Preparation method of multi-element nano composite material suitable for lean oil working condition

A technology of nano-composite materials and working conditions, applied in the field of composite materials, can solve the problems of self-lubricating composite materials, etc., and achieve the effects of reducing friction coefficient, improving friction and wear resistance, and inhibiting direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

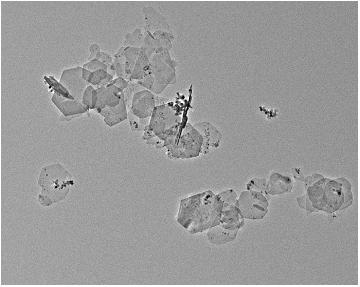

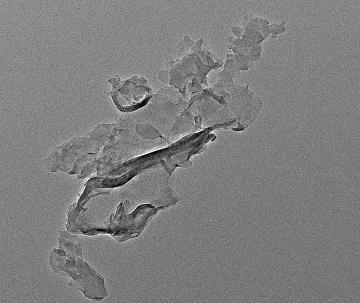

[0026] Example 1 A method for preparing a multi-component nanocomposite suitable for oil-lean conditions: first prepare hydrotalcite sheets and carbon nitride nanosheets; Carbonized carbon nanosheets are added to 99.8% epoxy resin, and the vacuum degree is -1×10 5 Stir and mix for 15 minutes at Pa and 1000r / min, then add curing agent, continue mixing at 3000r / min for 5 minutes to obtain the mixed liquid; finally, pour the mixed liquid into the mold and cure at 120°C for 4 hours to obtain Magnesium-aluminum hydrotalcite / carbon nitride modified epoxy resin-based composites.

[0027] Wherein: hydrotalcite nanosheets (LDHs) are prepared according to the following steps:

[0028] ⑴Magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O) dispersed in deionized water to obtain a solution A with a concentration of 0.01mol / L;

[0029] ⑵ Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) dispersed in deionized water to obtain a solution B with a concentration of 0.01mol / L;

Embodiment 2

[0034]Example 2 A method for preparing a multi-component nanocomposite suitable for oil-lean conditions: first prepare hydrotalcite sheets and carbon nitride nanosheets; Carbonized carbon nanosheets are added to 80% epoxy resin, and the vacuum degree is -1×10 5 Stir and mix for 15 minutes at Pa, speed of 1000r / min, then add curing agent, and continue mixing for 5 minutes at a speed of 3000r / min to obtain the mixed liquid; finally, pour the mixed liquid into the mold and cure at 120°C for 8 hours to obtain Magnesium-aluminum hydrotalcite / carbon nitride modified epoxy resin-based composites.

[0035] Wherein: hydrotalcite nanosheets (LDHs), carbon nitride nanosheets are the same as in Example 1.

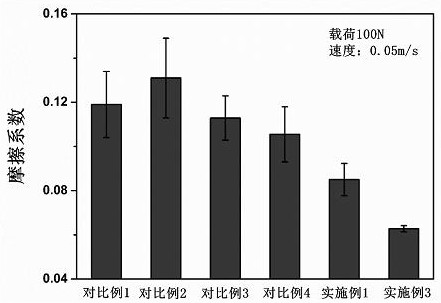

[0036] Tribological experiments were carried out on the above-mentioned composite materials, and the surface of the metal ring was pre-wetted with 5 μL PAO4 base oil with a microliter syringe to investigate the tribological properties of the epoxy resin-based composite materials under...

Embodiment 3

[0037] Example 3 A method for preparing a multi-component nanocomposite suitable for oil-poor working conditions: first prepare hydrotalcite sheets and carbon nitride nanosheets; then, by mass fraction, 2% hydrotalcite sheets and 8% nitrogen Carbonized carbon nanosheets are added to 94% epoxy resin, and the vacuum degree is -1×10 5 Stir and mix for 15 minutes at Pa, speed of 1000r / min, then add curing agent, and continue mixing for 5 minutes at a speed of 3000r / min to obtain the mixed liquid; finally, pour the mixed liquid into the mold and cure at 120°C for 5 hours to obtain Cobalt-zinc hydrotalcite / carbon nitride modified epoxy resin-based composites.

[0038] Wherein: hydrotalcite nanosheets (LDHs) are prepared according to the following steps:

[0039] ⑴ Zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) dispersed in deionized water to obtain a solution A with a concentration of 0.01mol / L;

[0040] (2) Cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) dispersed in deionized water to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com