Online-coated ultralow-release force release type polyester film and preparation method thereof

A technology of polyester film and peeling force, which is applied in the field of online coating release polyester film and its preparation, which can solve the problems of poor printing quality, inability to meet high-speed labeling, and affecting printing ink adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

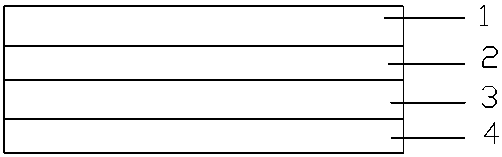

[0018] Such as figure 1 As shown, a kind of online coating ultra-low peeling force release polyester film is provided with silicone coating, upper polyester matt layer, core layer and lower polyester matt layer successively from top to bottom, wherein, the first One layer is silicone coating with ultra-low peeling force, using low peeling force water-based silicone emulsion, the thickness is preferably 1-2μm; the second layer is the upper polyester matte layer, its thickness is preferably 6μm, using matte Optical polyester masterbatch, added with silica friction agent, the concentration of silica is less than 10%, which can improve the winding performance of the film, and because there is a first layer of silicone coating on it, it also in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com