Liquid cooling self-excitation type eddy current retarder with salient pole structure

A technology of eddy current retarder and retarder, which is applied in the field of automobile retarder with salient pole structure and eddy current retarder, which can solve the problems of inability to dissipate heat into the air, complex structure of retarder, low heat dissipation efficiency, etc. problem, to achieve good heat dissipation, avoid huge impact, and simplify winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

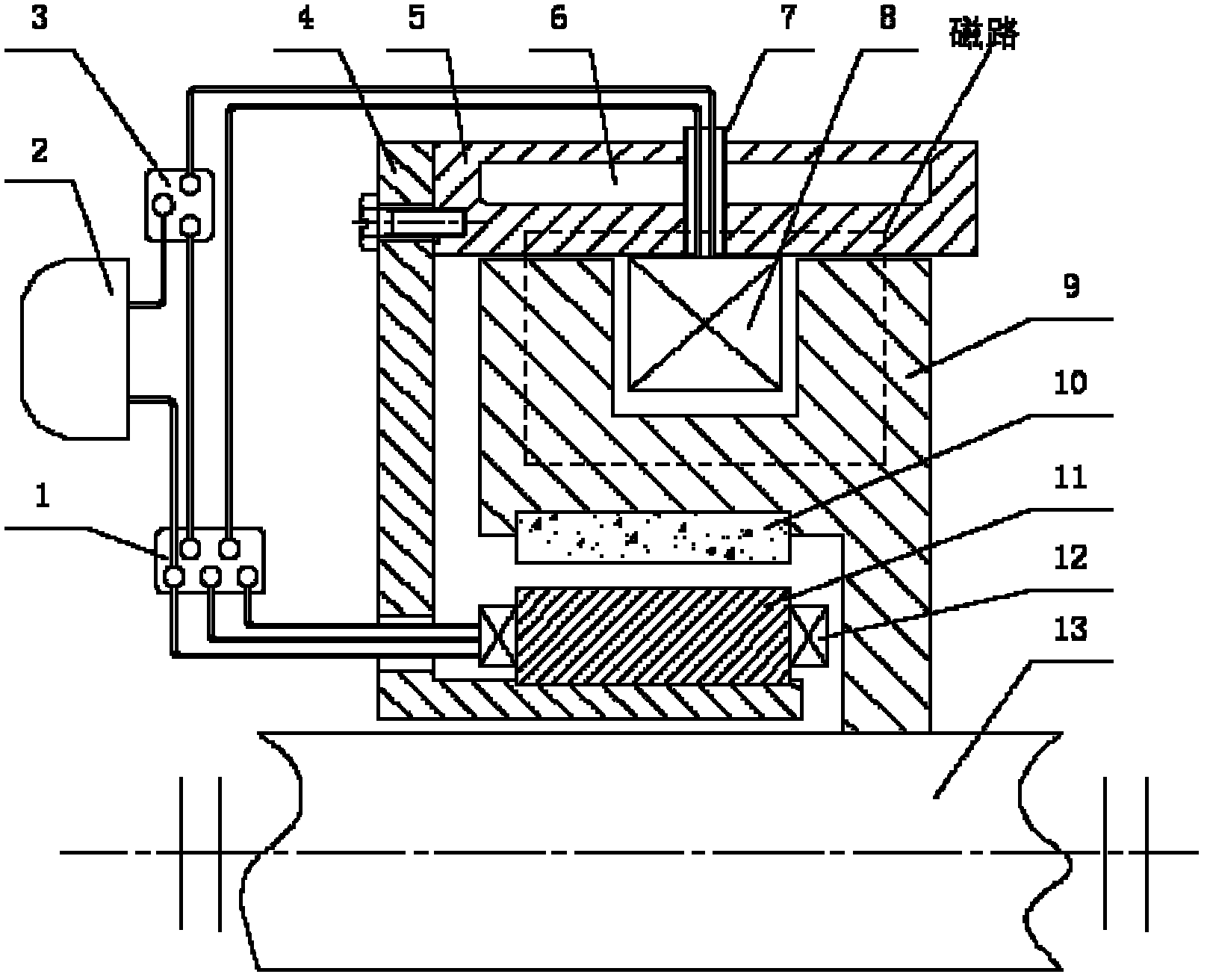

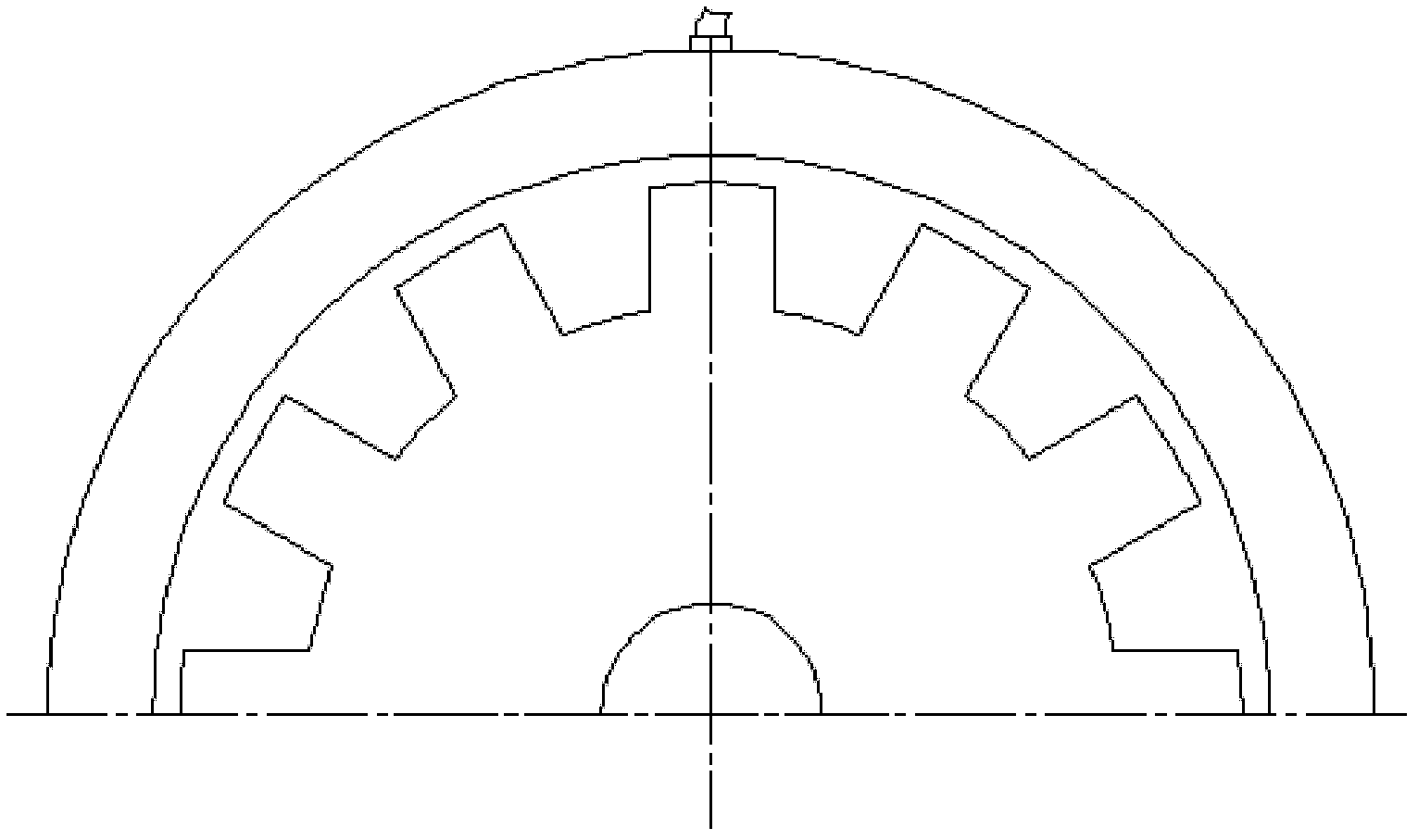

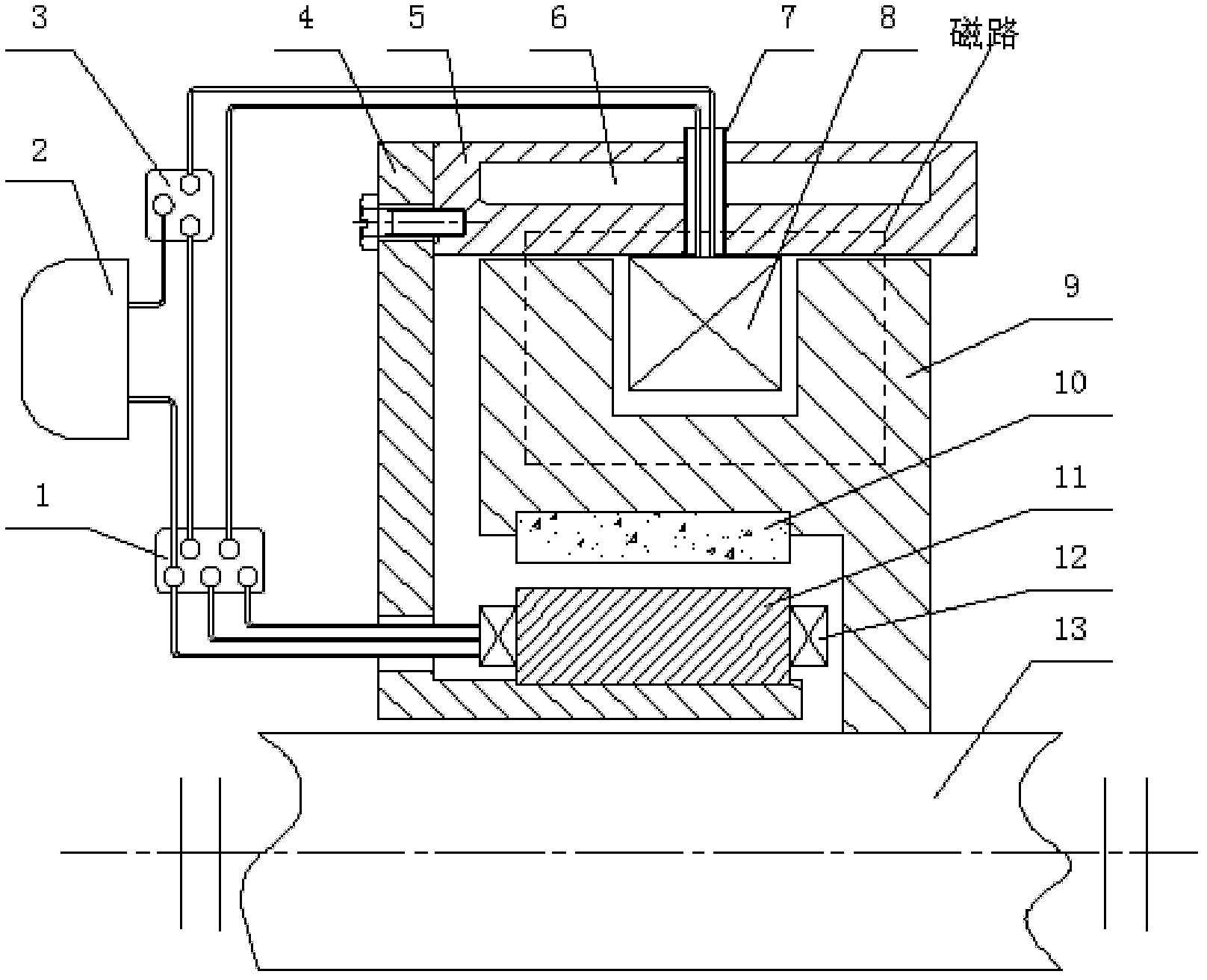

[0019] Such as figure 1 with figure 2 As shown, the retarder rotor 9 of the embodiment of the present invention is connected with the rotating shaft 13 through a spline, and the retarder rotor 9 is a toothed structure such as figure 2 As shown, the axial half section of the toothed turntable is an inverted h shape, and the two protrusions on both sides of the toothed turntable are the two salient poles of the retarder rotor 9 . The concentratedly wound retarder coil 8 is installed between the two salient poles of the retarder rotor 9 and fixed on the inner wall of the retarder stator 5 . The retarder stator 5 is installed on the vehicle frame, and the liquid in the outer water channel 6 of the retarder stator 5 circulates with the engine cooling water, or circulates with the independent cooling device of the retarder. Many pairs of generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com