All-weather conical sand maker and self-adjustment method

A technology of conical sand making machine and adjustment method, which is applied in the resulting field, and can solve problems such as complete loss of strength, inability to achieve effective improvement of local hardness, and fracture of the copper sleeve of the main shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

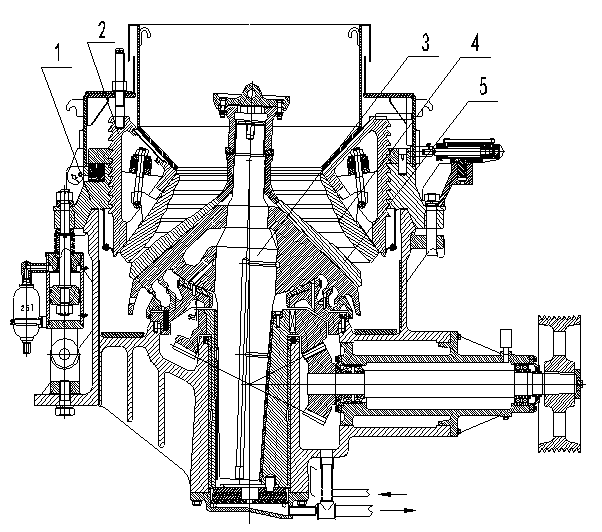

[0037] Embodiment 1: with reference to attached Figure 1-11 . An all-weather cone sand making machine, comprising a cone sand making machine, when the adjusting screw sleeve 2 and the upper casing 1 in the cone sand making machine are screwed clockwise, the rotation direction of the main shaft 3 in the cone sand making machine is reverse Turn clockwise; on the contrary, when the adjusting screw sleeve 2 in the cone sand making machine and the upper casing 1 are screwed counterclockwise, the rotation direction of the main shaft 3 in the cone sand making machine is clockwise.

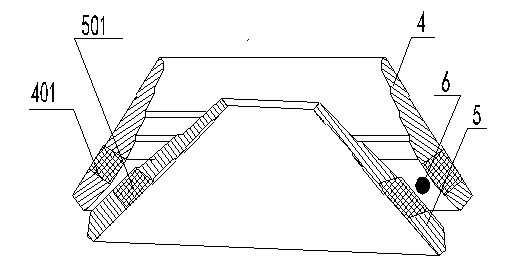

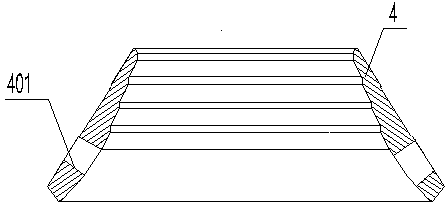

[0038] The sand-making and rolling port 6 in the cone sand making machine is composed of a high-chromium cast iron anti-wear movable set sand-making rolling wall 501 and a high-chromium cast iron anti-wear fixed set sand-making rolling wall 401. The high-chromium cast iron anti-wear dynamic The hardness of the set sand rolling wall 501 and the high chromium cast iron wear-resistant set sand rolling wall...

Embodiment 2

[0041] Example 2: On the basis of Example 1, the high chromium cast iron anti-wear moving sleeve 5 and the high chromium cast iron anti-wear fixed sleeve 4 are removed from the high chromium cast iron anti-wear moving sleeve for sand rolling wall 501 and high chromium cast iron anti-wear Except for the set sand making rolling wall 401, the remaining 5 walls of the high chromium cast iron anti-wear moving sleeve and the 4 walls of the high chromium cast iron anti-wear fixed sleeve are formed by heat preservation and delayed cooling.

Embodiment 3

[0042]Example 3: On the basis of Example 1, a non-stop method for an all-weather conical sand making machine, (1) When the adjusting screw sleeve 2 and the upper casing 1 in the conical sand making machine are screwed clockwise, the conical sand making machine The rotation direction of the main shaft 3 in the sand machine is counterclockwise. When the cone sand making machine is used to make sand, the sand and stones located in the sand making chamber of the anti-wear moving sleeve 5 and the anti-wear fixed sleeve 4 will be generated due to the large amount of feed during the sand making process. When clogging, due to the clockwise connection between the adjusting screw sleeve 2 and the upper casing 1 in the cone sand making machine, the anti-wear fixed sleeve 4 is fixed on the adjusting screw sleeve 2, and the main shaft 3 in the cone sand making machine drives the anti-friction movable sleeve The rotation direction of 5 is counterclockwise, so turning the anti-friction moving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com