Vibrating diaphragm and micro acoustic generator equipped with vibrating diaphragm

A technology of thin film and adhesive film layer, which is applied in the direction of polymer material diaphragm, non-planar diaphragm/paper cone, sensor, etc., which can solve the difficulty in meeting the requirements of high sound quality, poor stability of micro-speakers, and poor heat resistance of diaphragm To achieve the effect of maintaining long-term stability, high rigidity and improving damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

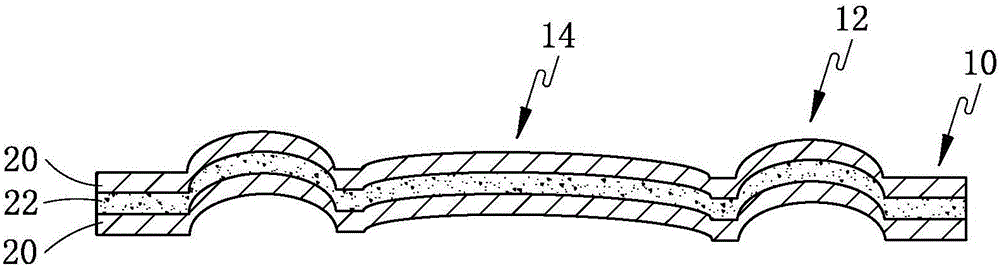

Embodiment approach 1

[0032] like figure 1 As shown, the diaphragm is a three-layer composite structure, consisting of two thermoplastic elastomer layers 20 and a layer of adhesive film 22, the thermoplastic elastomer layer 20 is located on the surface, and the adhesive film layer 22 is sandwiched between the two thermoplastic elastomer layers 20 between. Wherein: two layers of thermoplastic elastomer layers 20 can be selected from the same material, such as a material in TPEE film, TPU film or TPAE film, or two different materials, such as TPEE film and TPU film or TPU film and TPAE film, etc.; the film layer 22 is made of acrylic film or silica gel film.

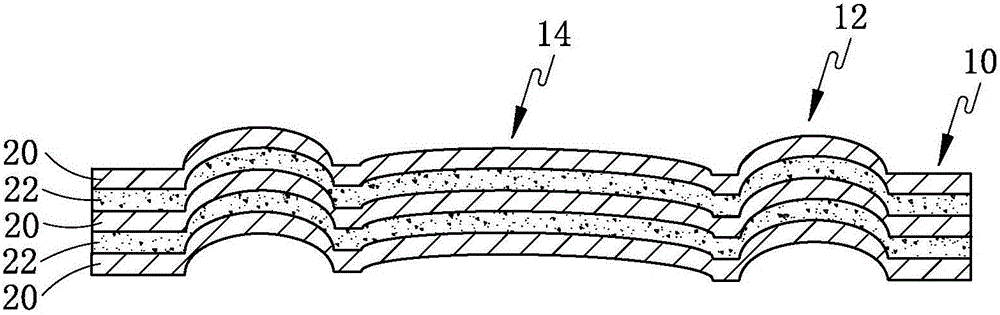

Embodiment approach 2

[0034] like figure 2 As shown, the diaphragm has a five-layer composite structure, consisting of three thermoplastic elastomer layers 20 and two adhesive film layers 22. The thermoplastic elastomer layers 20 are still located on the surface, and the adhesive film layers 22 are located in the middle and are alternately stacked. Wherein: the three-layer thermoplastic elastomer layer 20 can be selected from the same material, such as a material in TPEE film, TPU film or TPAE film, or two different materials or three different materials; two layers The film layer 22 can be made of the same material, such as one of acrylic film or silicone film, or two different materials, that is, one layer is an acrylic film and the other is a silicone film.

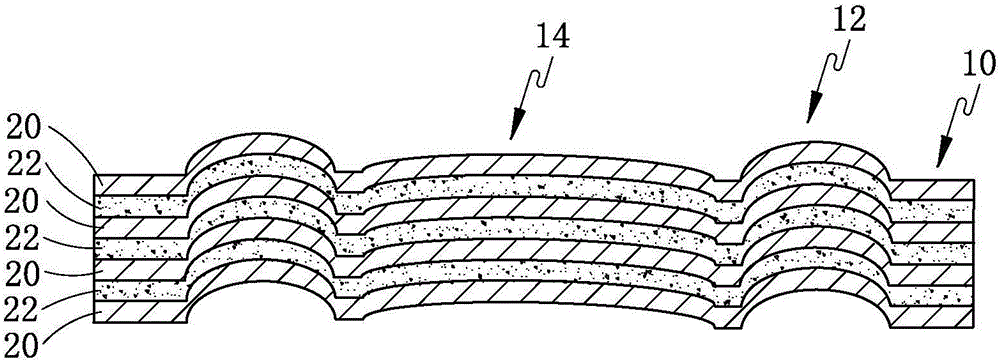

Embodiment approach 3

[0036] like image 3 As shown, the diaphragm is a seven-layer composite structure, consisting of four thermoplastic elastomer layers 20 and three adhesive film layers 22 . Same as the previous two embodiments, the four thermoplastic elastomer layers 20 can all be made of the same material or different materials; the three film layers 22 can also be made of the same material or different materials.

[0037] The vibrating membrane of the present invention is composed of a thermoplastic elastomer layer and an adhesive film layer, has high rigidity and strong heat resistance, effectively improves the damping performance of the micro-speaker, and reduces the total harmonic distortion and damping coefficient of the micro-speaker. The long-term stability of F0 is maintained, and the sound quality of the micro-sounder is greatly improved.

[0038] A miniature sounder comprising the above-mentioned vibrating membrane, including a vibrating system and a magnetic circuit system, the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com