Heat-resistant UV visbreaking glue composition and UV visbreaking protective film

A composition and protective film technology, applied in the direction of non-polymer organic compound adhesives, polyurea/polyurethane adhesives, film/sheet adhesives, etc., can solve the problem of low peeling force, large peeling force, The UV adhesion-reducing protective film is resistant to high temperature and other problems, and achieves the effect of low peeling force, no residual glue left by the peeling force, and widening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

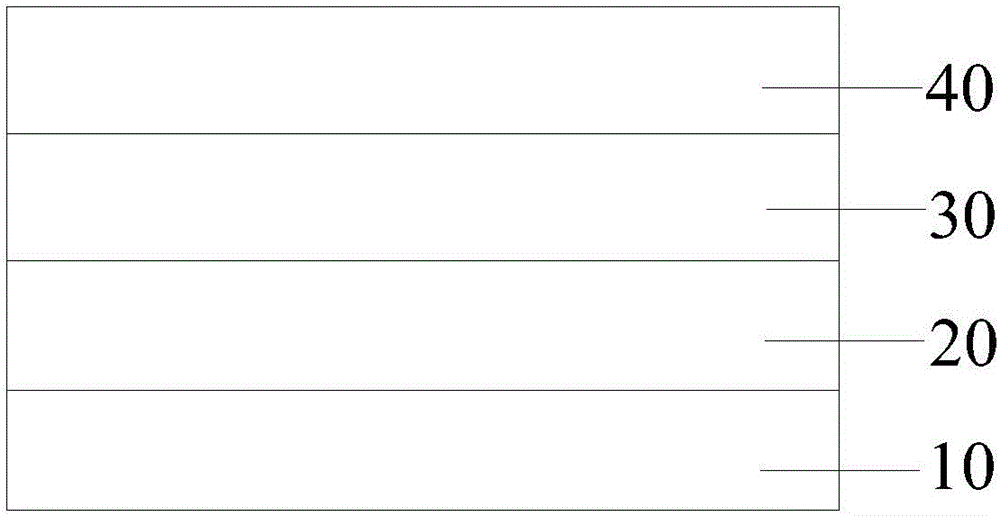

Image

Examples

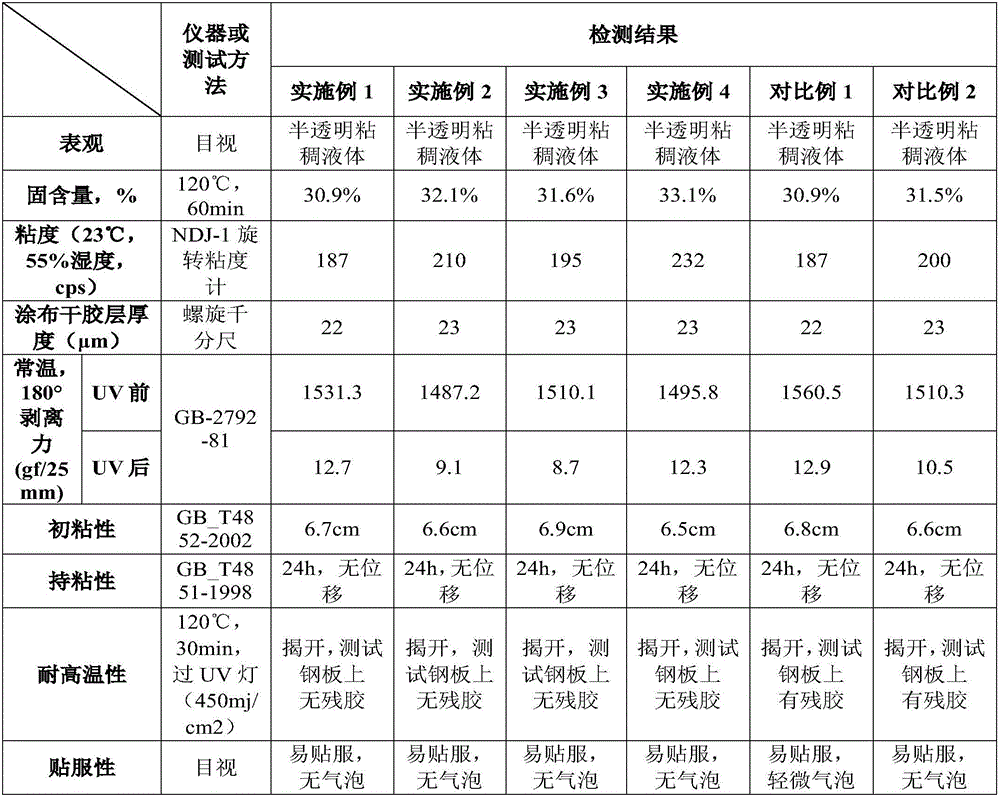

Embodiment 1

[0026] Coating PET primer: use the company's self-made corona PET, the model is KFDN-50G4, the thickness of the substrate is 50um, the primer is 50g of water-based polyurethane emulsion (Shanghai Sisheng) model HD2081, and carboethylamine crosslinking agent 2.5g, 10g of deionized water, stir evenly, wait for defoaming for 10 minutes, and then apply it on the corona surface of the PET substrate. Uniform coating;

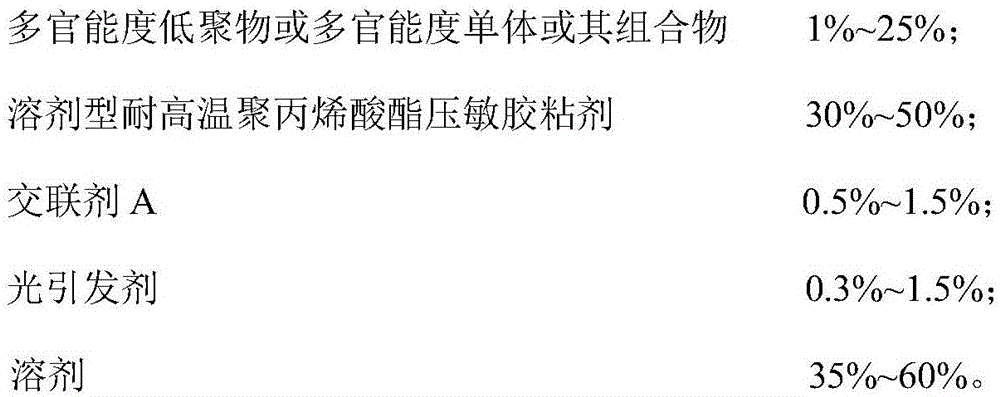

[0027] Preparation of heat-resistant UV viscosifying adhesive composition: drop 28gDR-U202 (manufactured by Changxing Chemical Co., Ltd.), 8gEM231 (manufactured by Changxing Chemical Co., Ltd.), 120gDS-203A (manufactured by Dongsheng Chemical) and 118g ethyl acetate in a 500ml shading cup , stir evenly with a disperser, then add 1.9g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 8.5gN75 (20% concentration of ethyl acetate dilution) and 0.32gGA-240 (5 % concentration of ethyl acetate diluent), after adding, stir at a rotating speed of 50...

Embodiment 2

[0030] Coating PET primer: use the company's self-made corona PET, the model is KFDN-50G4, the thickness of the substrate is 50um, the primer is 50g of water-based polyurethane emulsion (Shanghai Sisheng) model HD2081, and carboethylamine crosslinking agent 2.5g, 10g of deionized water, stir evenly, wait for defoaming for 10 minutes, and then apply it on the corona surface of the PET substrate. Uniform coating;

[0031] Prepare a heat-resistant UV viscosifying adhesive composition: put 31gDM87A (manufactured by Double Bond Chemical Co., Ltd.), 7.5gEM231 (manufactured by Changxing Chemical Co., Ltd.), 110gDS-201A (manufactured by Dongsheng Chemical) and 120g isopropyl in a 500ml shading cup alcohol, stir evenly with a disperser, then add 1.9g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 9gN75 (20% concentration of isopropanol dilution) and 0.24gGA-240 (5 % concentration of isopropanol diluent), after adding, stir with a rotating speed of 500rpm ...

Embodiment 3

[0034] Coating PET primer: use the company's self-made corona PET, the model is KFDN-50G4, the thickness of the substrate is 50um, the primer is 50g of water-based polyurethane emulsion (Shanghai Sisheng) model HD2081, and carboethylamine crosslinking agent 2.5g, 10g of deionized water, stir evenly, wait for defoaming for 10 minutes, and then apply it on the corona surface of the PET substrate. Uniform coating;

[0035] Preparation of heat-resistant UV viscosifying adhesive composition: drop 35g8415 resin (manufactured by Allnex), 3gEM264 (manufactured by Changxing Chemical Co., Ltd.), 100g1537-2 (Toyo Ink) and 120g ethyl acetate in a 500ml shading cup. Stir evenly, then add 2.0g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 8.5g N75 (20% concentration of ethyl acetate dilution) and 0.30gGA-240 (5% concentration) while stirring in order Ethyl acetate diluent), after adding, stir at a speed of 500rpm for 30min, let it stand for more than 30min to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com