Preparation method of low self-discharge nickel-metal hydride battery

A nickel-metal hydride battery, self-discharge technology, applied in the manufacture of alkaline batteries, battery electrodes, alkaline batteries, etc., can solve the problems of increased battery self-discharge, easy to lose powder, etc., to reduce self-discharge and less self-discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

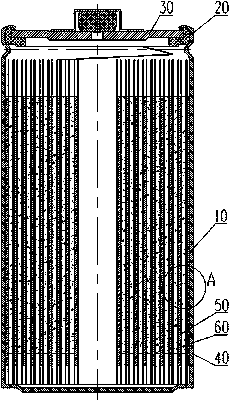

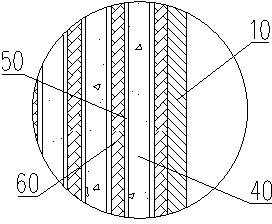

[0023] See figure 1 and figure 2 As shown: a low self-discharge nickel-metal hydride battery, including a cylindrical steel case 10 , the upper opening of the steel case 10 is provided with a combined cap 30 through a sealing ring 20 . Meanwhile, the steel case 10 is provided with a positive electrode sheet 40 and a negative electrode sheet 60 separated by a diaphragm 50 .

[0024] The preparation method of the low self-discharge nickel-metal hydride battery comprises:

[0025] 1) Prepare the semi-finished positive electrode, the steps are:

[0026] a. Preparation of the positive electrode substrate: the positive electrode substrate adopts a surface density of 250g / m 2 Preparation of foamed nickel;

[0027] B, preparation of positive electrode surface material: get 800g of cobalt-coated spherical nickel hydroxide, 10g of cobaltous oxide or cobalt hydroxide, 2g of yttrium oxide, 8g of erbium oxide, 10g of PTFE emulsion with a mass percentage of 60%, 10g The CMC powder...

Embodiment 2

[0038] The structure of the low self-discharge nickel-hydrogen battery is the same as in Example 1, and its preparation method comprises:

[0039] 1) Prepare the semi-finished positive electrode, the steps are:

[0040] a. Preparation of positive electrode substrate: the positive electrode substrate adopts a surface density of 300g / m 2 Preparation of foamed nickel;

[0041] b. Preparation of positive electrode surface material: take 900g of cobalt-coated spherical nickel hydroxide, 50g of cobaltous oxide or cobalt hydroxide, 30g of zirconium dioxide, 10g of titanium dioxide, 10g of ytterbium oxide, and the mass percentage of 20g is 65%. PTFE emulsion, 20g of CMC powder, after that, mix the aforementioned materials;

[0042] c. Apply the surface material of the positive electrode evenly on the positive electrode substrate, and roll it to a thickness of 0.5 mm. After that, it is made into a semi-finished positive electrode after conventional cutting, spot w...

Embodiment 3

[0052] The structure of the low self-discharge nickel-hydrogen battery is the same as in Example 1, and its preparation method comprises:

[0053] 1) Prepare the semi-finished positive electrode, the steps are:

[0054] a. Preparation of the positive electrode substrate: the positive electrode substrate adopts a surface density of 500g / m 2 Preparation of foamed nickel;

[0055] b, preparation of positive electrode surface material: get 950g of cobalt-coated spherical nickel hydroxide, 100g of cobaltous oxide or cobalt hydroxide, 10g of yttrium oxide, 20g of erbium oxide, 70g of titanium dioxide, 30g of 70% by mass PTFE emulsion, 30g of CMC powder, after that, mix the aforementioned materials evenly;

[0056] c. Spread the surface material of the positive electrode evenly on the positive electrode substrate, and roll it to a thickness of 0.7mm. Afterwards, after conventional cutting, spot welding of tabs, and softening, the positive electrode semi-finished product is made;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com