Producing method of niobium three stannum cable-in-conduit conductors of large superconducting magnets

A technology of cable conductors and superconducting magnets in tubes, applied in the manufacture of rigid tube cables, etc., can solve problems such as irreversible performance degradation, and achieve the effects of reduced displacement and deformation, good contact and support, and good self-support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A method for manufacturing a cable conductor in a niobium-tritin tube of a large superconducting magnet comprises the following steps:

[0026] (1) Pressure, leak detection and flaw detection of stainless steel pipes used as conductor armor;

[0027] (2) Weld the stainless steel pipe into a whole pipe, and inspect the possible defects of the weld;

[0028] (3) Penetrate the superconducting cable of the multi-stage stranded cable into the stainless steel armor;

[0029] (4) Use multi-stage rollers to shrink and shape the conductor, control the void ratio in the conductor to 29-30%, and make the conductor into a rectangular conductor;

[0030] (5) Pre-bend the formed rectangular conductor, and carry out overall pressure leak detection to make the cable conductor in the niobium-three-tin tube.

Embodiment 2

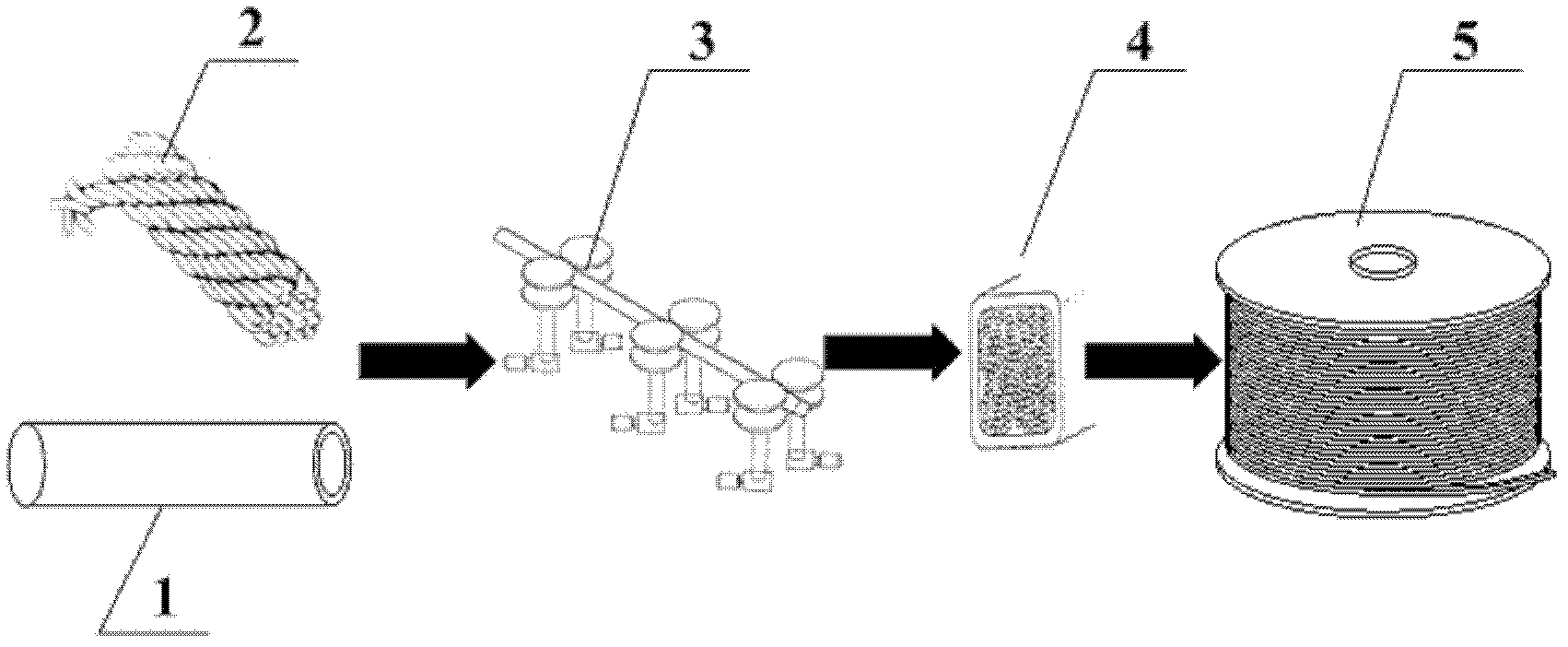

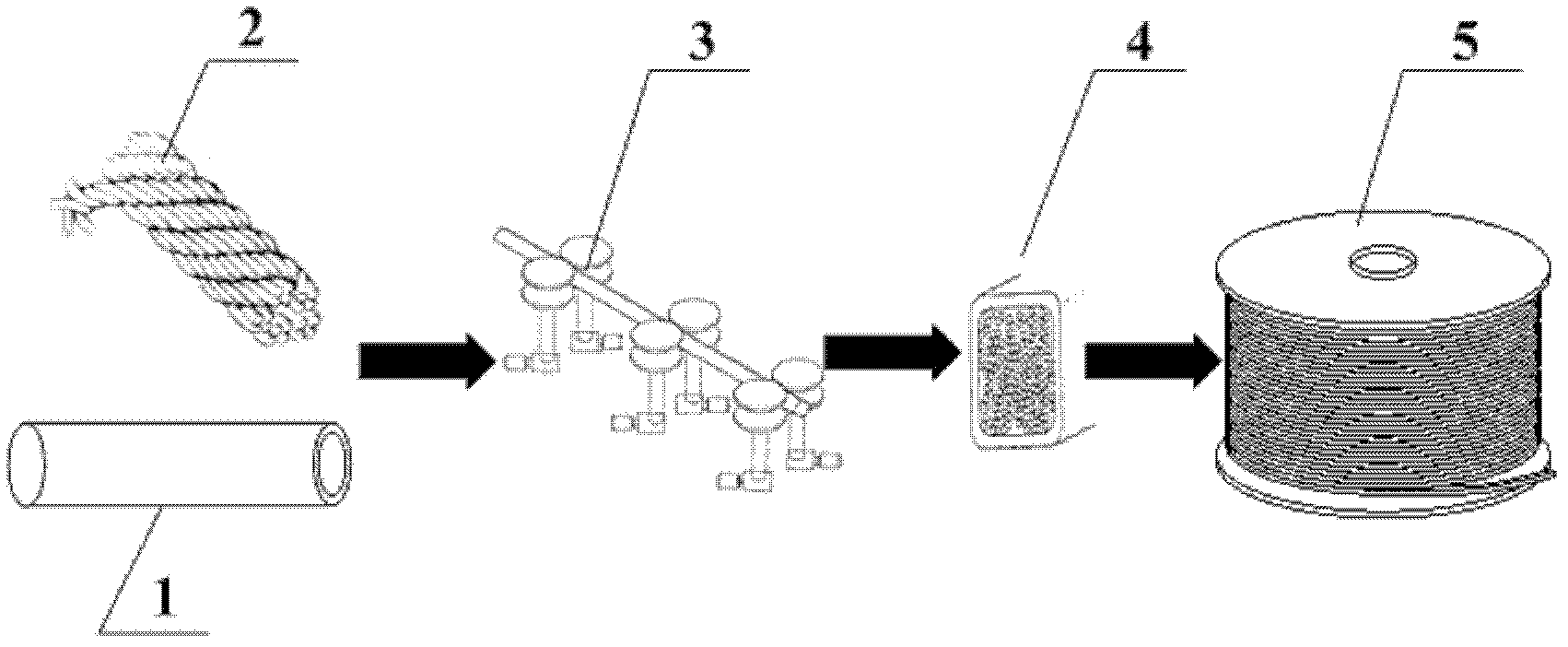

[0031] Example 2: A method for manufacturing a cable conductor in a niobium-three-tin tube of a large superconducting magnet includes the following steps: welding the stainless steel tube 1 into a whole tube, and performing flaw detection and pressure leak detection on the possible defects of the stainless steel tube and the weld seam; The superconducting cable 2 of the twisted cable is penetrated into the stainless steel armor 1, and then passed through the multi-stage roller 3 to reduce the diameter and form it, so that the void ratio in the conductor is controlled at about 30%, and the conductor is made into a rectangular inner cable conductor 4; The formed conductor 4 is pre-bent, fixed on the take-up barrel 5, and subjected to overall pressure leak detection to make a niobium-three-tin inner cable conductor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com