Environment-friendly water-based glass baking lacquer

A glass baking paint, environmentally friendly technology, applied in the field of baking paint, can solve the problems of short service life, low hardness, poor wear resistance, etc., to achieve the effect of improving service life, high hardness value, high dry and wet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

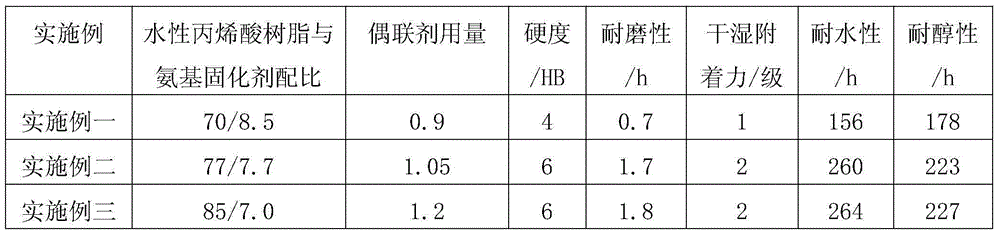

Embodiment 1

[0017] An environmentally friendly water-based glass baking varnish, the baking varnish is composed of the following components in parts by weight: 90 parts of water, 8.5 parts of amino curing agent, 70 parts of water-based acrylic resin, 0.35 parts of defoaming agent, 0.25 parts of wetting agent, and 0.2 parts of leveling agent 0.9 parts, 0.9 parts of coupling agent, 0.15 parts of anti-scratch agent and 0.5 parts of pH regulator.

[0018] The amino curing agent is an amino resin curing agent, and the amino resin curing agent plays the role of quickly curing the baking varnish.

[0019] The coupling agent is a siloxane coupling agent, and the siloxane coupling agent reacts with the key curing agent to bond or form entanglements, so as to improve adhesion and reduce the penetration of water or alcohol substances into the substrate Function, increasing the water resistance and alcohol resistance of the baking paint.

[0020] The pH regulator is hydrogen chloride solution.

[0...

Embodiment 2

[0026] An environment-friendly water-based glass baking varnish, the baking varnish is composed of the following components in parts by weight: 105 parts of water, 7.7 parts of amino curing agent, 77 parts of water-based acrylic resin, 0.57 parts of defoaming agent, 0.3 parts of wetting agent, and 0.25 parts of leveling agent 1.05 parts of coupling agent, 0.2 parts of anti-scratch agent and 0.6 parts of pH regulator.

[0027] The amino curing agent is an amino resin curing agent, and the amino resin curing agent plays the role of quickly curing the baking varnish.

[0028] The coupling agent is a siloxane coupling agent, and the siloxane coupling agent reacts with the key curing agent to bond or form entanglements, so as to improve adhesion and reduce the penetration of water or alcohol substances into the substrate Function, increasing the water resistance and alcohol resistance of the baking paint.

[0029] The pH regulator is hydrogen chloride solution.

[0030] A prepara...

Embodiment 3

[0035] An environment-friendly water-based glass baking varnish, the baking varnish is composed of the following components by weight: 120 parts of water, 7 parts of amino curing agent, 85 parts of water-based acrylic resin, 0.8 parts of defoaming agent, 0.35 parts of wetting agent, and 0.3 parts of leveling agent parts, 1.2 parts of coupling agent, 0.25 parts of anti-scratch agent and 0.7 parts of pH regulator.

[0036] The amino curing agent is an amino resin curing agent, and the amino resin curing agent plays the role of quickly curing the baking varnish.

[0037] The coupling agent is a siloxane coupling agent, and the siloxane coupling agent reacts with the key curing agent to bond or form entanglements, so as to improve adhesion and reduce the penetration of water or alcohol substances into the substrate Function, increasing the water resistance and alcohol resistance of the baking paint.

[0038] The pH regulator is hydrogen chloride solution.

[0039] A preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com