TiMoCN gradient composite coated tool and preparation method thereof

A composite coating and cutting tool technology, which is applied in the field of TiMoCN gradient composite coating cutting tools and its preparation, to achieve the effects of increasing hardness and strength, improving hardness and wear resistance, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

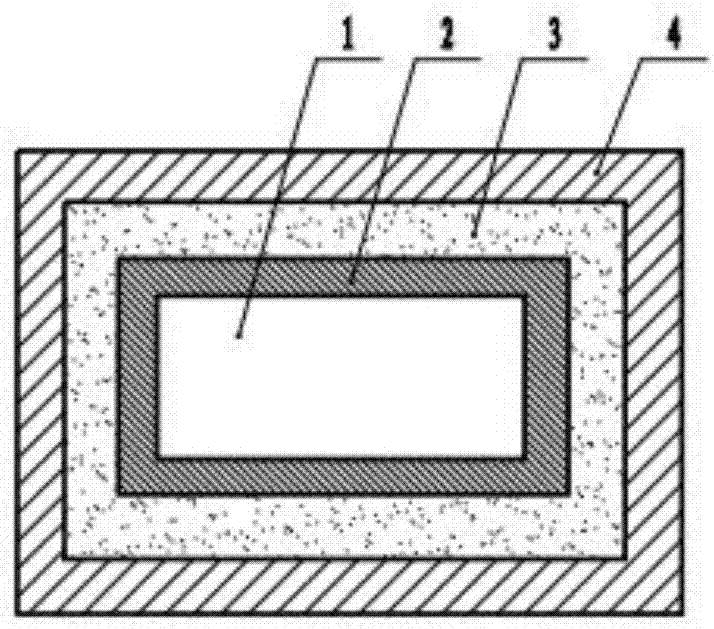

[0021] The TiMoCN gradient composite coating tool and its preparation method of the present invention, the tool is a common milling blade, its base material is: cemented carbide M05, the coated tool is the tool base, Ti transition layer, TiMoC transition from the inside to the outside layer and TiMoCN gradient composite coating with gradient gradient of nitrogen content. The deposition method adopts the composite coating method of intermediate frequency magnetron sputtering and arc plating. During deposition, two intermediate frequency magnetron sputtering TiMoC composite targets and two arc plating Ti targets are used. First, arc plating is used to deposit the Ti transition layer, and then intermediate frequency magnetic The controlled sputtering method deposits the TiMoC transition layer and the TiMoCN gradient composite coating with a gradient nitrogen content. The specific steps are as follows:

[0022] (1) Pretreatment: Polish the surface of the tool base to remove impuri...

Embodiment 2

[0029] The TiMoCN gradient composite coating tool and its preparation method of the present invention, the tool is a circumferential milling cutter, the tool matrix material is: high-speed steel W18Cr4V, the coated tool is sequentially from the inside to the outside of the tool matrix, Ti transition layer, TiMoC transition layer and Gradient TiMoCN composite coating with gradient nitrogen content. The deposition method adopts the composite coating method of intermediate frequency magnetron sputtering and arc plating. During deposition, two intermediate frequency magnetron sputtering TiMoC composite targets and two arc plating Ti targets are used. First, the Ti transition layer is deposited by arc plating, and then the TiMoC transition layer and the TiMoCN gradient composite coating with a gradient nitrogen content are deposited by the intermediate frequency magnetron sputtering method. The specific steps are as follows:

[0030] (1) Pretreatment: Polish the surface of the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com