Method for strengthening composite coating by using nano silicon dioxide sol and rare-earth

A nano-silica and composite coating technology, applied in liquid chemical plating, coating, metal material coating technology and other directions, can solve the problems of easy agglomeration and poor effect of nanoparticles, and achieve uniform particle distribution, low cost, The effect of increasing the hardness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

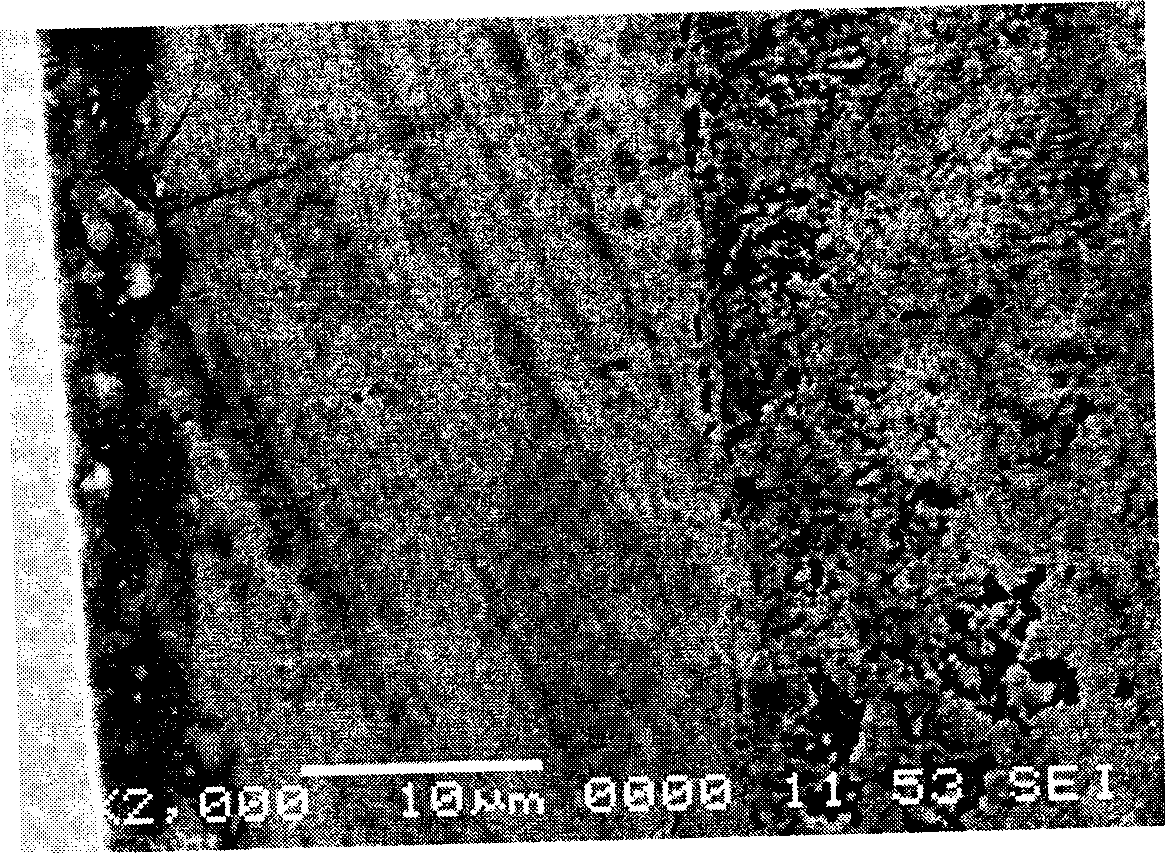

Image

Examples

Embodiment 1

[0024] 1. Preparation of chemical composite plating solution,

[0025] The content of each component in each liter of plating solution is: nickel sulfate 30g / L, sodium hypophosphite 35g / L, citric acid 25g / L, sodium acetate 20g / L, potassium iodide 60mg / L, sodium dodecylbenzenesulfonate 3mg / L, cerium sulfate 2mg / L, SiO 2 Sol 10ml / L, add deionized water to prepare the plating solution, adjust the pH value of the plating solution to 4.5 with sodium hydroxide;

[0026] 2. Heat the above bath to 75°C;

[0027] 3. Put the carbon steel sample into the alkaline degreasing bath (Na 2 CO 3 =35g / L, Na 3 PO 4 12H 2 (O=15g / L, NaOH=7.5g / L) for chemical degreasing, temperature 70°C, take it out after 10 minutes, remove and rinse with deionized water;

[0028] 4. Put the degreased sample into 5% dilute sulfuric acid solution for pickling for 1 min, then rinse with deionized water;

[0029] 5. Put the sample after pickling into the plating solution to ensure that the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com