Automobile steel-made synchronizer ring gear carbon fiber friction material and use

A synchronizer gear ring and friction material technology, which is applied in the field of automobile friction materials, can solve the problems of insignificant cost reduction, high molybdenum price, and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

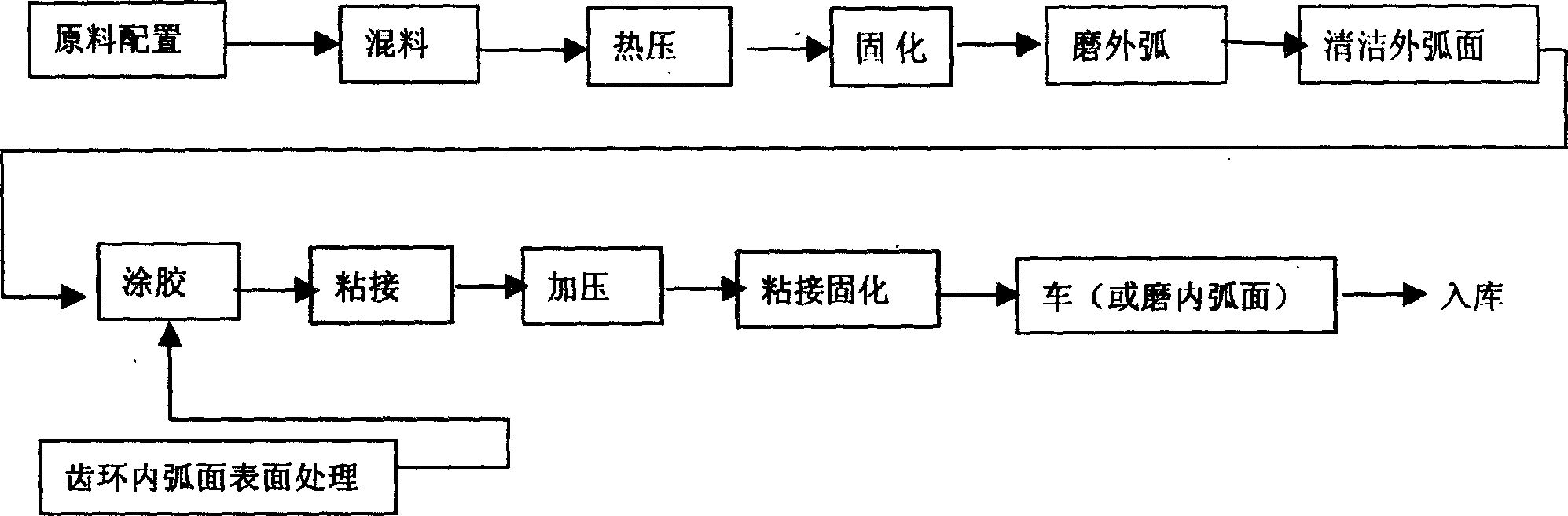

[0042] Preparation of carbon fiber friction material for automobile steel synchronizer gear ring: Weigh the raw materials according to the raw material ratio in Table 1, mix them evenly with a mixer, and then hot press them into pieces with a hot press and a hot pressing die. The hot pressing condition is pressure 15MPa, temperature 160°C, tablet pressing time is determined according to the thickness of the friction plate, the pressing time is 1.5 to 2 minutes per 1mm thickness, the operating process is 15MPa pressure at 160°C for 40 seconds, 0MPa exhaust for 20 seconds, and then Press at 15MPa for 40 seconds, exhaust at 0MPa for 20 seconds, press at 15MPa for 4 minutes, and release the mold at 0MPa to obtain a sample of the pressed friction sheet; heat and cure the pressed sheet. The curing process is: from room temperature to 100°C for 1 hour, and then Raise the temperature to 120°C for 1 hour, then raise the temperature to 140°C for 1 hour, heat at 140°C for 2 hours, then ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com