OLED device

A technology of devices and electron transport layers, which is applied in the field of OLED devices, can solve problems such as device efficiency decline, poor contact surface adhesion, and lifespan decline, and achieve the effects of reducing luminescence quenching, slowing down material deterioration, and slowing down decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

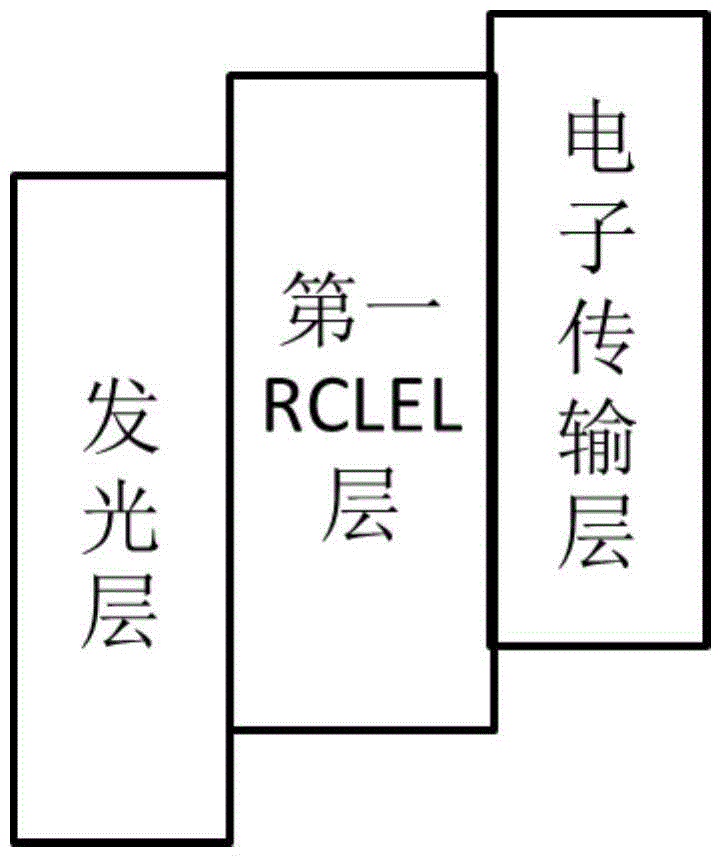

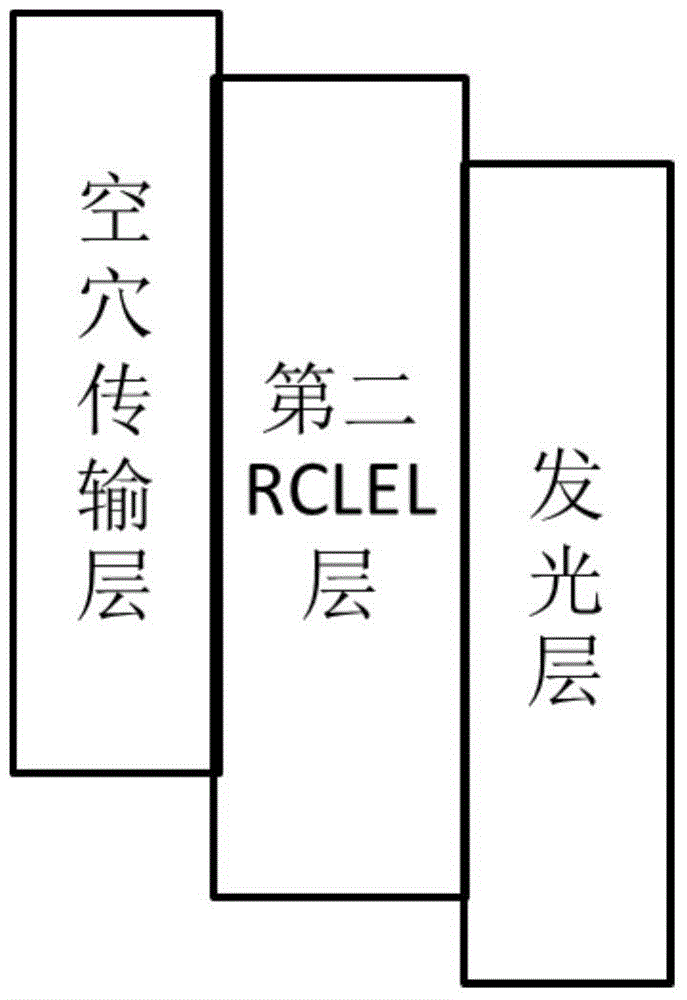

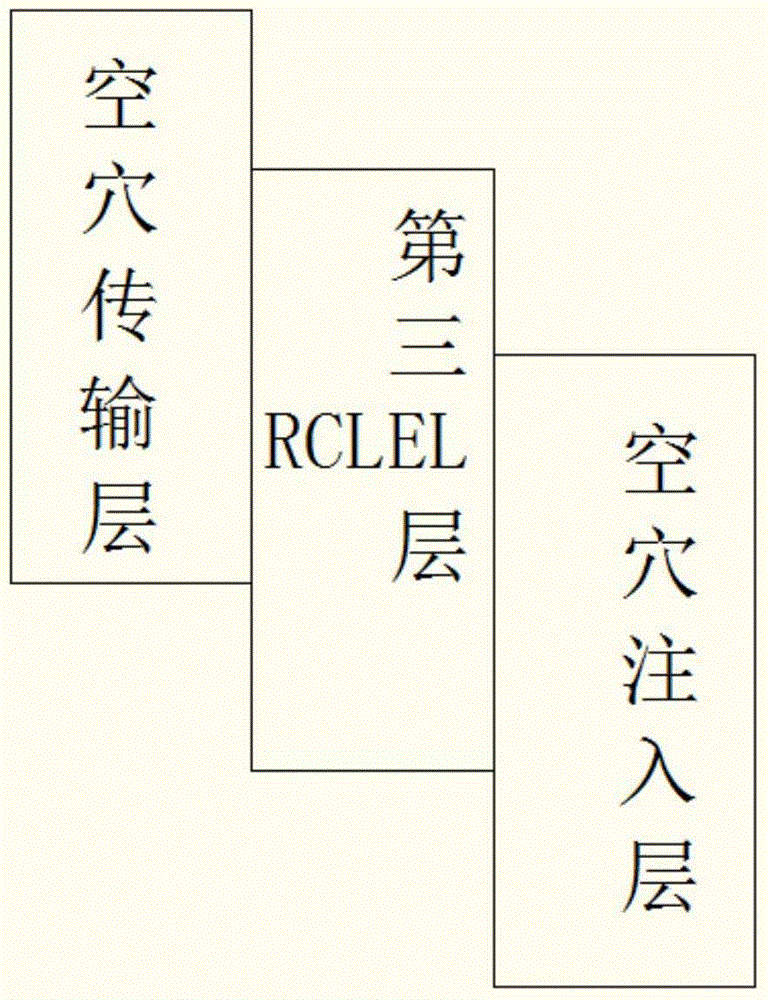

[0030] The core idea of the present invention is to arrange the RCLEL layer between the electron transport layer and the light-emitting layer, and / or the light-emitting layer and the hole transport layer, and / or the hole injection layer and the hole transport layer, due to the electron mobility of the RCLEL layer Faster, it can prevent the accumulation of electrons at the interface of each layer, thereby ensuring the balance of electrons and holes, reducing the formation of recombination centers that do not emit light, thereby improving the life of the device.

[0031] Such as Figure 1a-1c As shown, the present invention has designed a kind of OLED device, and this OLED device comprises electron transport layer, light-emitting layer, hole transport layer and hole injection layer stacked in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com