Composite friction material, brake lining and brake lining production method

A composite friction material and friction material technology, applied in friction linings, chemical instruments and methods, other chemical processes, etc., can solve the problems of waste of high-quality raw materials and increase material costs, and achieve cost reduction, low requirements, and excellent friction and wear. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

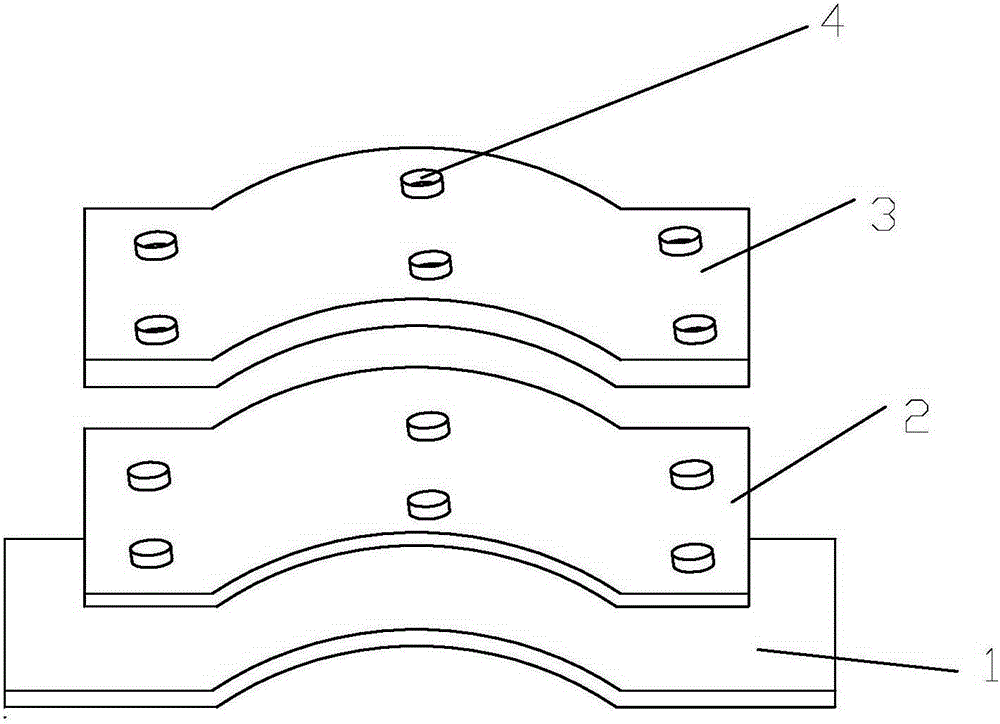

[0038] The composite friction material in this embodiment includes a composite organic friction material layer 3 and a powder metallurgy friction material layer 2 .

[0039] The powder metallurgy friction material layer 2 accounts for 75-80% of the entire thickness.

[0040] The organic friction material layer 3 and the powder metallurgy material layer are connected by means of gluing and hot pressing.

[0041] The powder metallurgy friction material layer 2 has several embedding holes 4 , and a part of the organic friction material layer 3 is embedded in the embedding holes 4 .

Embodiment 2

[0043] The brake pad made of the above-mentioned composite friction material in this embodiment also includes a steel backing plate 1 , and the steel backing plate 1 is connected to the organic friction material layer 3 by means of gluing and hot pressing.

Embodiment 3

[0045] The present embodiment is the manufacture method of above-mentioned brake pad, comprises the following steps:

[0046] 1) The step of preparing powder metallurgy friction material layer 2;

[0047] 2) The surface of the steel back plate 1 is degreased, derusted, and glued, and then placed in a mold, and an organic friction material mixture is added;

[0048] 3) The powder metallurgy friction material layer 2 in step 1) is coated with glue, placed on the mixture in step 2), and hot-pressed to obtain a brake pad blank.

[0049] It also includes the steps of heat treating and machining the brake pad blank.

[0050] In step 1), several embedding holes 4 are drilled on the prepared powder metallurgy friction material layer 2 .

[0051] The steps for preparing powder metallurgy friction material layer 2 are:

[0052] Ingredients mixing: Weigh the raw materials with the following components and mass percentages: 70% iron powder, 5% calcined petroleum coke powder, 2% nickel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com