Friction material of brake sheet for rail transit vehicle brake system, and preparation method and application of friction material

A technology for rail transit vehicles and braking systems is applied in the field of friction materials and preparation of brake pads of rail transit vehicles braking systems, and can solve the problems of increased wear, large fluctuations in friction coefficients, attenuation of friction coefficients of brake pads, and the like. , to achieve the effect of low wear rate, low cost and stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to the weight ratio of the following components: 50 parts of Cu, 11 parts of Fe, 7 parts of Sn, 3 parts of Ni, 2 parts of Mn, 3 parts of Cr, 12 parts of C (flake graphite), 6 parts of SiC and 6 parts of Mo are mixed and prepared Mixture. A V-shaped mixer is used for mixing, and in order to avoid segregation, 20-40ml of ethanol is added to each kilogram of the mixture, and the mixing time is 2 hours. Use a powder metallurgy hydraulic press to press the mixture according to the shape of the brake pad friction block mold, the pressing pressure is 25Mpa, and the pressing time is 1min. Then put the pressed mixture into a bell furnace for sintering, the sintering pressure is 5Mpa, the sintering temperature is 880°C, the sintering time is 6h, and ammonia gas is used as the protective atmosphere.

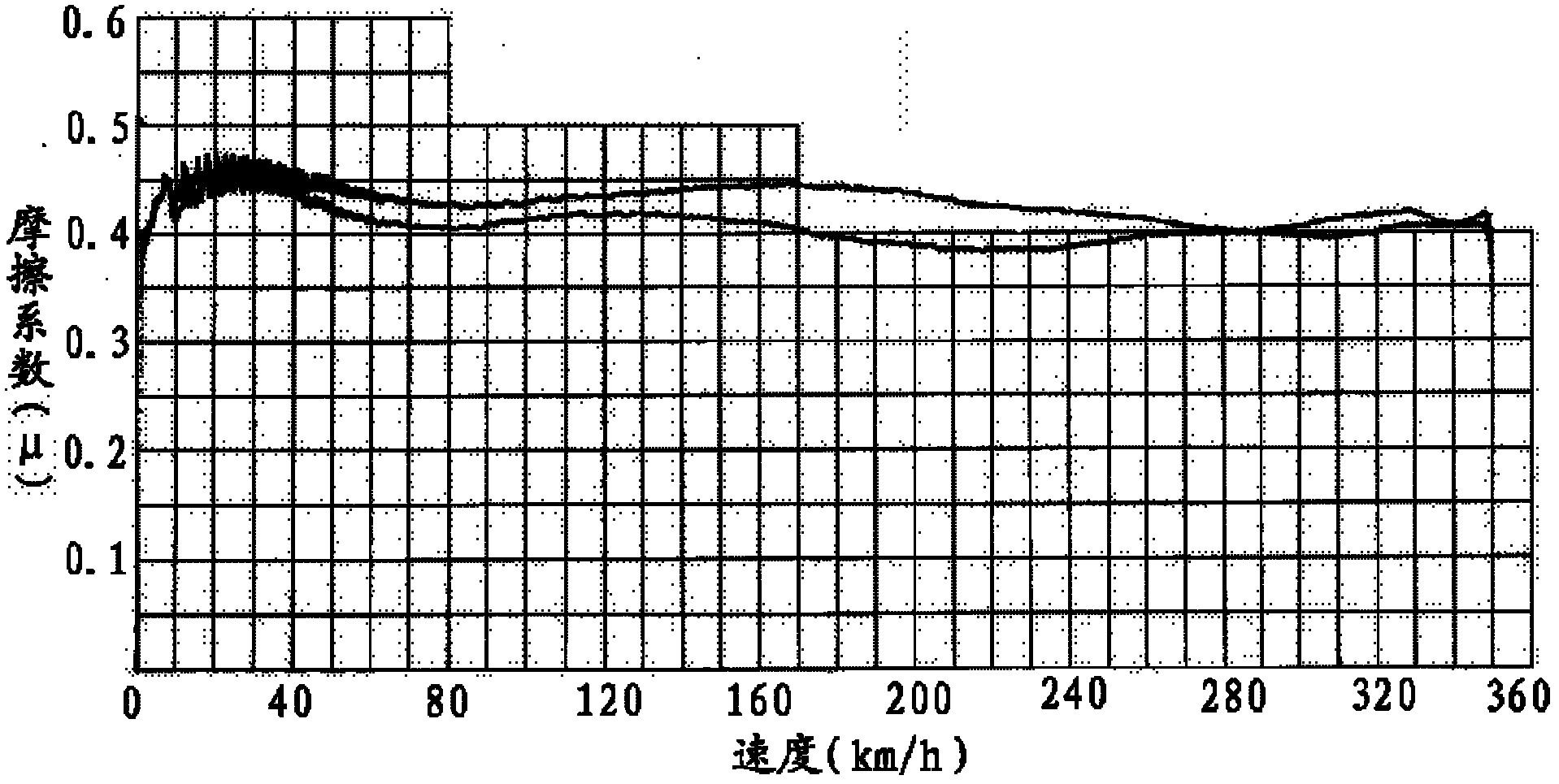

[0043] A 1:1 braking power test bench is used to test the friction material of the above-mentioned brake pads used in the braking system of rail transit vehicles. At a spe...

Embodiment 2

[0045] According to the weight ratio of the following components: 55 parts of Cu, 8 parts of Fe, 8 parts of Sn, 4 parts of Ni, 2 parts of Mn, 4 parts of Cr, 13 parts of C (flake graphite), 3 parts of SiC and 3 parts of Mo are mixed and prepared Mixture. A V-shaped mixer is used for mixing, and in order to avoid segregation, ethanol is added, and the mixing time is 1 h. Use a powder metallurgy hydraulic press to press the mixture according to the shape of the brake pad friction block mold, the pressing pressure is 20Mpa, and the pressing time is 1min. Then put the pressed mixture into a bell furnace for sintering, the sintering pressure is 3Mpa, the sintering temperature is 860°C, the sintering time is 8h, and ammonia gas is used as the protective atmosphere.

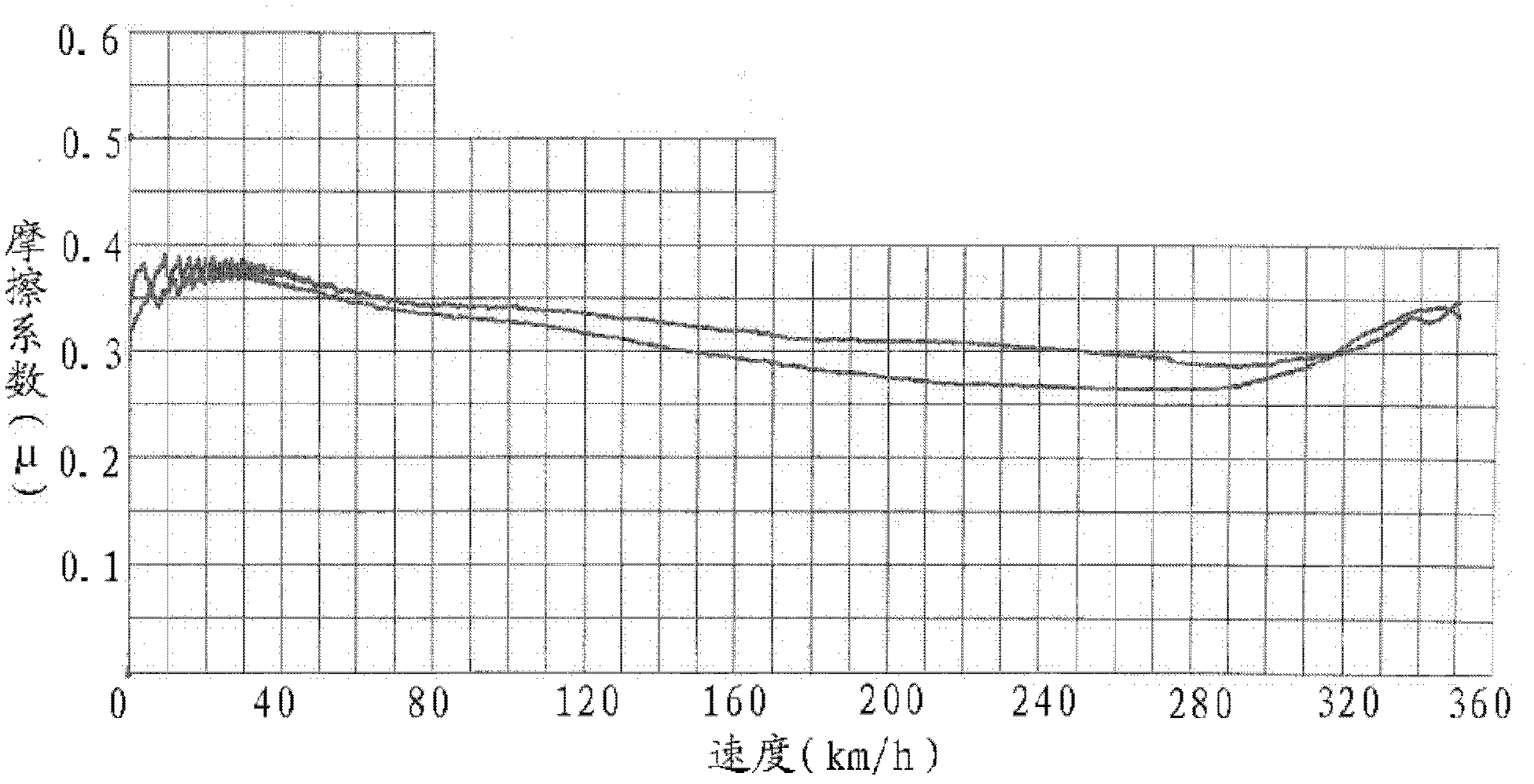

[0046] A 1:1 braking power test bench was used to test the friction material of the above-mentioned brake pads used in the braking system of rail transit vehicles. At a speed equivalent to 350km / h, the friction coeffici...

Embodiment 3

[0048] According to the weight ratio of the following components: 53 parts of Cu, 12 parts of Fe, 8 parts of Sn, 4 parts of Ni, 2 parts of Mn, 4 parts of Cr, 10 parts of C (flake graphite), 4 parts of SiC and 5 parts of Mo are mixed and prepared Mixture. A V-shaped mixer is used for mixing, and in order to avoid segregation, ethanol is added, and the mixing time is 1.5h. Press the mixture according to the shape of the friction block mold of the brake pad, the pressing pressure is 15Mpa, and the pressing time is 1min. Then put the pressed mixture into a bell furnace for sintering, the sintering pressure is 3Mpa, the sintering temperature is 870°C, the sintering time is 10h, and ammonia gas is used as the protective atmosphere.

[0049] A 1:1 braking power test bench was used to test the above-mentioned friction material for the brake pads used in the braking system of rail transit vehicles. At a speed equivalent to 350km / h, the friction coefficient was 0.36, and the wear rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com