Charcoal/pottery brake lining manufacturing method for industrial brake

A technology for brake linings and brakes, applied in friction linings, mechanical equipment, etc., can solve the problems of difficult removal of silicon bumps and increase the difficulty of processing, and achieve the effects of easy processing, reduced high-temperature oxidation damage, and reduced processing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

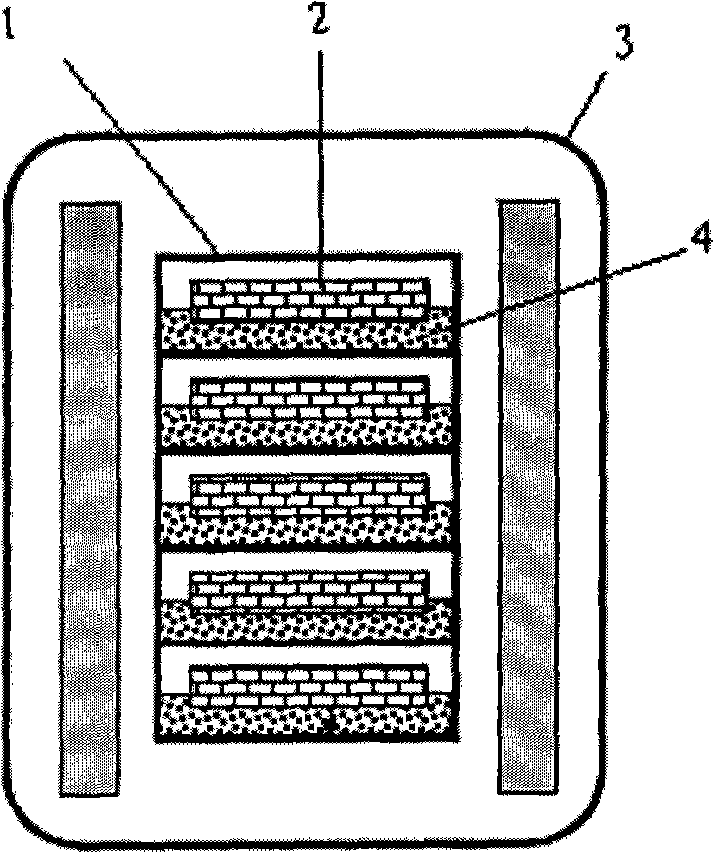

Image

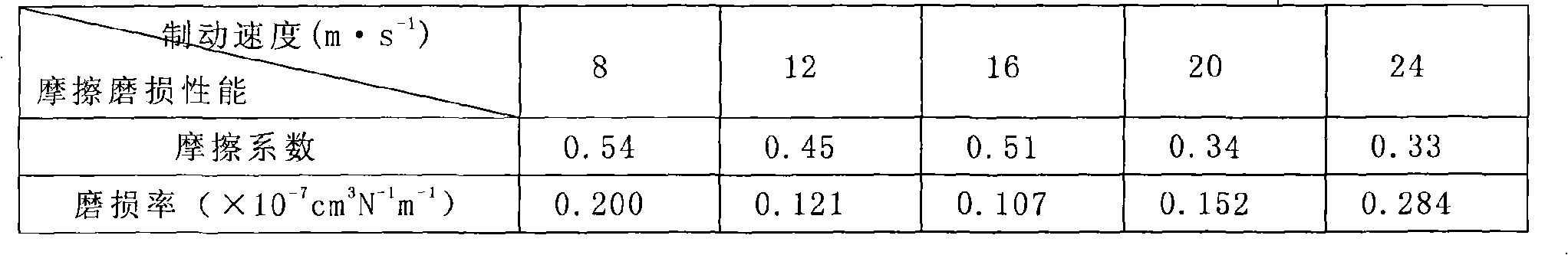

Examples

Embodiment 1

[0041] (1) Firstly, the PAN type T700 (12K) carbon fiber produced by Japan Toray Company (Toray) is used to make tire mesh and no-weft fabric, and the single-layer 0° no-weft fabric, net tire layer, 90° no-weft fabric, The mesh layer is stacked in sequence, and then the density is 0.55g / cm by the method of relay needle punching. 3 carbon fiber prefabricated body;

[0042] (2) Under the protective atmosphere of argon, the preform is subjected to a high-temperature heat treatment before 1800 ° C, the whole time is 5 hours, and the pressure is slightly positive pressure (that is, slightly exceeding the zero scale of the vacuum pressure gauge);

[0043] (3) Propylene is used as the carbon source gas, hydrogen is used as the dilution gas, and the volume ratio of propylene to hydrogen is 1:2. The isothermal chemical vapor infiltration method is used to deposit pyrolytic carbon on the preform at 1100 ° C. After 150 hours of deposition The prepared density is 1.52g / cm 3 Low-density ...

Embodiment 2

[0057] (1) The tire net is made of PAN type T700 (12K) carbon fiber produced by Toray Corporation (Toray) in Japan and stacked layer by layer, and then the carbon fiber bundle is introduced into the carbon fiber bundle perpendicular to the laying direction by the method of relay needle punching. The density is 0.22g / cm 3 Carbon fiber preform;

[0058] (2) Carry out the pre-high temperature heat treatment of the carbon fiber prefabricated body at 1800 ° C, using argon as the protective gas, the whole time is 8 hours, and the pressure is slightly positive pressure (that is, slightly exceeding the zero scale of the vacuum pressure gauge);

[0059] (3) Natural gas is used as the carbon source gas, hydrogen is used as the dilution gas, and the volume ratio of propylene to hydrogen is 1:3. Thermal gradient chemical vapor infiltration method is used to deposit pyrolytic carbon at 1000°C, and the density is obtained after deposition for 200 hours. 1.45g / cm 3 Low-density C / C material...

Embodiment 3

[0070] (1) Firstly, the PAN type T700 (12K) carbon fiber produced by Japan Toray Company (Toray) is used to make tire mesh and no-weft fabric, and the single-layer 0° no-weft fabric, net tire layer, 90° no-weft fabric, The mesh layers are superimposed in sequence, and then the density is 0.1g / cm by the method of relay needle punching. 3 carbon fiber prefabricated body;

[0071] (2) Under an argon protective atmosphere, the preform is subjected to a high-temperature heat treatment before 1500 ° C, the whole time is 10 hours, and the pressure is slightly positive pressure (that is, slightly exceeding the zero scale of the vacuum pressure gauge);

[0072] (3) Using methane as the carbon source gas, nitrogen as the diluent gas, and the volume ratio of methane and nitrogen as 1:1, using the isothermal chemical vapor infiltration method to deposit pyrolytic carbon on the preform at 900 ° C, and deposit it after 120 hours. The density is 1.0g / cm 3 Low-density C / C material;

[0073...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com