Making method for anti-fake soundless adhesive tape

A tape and film technology, which is applied in the production process of anti-counterfeiting silent tape, can solve the problems of high noise and inability to identify the unpacking state of the carton, and achieve the effect of reasonable arrangement, easy operation and strong bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the release agent in the present invention is: according to the proportioning ratio of the components in the formula, sequentially add organosilicon polymer, solvent, crosslinking agent, other additives and crosslinking catalyst into the stainless steel reaction vessel, then stirrer at 200R / Stirring speed at 21-25°C for 20 minutes.

[0036] The front and back surfaces of BOPP film are coated with LOGO release agent and light peeling force release agent respectively. The adhesion strength between light peeling force release agent and BOPP film is relatively low, and there is a silent effect when the tape is pulled from the roll. No noise will be produced. The bonding strength of LOGO release agent and BOPP film is lower than that of LOGO release agent and adhesive. After the tape is peeled off, dry glue with LOGO will be left on the sealed item.

[0037] Step 4: The BOPP film after the release agent treatment is coated with water-based acrylic ...

specific Embodiment

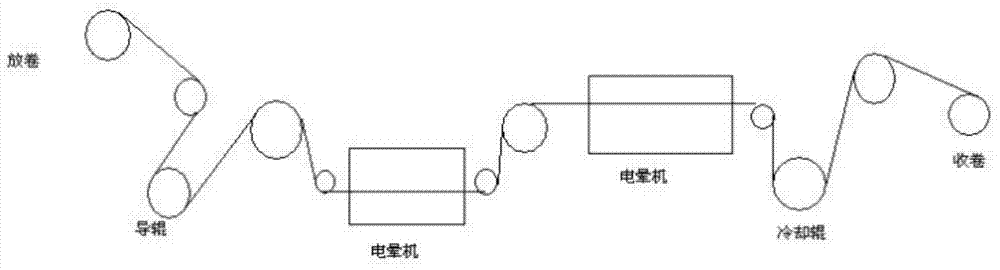

[0038] 1) The BOPP film is conveyed to the corona machine by the guide roller. Under the conditions of power of 20KW, temperature of 40°C and tension of 15-25kgf, corona treatment is performed on the front and back surfaces of the BOPP film, cooled by the cooling roller, and then The winding tension is 10-19kgf, and the guide roller is winding at a speed of 70m / min; the thickness of the BOPP film selected is 28-50μm.

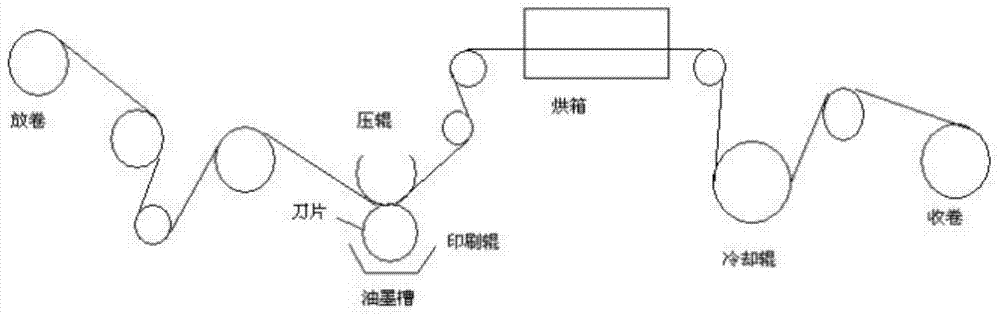

[0039]2) The corona-treated BOPP film is printed ink on the front surface of the BOPP film through a printing roller with a printing tension of 15 to 25 kgf, and is dried in an oven at a temperature of 100° C. The roll tension is 10~19kgf, and the speed is 70m / min. The guide roller is wound.

[0040] 3) The BOPP film after ink printing is coated with a light release force release agent on the reverse surface of the BOPP film through an anilox roller with a coating tension of 20-25kgf, and then passed through the LOGO mark printing roller on the front surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com