Hexabasic high-entropy alloy and preparation method thereof

A high-entropy alloy, atomic percentage technology, applied in the field of metal materials and their preparation, can solve problems such as poor plasticity, and achieve the effect of simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

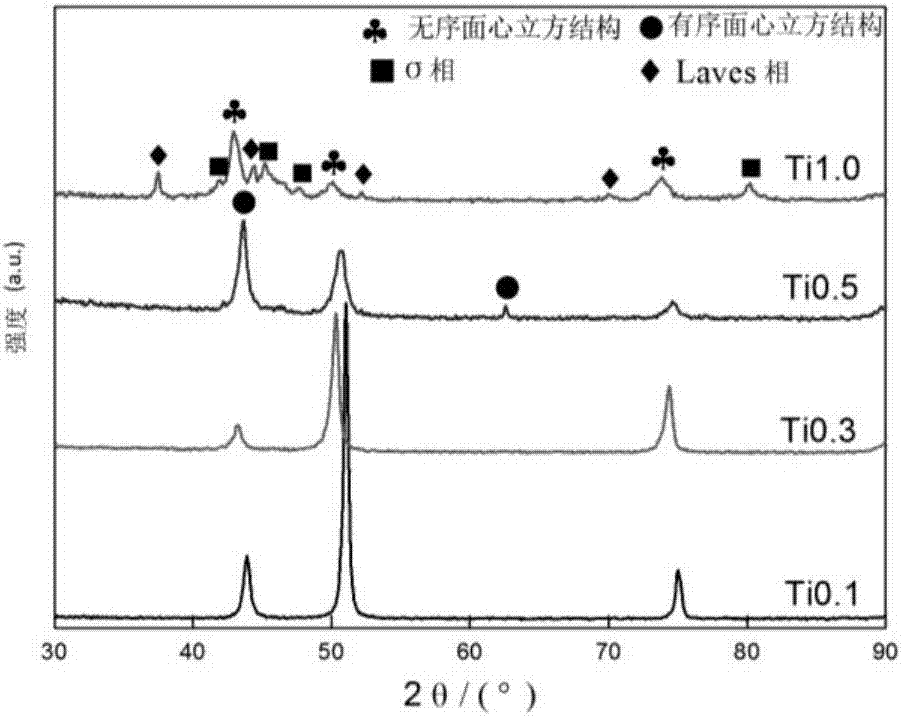

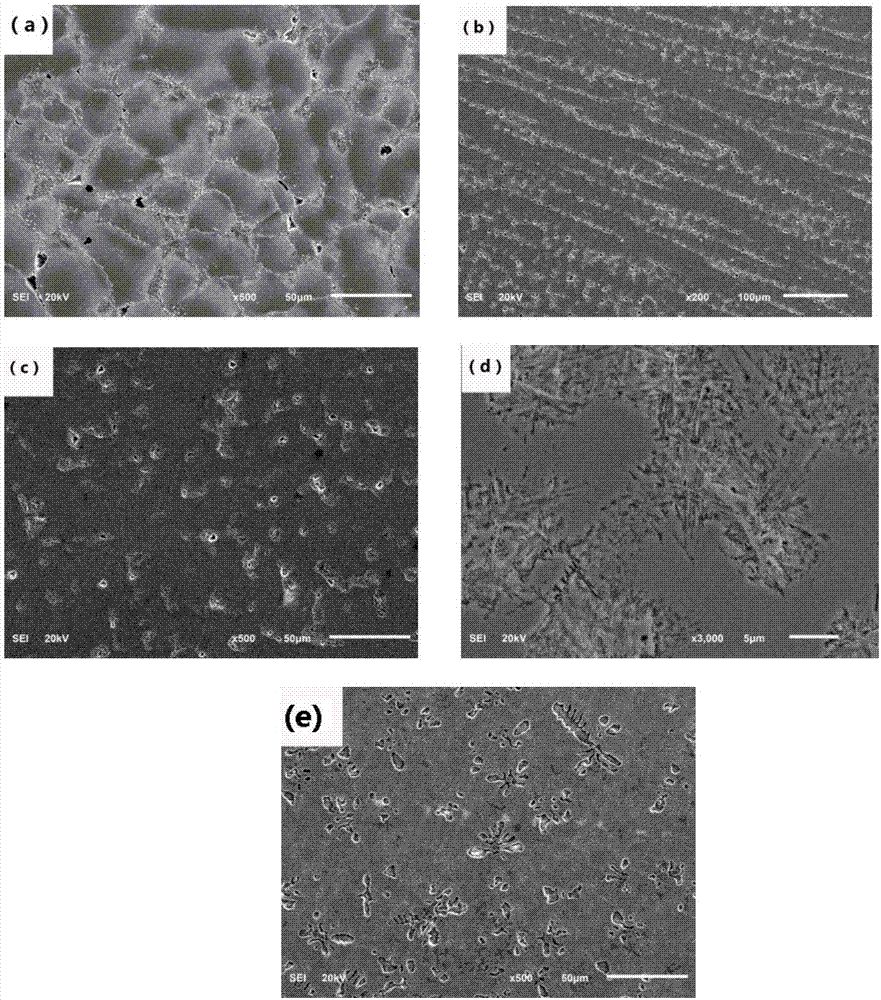

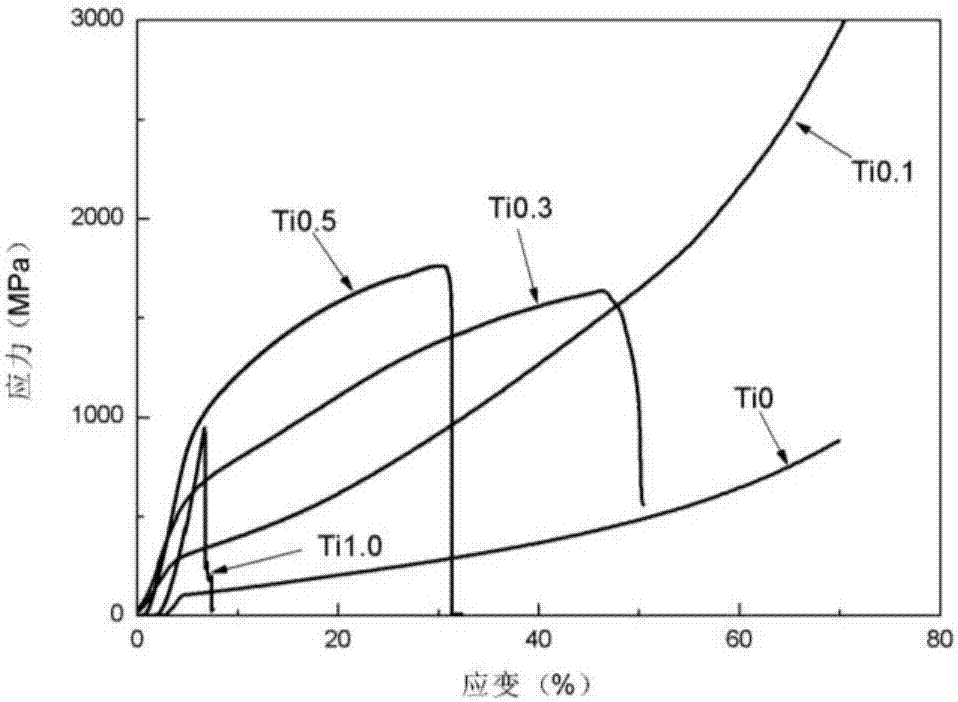

[0031] A six-membered CoCrCu 0.5 FeNiTi high-entropy alloy material, wherein the atomic percentage range of the material composition is Co: 18.18-22.22at%, Cr: 18.18-22.22at%, Cu: 9.1-11.12at%, Fe: 18.18-22.22at%, Ni: 18.18 ~ 22.22at%, Ti: 2.17~18.18at%.

[0032] A kind of CoCrCu described in this embodiment 0.5 The preparation method of FeNiTi system high-entropy alloy, concrete steps are as follows:

[0033] (1) Ingredients: High-purity metal raw materials (≥99.95%) are accurately weighed and proportioned according to mass percentages for use in smelting alloys. The alloy composition is shown in Table 1.

[0034] Table 1: CoCrCu 0.5 FeNiTi x (x=0,0.1,0.3,0.5,1.0) Nominal composition of high entropy alloy (at%)

[0035]

[0036] (2) Smelting of high-entropy alloys: the present invention adopts WK type non-consumable vacuum electric arc furnace, puts the weighed elemental raw material into the water-cooled copper mold smelting pool in the WK type non-consumable vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com