Production method of BTTZ fireproof cable

A technology for fire-resistant cables and production methods, which is applied in the manufacture of rigid pipe cables, cable/conductor manufacturing, and conductor/cable insulation, etc. The effect of production site, production cost reduction and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

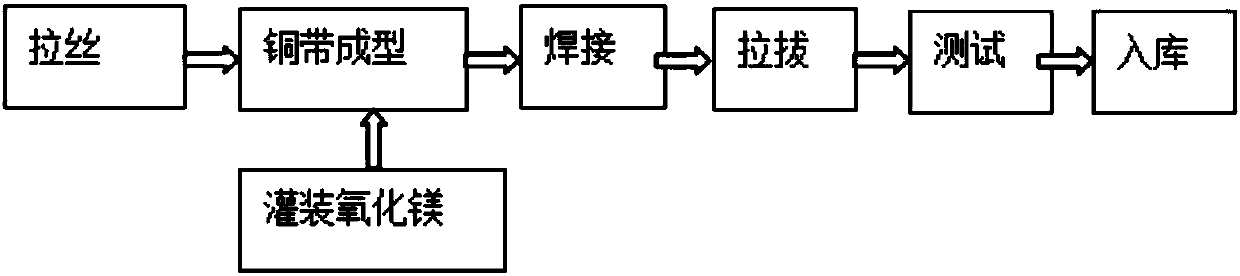

[0042] See figure 1 In the embodiment of the present invention, a method for producing a BTTZ fireproof cable includes the following steps:

[0043] 1) Using 3mm thick pure copper strip with 99.99% copper content, after 10 sets of shaping molds, the pure copper strip is gradually bent from a flat state to a copper tube state;

[0044] 2) Before the two sides of the copper pipe are close to closing, use 8mm pure copper rod as the conductive wire core and fix it in the middle of the copper pipe before the magnesium oxide can be filled; then the equipment will automatically fill the magnesium oxide;

[0045] 3) Weld the copper tube after it is closed;

[0046] 4) The welded copper tube is directly transported from the guide wheel to the front guide wheel. A total of 10 groups of guide wheels are required. The guide wheels are arranged in 360 degrees, and each group of guide wheels is 0.2mm larger than the previous group of guide wheels. Compact the magnesium oxide insulating layer insid...

Embodiment 2

[0049] In the embodiment of the present invention, a method for producing a BTTZ fireproof cable includes the following steps:

[0050] 1) Using 2mm thick pure copper strip with 99.99% copper content, after 10 sets of shaping molds, the pure copper strip is gradually bent from a flat state to a copper tube state;

[0051] 2) Before the two sides of the copper pipe are close to being closed, use 6mm pure copper rod as the conductive wire core and fix it in the middle of the copper pipe before the magnesium oxide can be filled; then the equipment will automatically fill the magnesium oxide;

[0052] 3) Weld the copper tube after it is closed;

[0053] 4) The welded copper tube is directly transported from the guide wheel to the front guide wheel. A total of 10 groups of guide wheels are required. The guide wheels are arranged in 360 degrees, and each group of guide wheels is 0.2mm larger than the previous group of guide wheels. Compact the magnesium oxide insulating layer inside;

[0054...

Embodiment 3

[0056] In the embodiment of the present invention, a method for producing a BTTZ fireproof cable includes the following steps:

[0057] 1) Using 5mm thick pure copper strip with 99.99% copper content, after 10 sets of shaping molds, the pure copper strip is gradually bent from a flat state to a copper tube state;

[0058] 2) Before the two sides of the copper tube are close to being closed, use a 10mm pure copper rod as the conductive core to be fixed in the middle of the copper tube before the canning of magnesium oxide; then the equipment will automatically fill the magnesium oxide;

[0059] 3) Weld the copper tube after it is closed;

[0060] 4) The welded copper tube is directly transported from the guide wheel to the front guide wheel. A total of 10 groups of guide wheels are required. The guide wheels are arranged in 360 degrees, and each group of guide wheels is 0.2mm larger than the previous group of guide wheels. Compact the magnesium oxide insulating layer inside;

[0061] 5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com