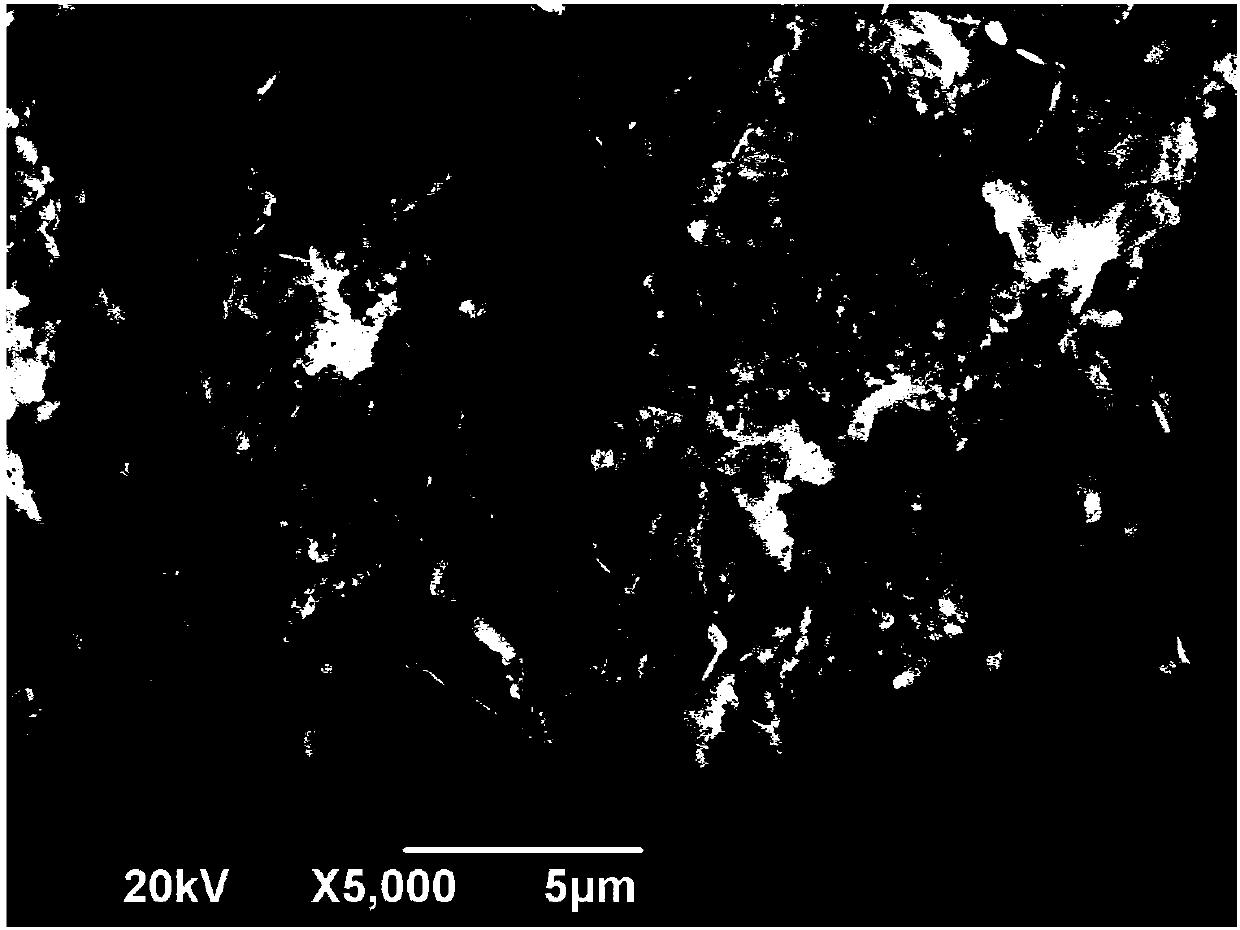

Image

Examples

Embodiment 1

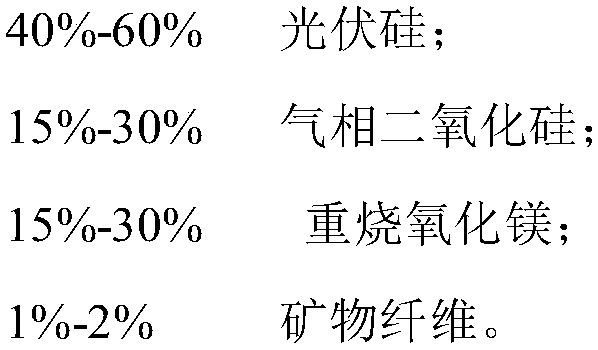

[0024] An oil well cement anti-high temperature decay external admixture, including photovoltaic silicon, fumed silica, dead-burned magnesia and mineral fiber.

[0025] The BHS-70S of the present invention is used as a part of dry ash to prepare a geothermal well cementing slurry system, and the performance of the geothermal well cementing slurry system is tested. The specific composition of the geothermal well cementing slurry system is set as follows:

[0026] The geothermal well cementing cement slurry system includes dry ash, fluid loss reducer BFL-12L, drag reducer BFR-31L and high temperature retarder BRT-22L; among them, BHS-70S of the present invention, micro silicon, high temperature stabilizer BCS -400S and G grade oil well cement together constitute dry ash.

[0027] The high temperature retarder BRT-22L includes AMPS (2-acrylamido-2-methylpropanesulfonic acid), acrylamide, itaconic acid, maleic anhydride, acryloylmorpholine and water.

[0028] High temperature sta...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the ratio of each material of an oil well cement anti-high temperature recession external admixture in this embodiment is different, and the specific ratio in this embodiment is as follows:

[0039] An oil well cement anti-high temperature decay external admixture is composed of 57% photovoltaic silicon, 15% fumed silicon dioxide, 27% dead-burned magnesia, and 1% mineral fiber.

Embodiment 3

[0041] The difference between this embodiment and Embodiment 1 is that the ratio of each material of an oil well cement anti-high temperature recession external admixture in this embodiment is different, and the specific ratio in this embodiment is as follows:

[0042] An oil well cement anti-high temperature decay external admixture is composed of 57% of photovoltaic silicon, 27% of fumed silicon dioxide, 15% of dead-burned magnesia, and 1% of mineral fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com