Negative photoresist-based diffuser photo-etching process

A technology of negative photoresist and photolithography process, which is applied in the field of negative photoresist photolithography process and diffusion sheet photolithography process based on negative photoresist, which can solve the problem of uneven doping and uncontrollable light field. , uneven light field and other problems, to achieve the effect of simple preparation process, reduced device cost, and little effect of ultraviolet light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

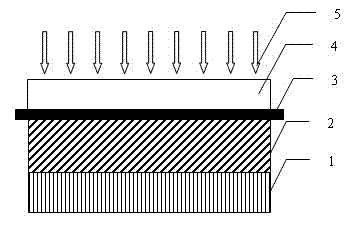

[0065] Fabrication of SU-8 Negative Photoresist Grooves on Monocrystalline Silicon Wafers

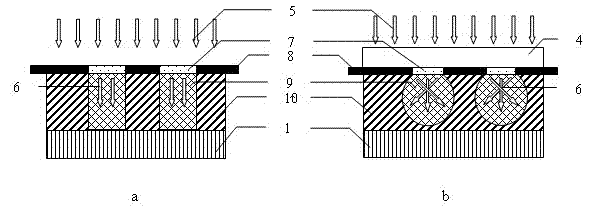

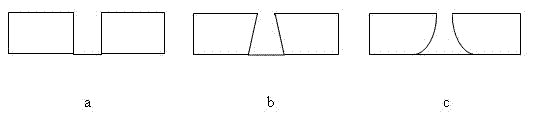

[0066] Firstly, SU-8 photoresist 2 is spin-coated on a single-side polished single-crystal silicon wafer substrate 1, then pre-baked on a hot plate, and cooled naturally to room temperature. Then place the diffuser 4 on the mask plate 3, use a photolithography machine to perform ultraviolet contact exposure, then pre-baked on a hot plate, and finally develop in the developer solution PMGEA to obtain the SU-8 negative photo Resist grooves such as Figure 5 As shown, some of its cross-sectional lines are as Figure 4 shown.

Embodiment 2

[0068] Fabrication of NR9-3000PY negative photoresist photonic crystal on K9 optical glass

[0069] First, NR9-3000PY photoresist 2 was spin-coated on a K9 optical glass substrate 1, then pre-baked on a hot plate, and cooled to room temperature naturally. Then place the diffusion sheet 4 on the mask plate 3, use a photolithography machine to perform ultraviolet contact exposure, then pre-bake on a hot plate, and finally develop in the developer solution R6 to obtain the obtained NR9-3000PY negative photo Resist photonic crystal unit such as Figure 6 As shown, a part of its cross-section is shown as Figure 4 As shown, the negative photoresist columns and negative photoresist wells can be produced due to the difference of the mask plate, and the photonic crystal such as Figure 7 shown. )

[0070] According to the graphic cross-section lines made in embodiment 1 and embodiment 2, the exposure process of the diffuser negative photoresist lithography proposed by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com