Anchoring agent and preparation method and application thereof

An anchoring agent and reaction technology, applied in the direction of adhesives, film/sheet adhesives, film/sheet release liners, etc., can solve the problem that the adhesion between the release film and the substrate and the peeling performance cannot be improved at the same time, To achieve the effect of low peel force, good adhesion, and improved storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

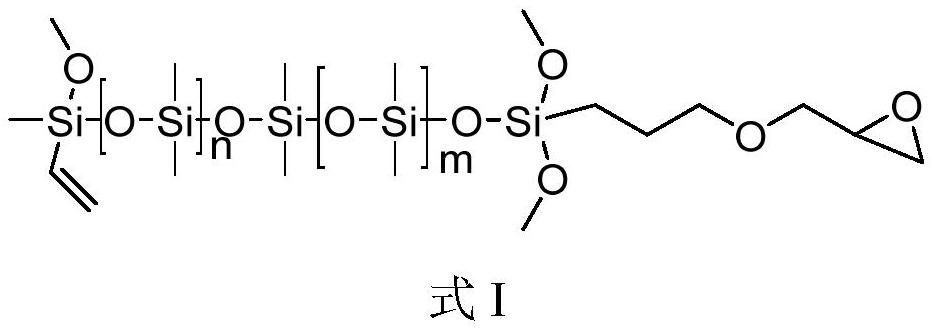

[0049] The present invention prepares a kind of anchoring agent, prepares according to the following method:

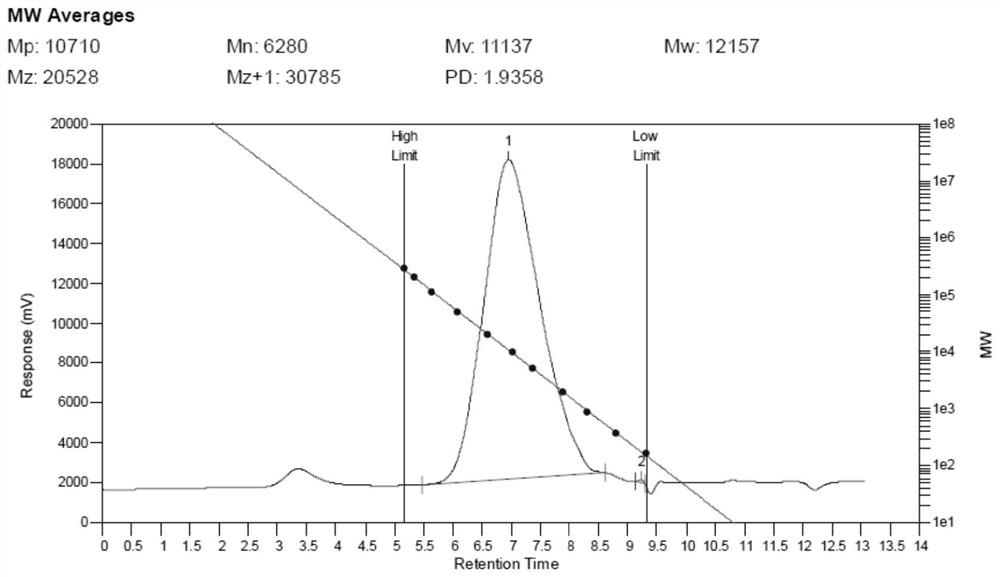

[0050] S1.190g (molecular weight: 200, 0.95mol) double-terminated hydroxyl polysiloxane, 125.6g (0.95mol) methylvinyldimethoxysilane and 0.094g KOH were reacted at 60°C for 3h to obtain a molecular weight of 510, Organosiloxane A containing vinyl groups and silanol groups with a PDI of 1.83;

[0051] S2.145.2g (0.28mol) organosiloxane A obtained from S1, 82.7g (0.35mol) 3-(2,3-epoxypropoxy)propyltrimethoxysilane and 0.068g KOH were reacted at 60°C After 3 hours, an anchoring agent with a molecular weight of 1123 and a PDI of 1.73 was obtained.

Embodiment 2

[0053] The present invention prepares a kind of anchoring agent, prepares according to the following method:

[0054] S1.150g (molecular weight: 7000, 0.021mol) double-terminated hydroxyl polysiloxane, 2.77g (0.021mol) methylvinyldimethoxysilane and 0.045g KOH were reacted at 60°C for 3h to obtain a molecular weight of 7700, Organosiloxane A containing vinyl groups and silanol groups with a PDI of 1.87;

[0055] S2.120g (0.015mol) organosiloxane A obtained from S1, 5.42g (0.019mol) 3-(2,3-epoxypropoxy)propyltriethoxysilane and 0.0037g KOH were reacted at 60°C After 3 hours, an anchoring agent with a molecular weight of 8312 and a PDI of 1.77 was obtained.

Embodiment 3

[0057] The present invention prepares a kind of anchoring agent, prepares according to the following method:

[0058] S1.300g (molecular weight: 200, 1.5mol) double-terminated hydroxyl polysiloxane, 240.4g (1.5mol) methylvinyldiethoxysilane and 0.16g KOH were reacted at 60°C for 3h to obtain a molecular weight of 552, Organosiloxane A containing vinyl groups and silanol groups with a PDI of 1.91;

[0059] S2.180g (0.326mol) organosiloxane A obtained from S1, 100.4g (0.408mol) 2-(3,4-epoxycyclohexane) ethyltrimethoxysilane and 0.084g KOH were reacted at 60°C After 3 hours, an anchoring agent with a molecular weight of 1240 and a PDI of 1.81 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com