Smart energy carbon fiber complex core production line

A smart energy and carbon fiber technology, applied in carbon-silicon compound conductors, manufacturing rigid tube cables, electrical components, etc., can solve the problems affecting the safe operation of composite core performance wires, increase of old glue, etc., to reduce the generation of old glue, reduce Wasteful, tight storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

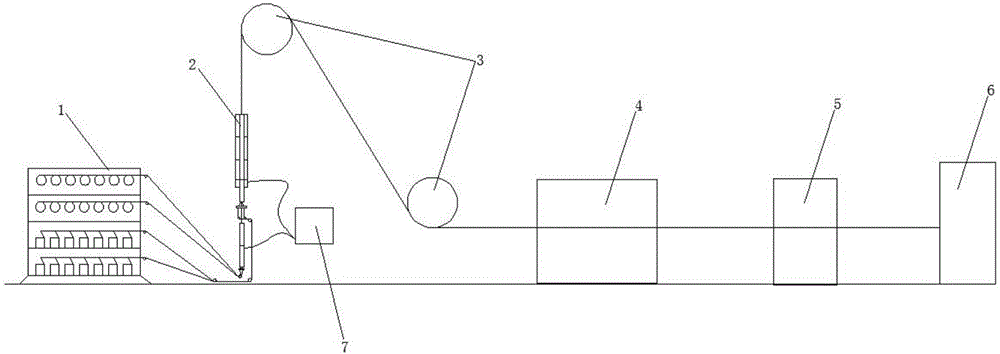

[0032] See Figure 1 to Figure 8 , the carbon fiber composite core production line for smart energy in this embodiment includes a creel 1, a preform curing device 2, a steering wheel set 3, a traction system 4, an online nondestructive testing system 5 and a wire take-up system 6 arranged in sequence according to the production process, And a glue injection system 7 for injecting glue into the preform curing device 2 .

[0033] Carbon fiber and glass fiber are placed on creel 1. The carbon fiber adopts shaft type pay-off, while both carbon fiber and glass fiber adopt tension-free pay-off.

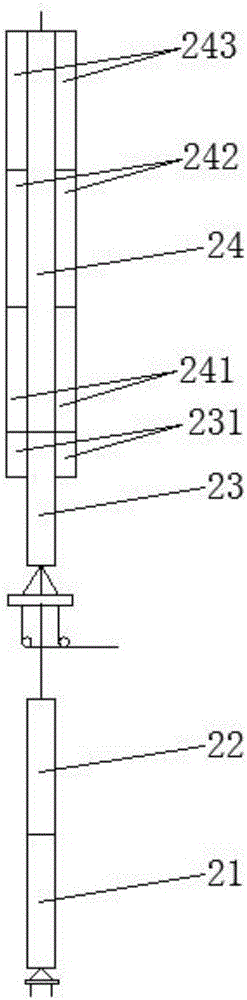

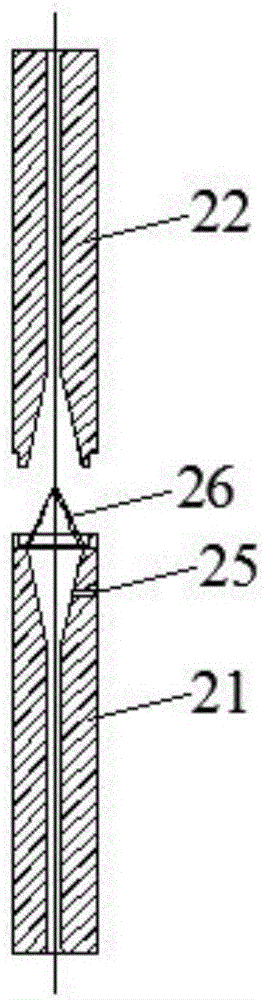

[0034] The preforming curing device 2 is a vertical structure, including a carbon fiber inlet mold 21 , a preforming mold 22 , a glass fiber inlet mold 23 and a curing mold 24 arranged in sequence from bottom to top. The top of the carbon fiber inlet mold 21 is fixedly connected with the preforming mold 22 , and the top of the glass fiber inlet mold 23 is fixedly connected with the curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com