Self-lubricating bionic texture guide rail device for automobile production line switching platform

An automobile production line, bionic texture technology, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of the surface of the guide rail cannot be repaired and used, increase the production cost, etc., achieve good self-lubricating effect, reduce working energy consumption, The effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

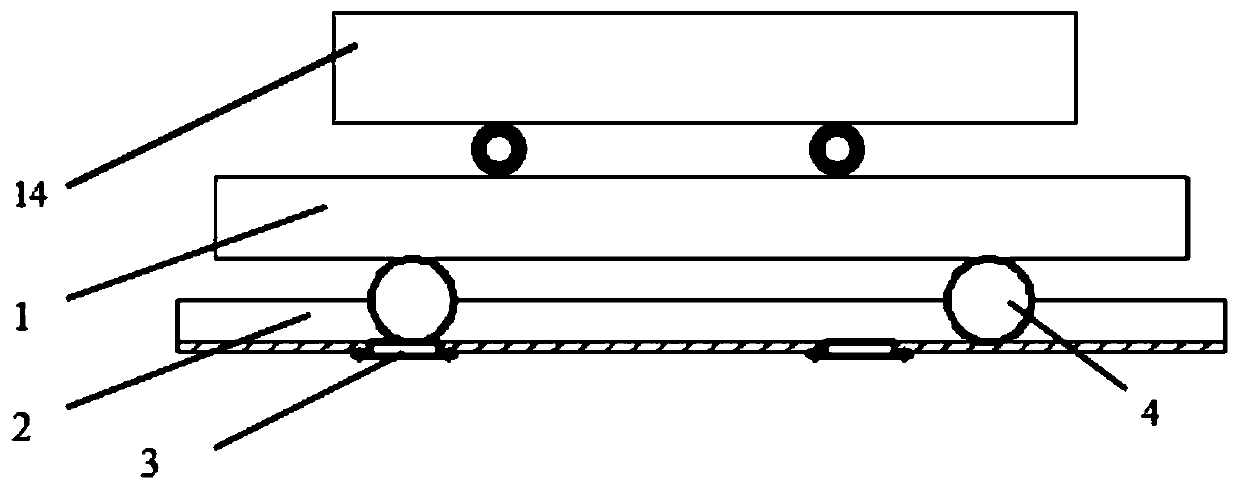

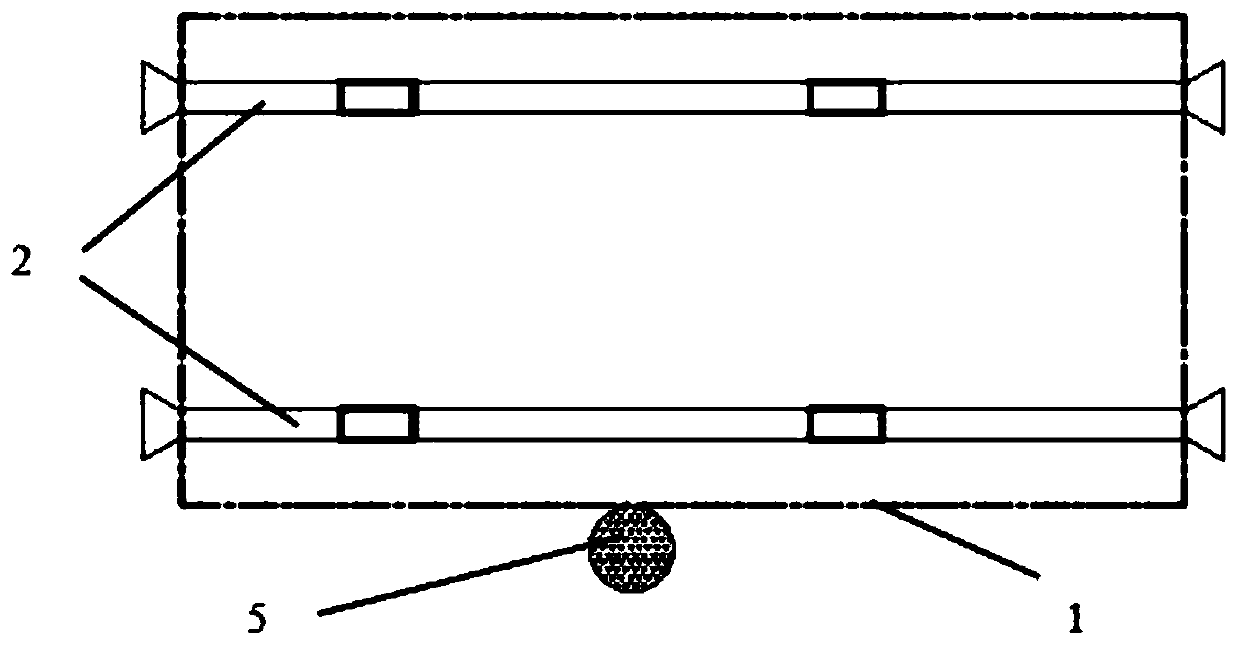

[0030] Such as figure 1 , figure 2 As shown, the self-lubricating bionic texture guide rail device for the transfer platform of the automobile production line of the present invention includes a transfer platform 1, at least two supporting guide rails 2, several self-lubricating guide rails 3, and several self-lubricating guide rails 3 carried by the transfer platform. Supporting rollers 4; the supporting guide rails 2 are arranged in parallel, the lower part of the supporting rollers 4 is located in the supporting guide rails 2, and each supporting guide rail 2 is provided with at least two left and right supporting rollers 4, and the self-lubricating guide rail 3 is embedded in the bottom of the supporting guide rails 2 , its upper plane is flush with the lowest point of the support roller 4, and at least two self-lubricating guide rails 3 on the left and right are arranged in each support guide rail 2.

[0031] When the transfer platform 1 works, the car 14 is placed on t...

Embodiment 2

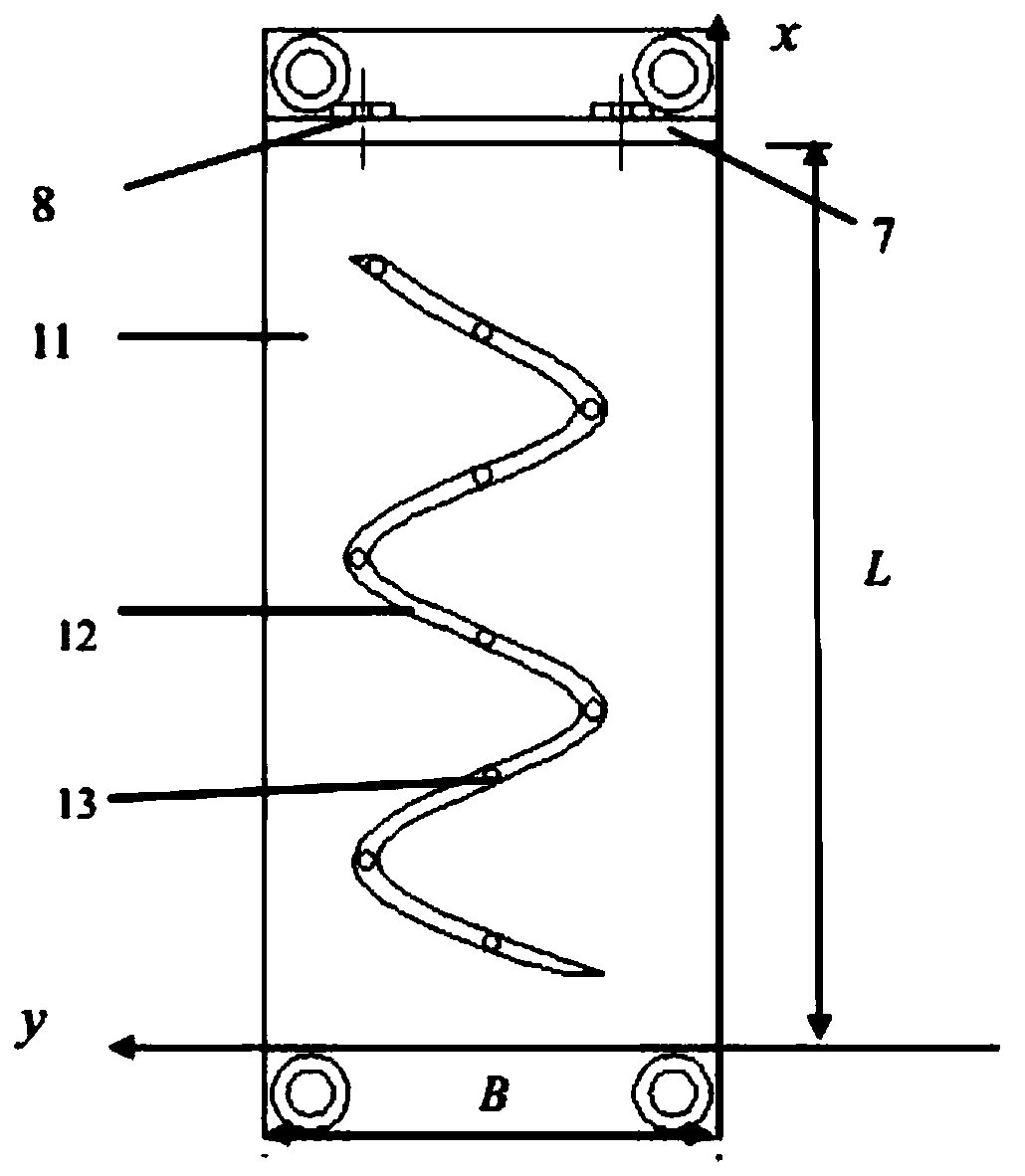

[0033] Such as image 3 , Figure 4 As shown, in the self-lubricating bionic texture guide rail device of the present invention: the self-lubricating guide rail 3 includes a guide rail body, a guide rail end cover 7, and an end cover screw 8; There are several grooves 12 on the top of the body, and several microholes 13 are opened in the middle of each groove 12. The microholes 13 communicate with the cavity of the guide rail. The end cover 7 of the guide rail is installed on the end surface of the guide rail body through the end cover screw 8. , the rail body is fastened under the supporting rail 2 by screws at both ends.

[0034] Such as Figure 5 As shown, as an improvement of the present invention, the self-lubricating guide rail 3 in the self-lubricating bionic texture guide rail device of the present invention also includes a backing plate 9 and several adjusting bolts 10, and the backing plate 9 is arranged in the space of the guide rail body. In the cavity, the adju...

Embodiment 3

[0037] Such as image 3 , Figure 4 As shown, the present invention divides the self-lubricating guide rail 3 into single-line type and multi-line type according to the number of grooves on the guide rail body: when the self-lubricating guide rail is a single-line type guide rail, the guide rail body is a single-line type guide rail body 11, and the single-line type A groove 12 is provided on the top of the guide rail body 11 along its length direction, and a series of microholes 13 are arranged in the center of the groove; when the self-lubricating guide rail is a multi-line guide rail, that is, the guide rail body is a multi-line guide rail body 6, At least two grooves 12 are arranged on the upper surface of the multi-line guide rail body 6 along its length direction, each groove has the same shape and equal spacing, and a series of microholes 13 are arranged in the center of the grooves. The use of multi-line or single-line self-lubricating guide rails is determined accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com