Alloy ground wire production process

A production process and ground wire technology, applied in the field of alloy ground wire production technology, can solve problems affecting production, pipe bursting, etc., to achieve stable production, reduce pipe bursting, and clean up thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

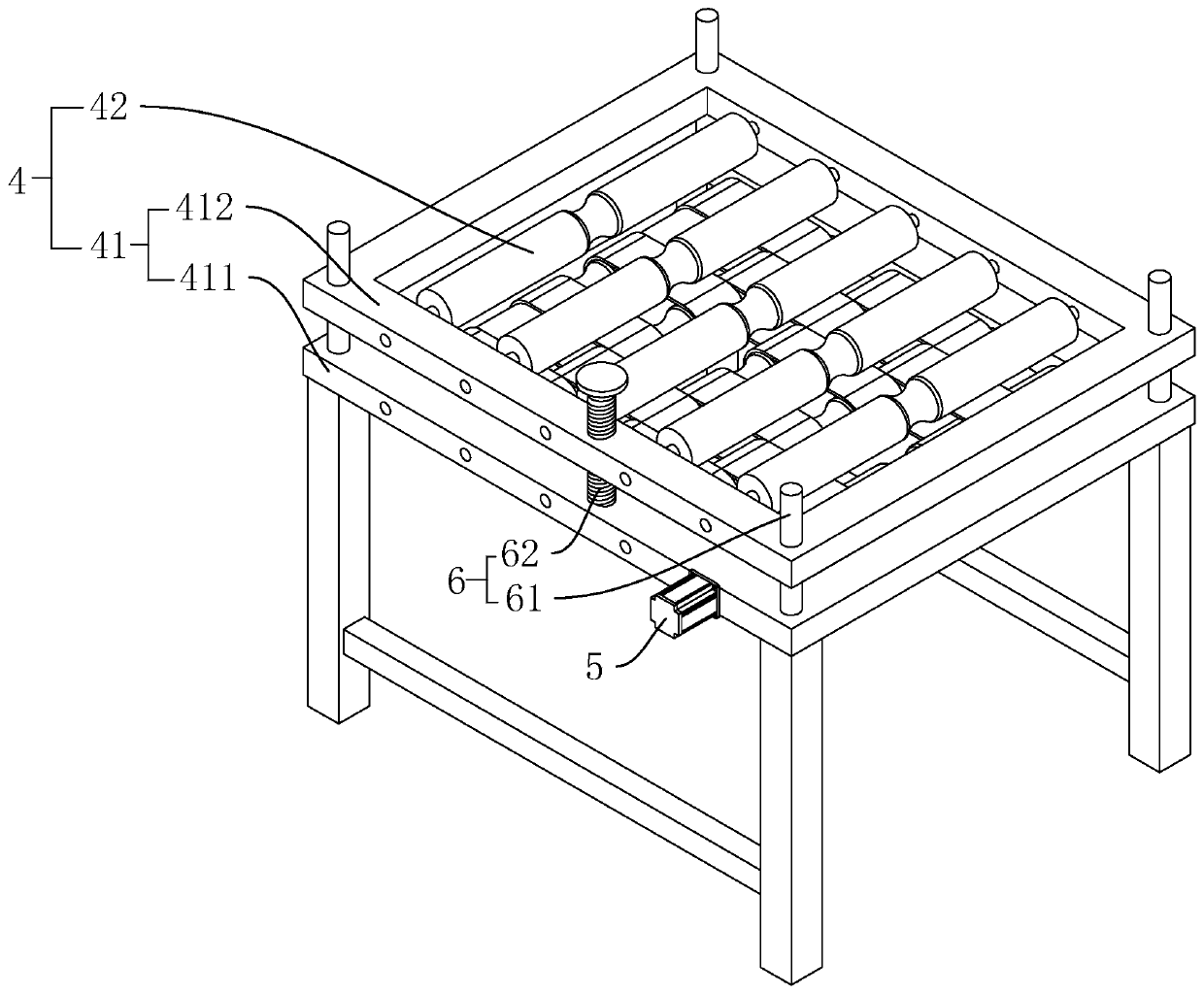

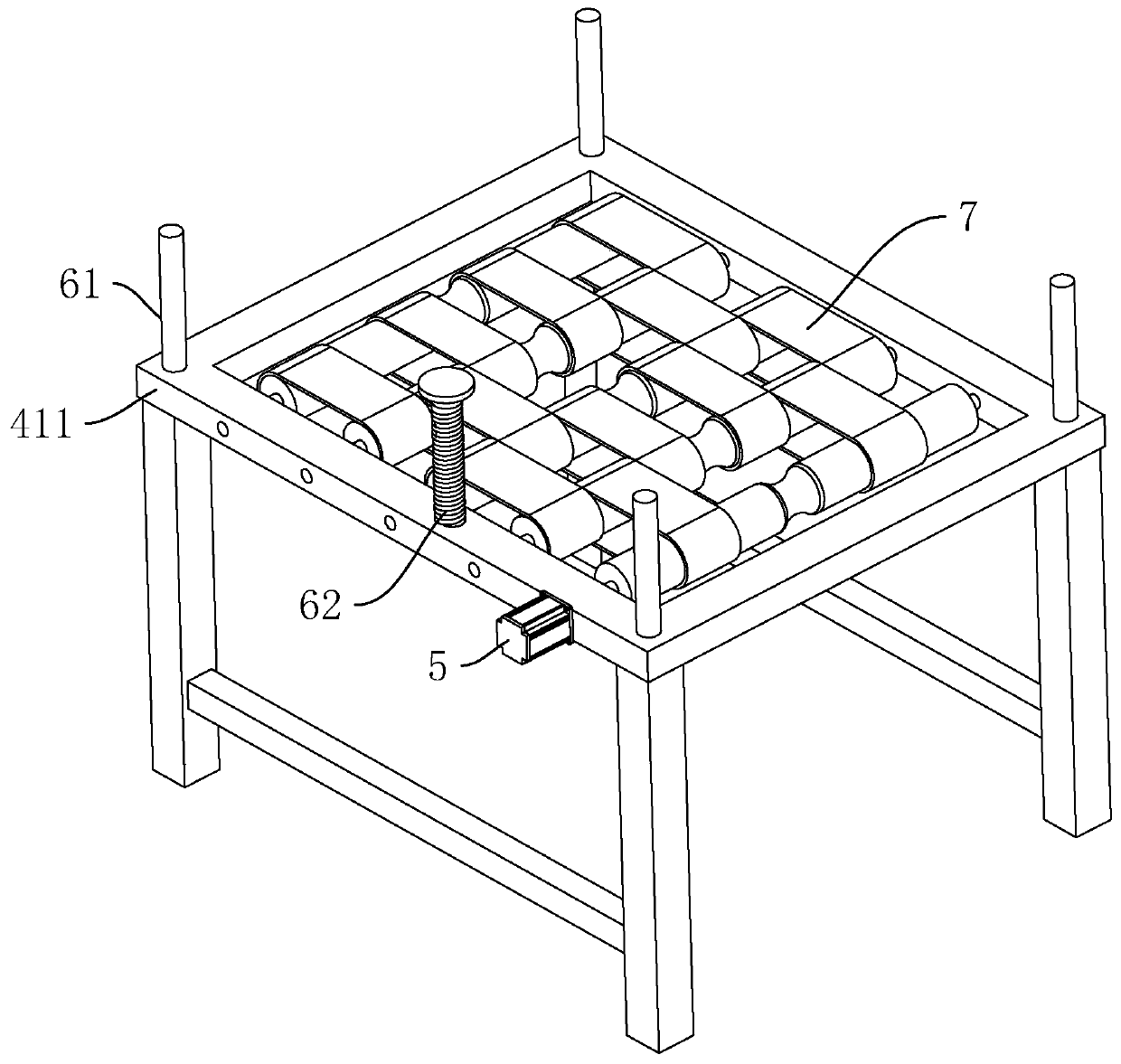

[0041] A production process of alloy ground wire, comprising the following steps:

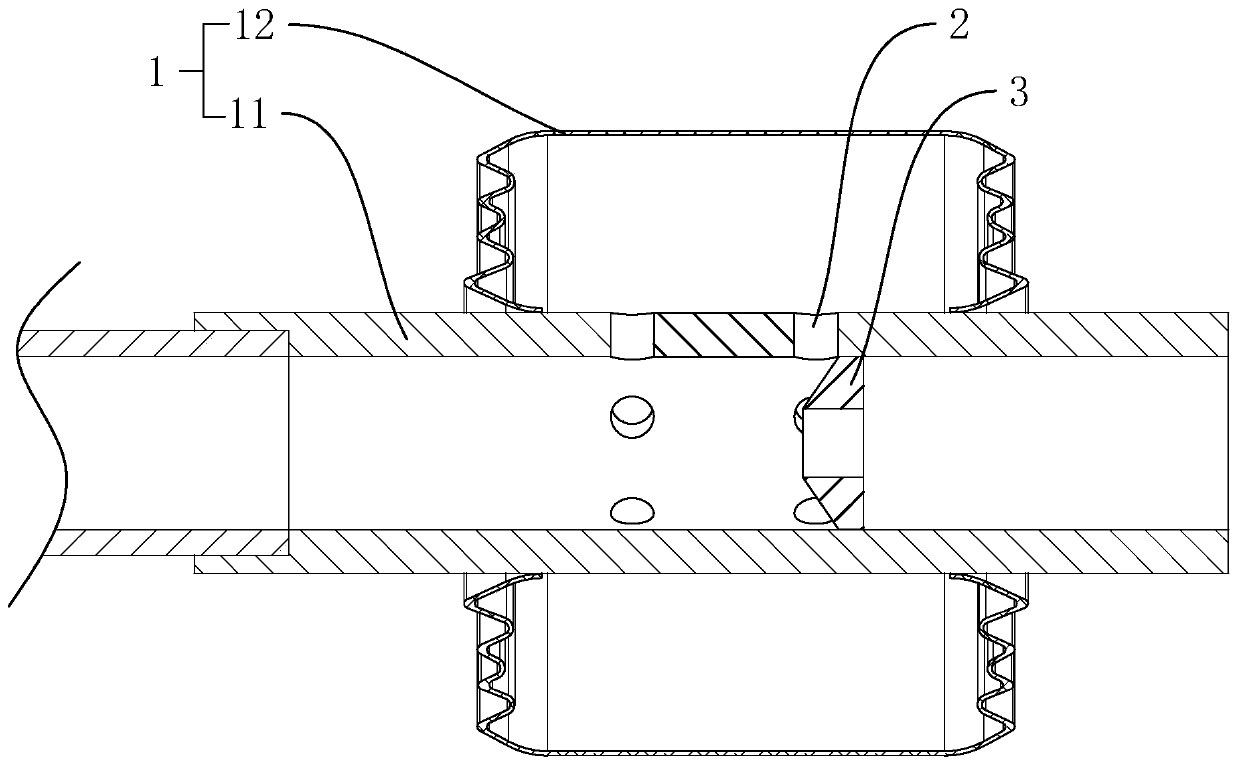

[0042] S1, raw material preparation, preparing copper strands and copper pipes. The copper stranded wire is formed by concentric twisting of multiple soft round copper wires, and the diameter of the copper stranded wire is 5.6-8.9mm. The diameter of the copper tube is 24.5-30mm, and the wall thickness is 0.9-1mm. Prepare copper strands and copper tubes of required length according to requirements, and the length of copper strands should be longer than that of copper tubes.

[0043] S2, copper tube pretreatment, copper tube winding storage, put the copper tube into the heating device to preheat the copper tube, the heating device is usually an oven, control the heating of the heating device to 110-120 degrees Celsius, bake for 5-8 minutes, Then the copper tube is taken out, and air is fed into one end of the copper tube through the blowing device and blown out from the other end. When blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com