Hard tinned original plate with thin specification and manufacture method thereof

A thin-gauge, original plate technology, applied in the field of iron and steel smelting materials, can solve the problems of difficulty in meeting the precision requirements of high-quality tin-plated plates, insufficient rolling technical capabilities, and deviation of stamping performance, and achieves elimination of through-board failures, small thickness, and stamping. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below by way of examples.

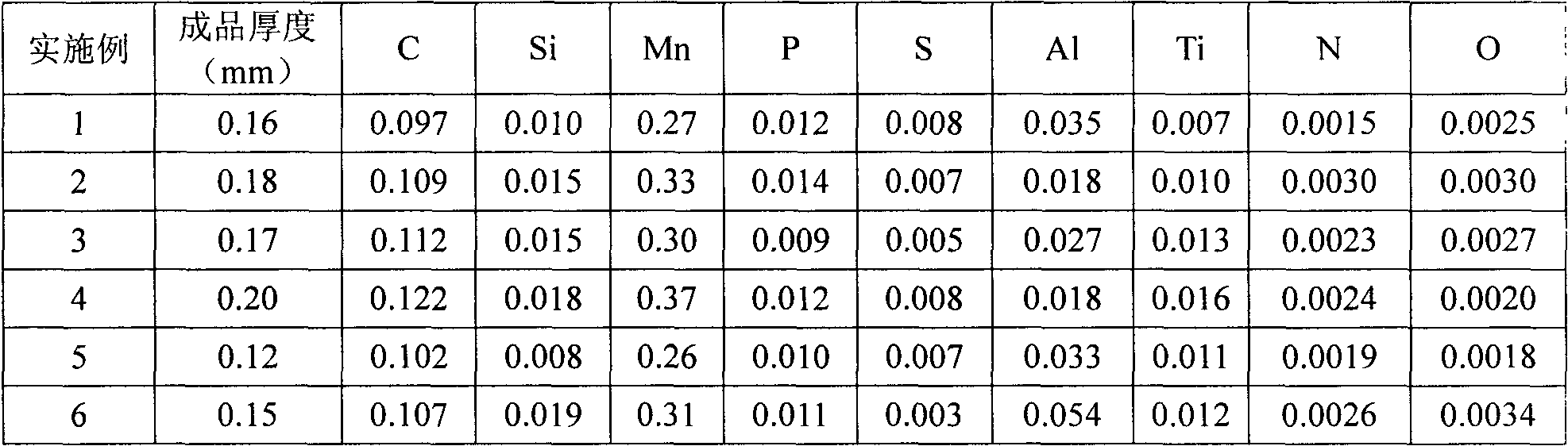

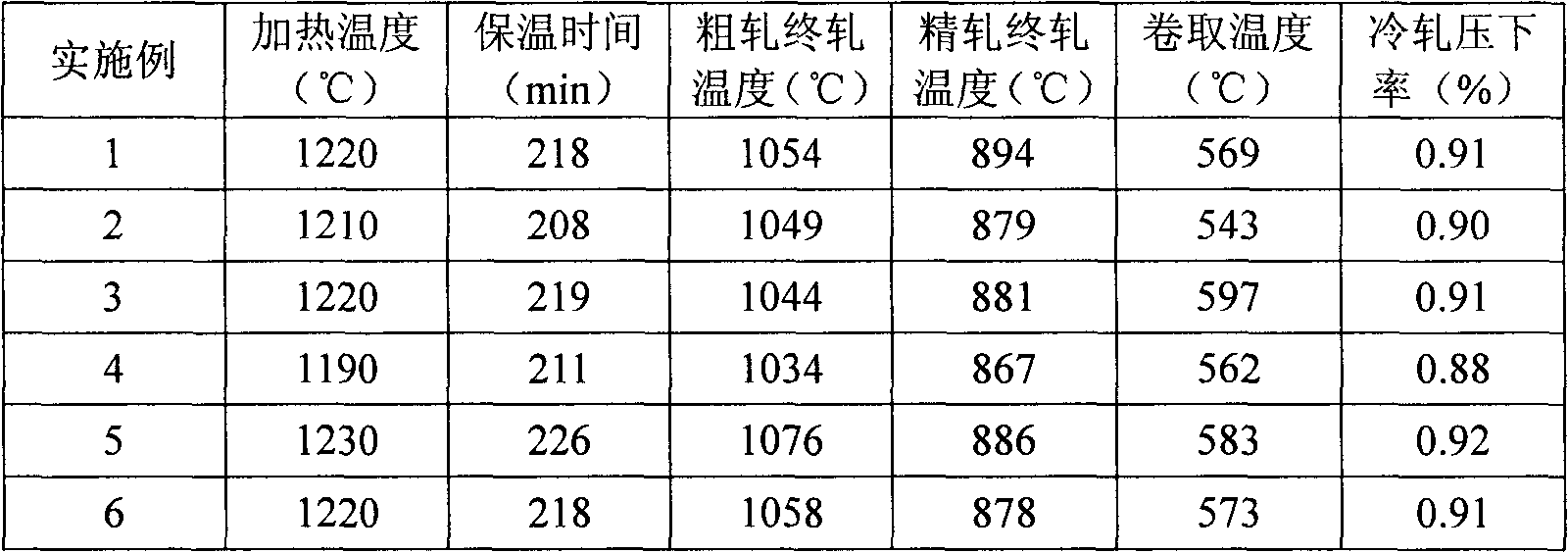

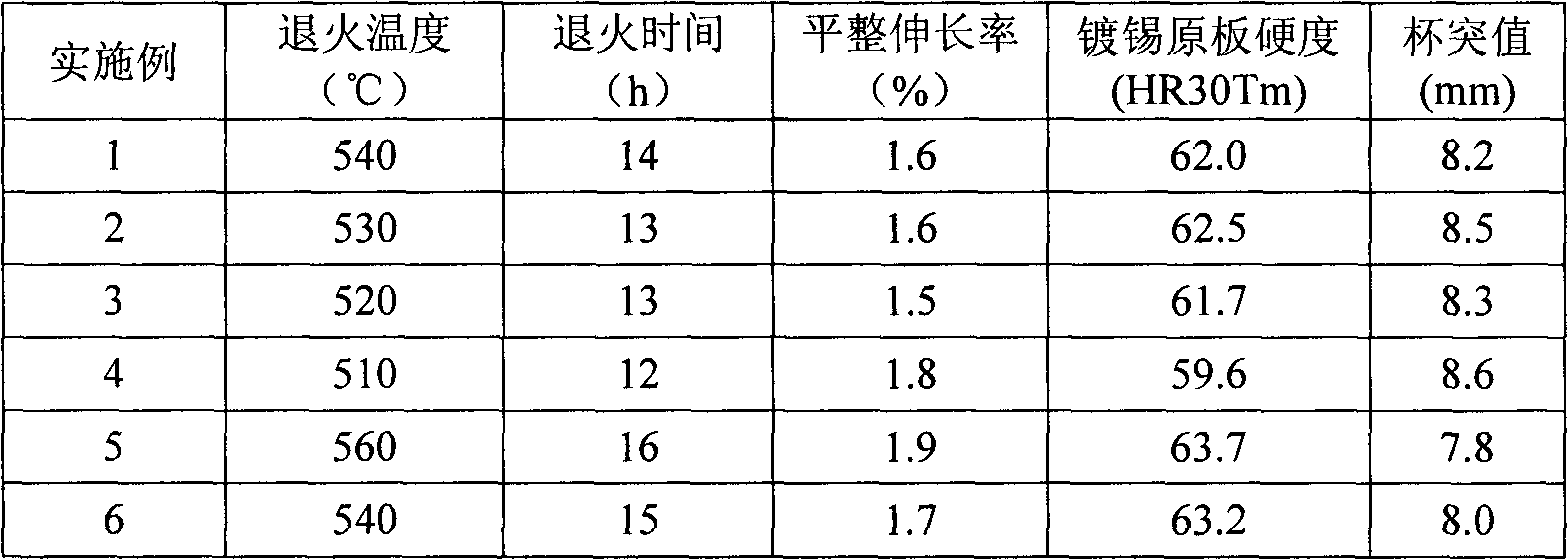

[0035] The chemical composition of the molten steel of the embodiment of the present invention is shown in Table 1 (the balance is Fe and unavoidable impurities). After the continuous casting slab is reheated and kept warm, it is coiled after rough rolling, finish rolling and laminar cooling. After cooling at room temperature, it is pickled and cold rolled. The specific process parameters are shown in Table 2. The cold-rolled steel strip is annealed and leveled to obtain a tin-plated original plate. The corresponding parameters are shown in Table 3.

[0036] Table 1 The chemical melting composition (Wt%) of the original plate of the embodiment of the present invention

[0037]

[0038] The main technological parameter of table 2 embodiment of the present invention

[0039]

[0040] The annealing process parameter and performance of the embodiment of the present invention of table 3

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com