Metal wrinkled external conductor forming device of radio-frequency telecommunication cable

A technology of radio frequency communication and forming device, which is applied in the direction of cable/conductor manufacturing, manufacturing rigid tube cables, circuits, etc., which can solve problems such as large voltage standing wave ratio and periodic defects of cables, so as to reduce the impact of product performance and reduce product quality. Effect of VSWR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

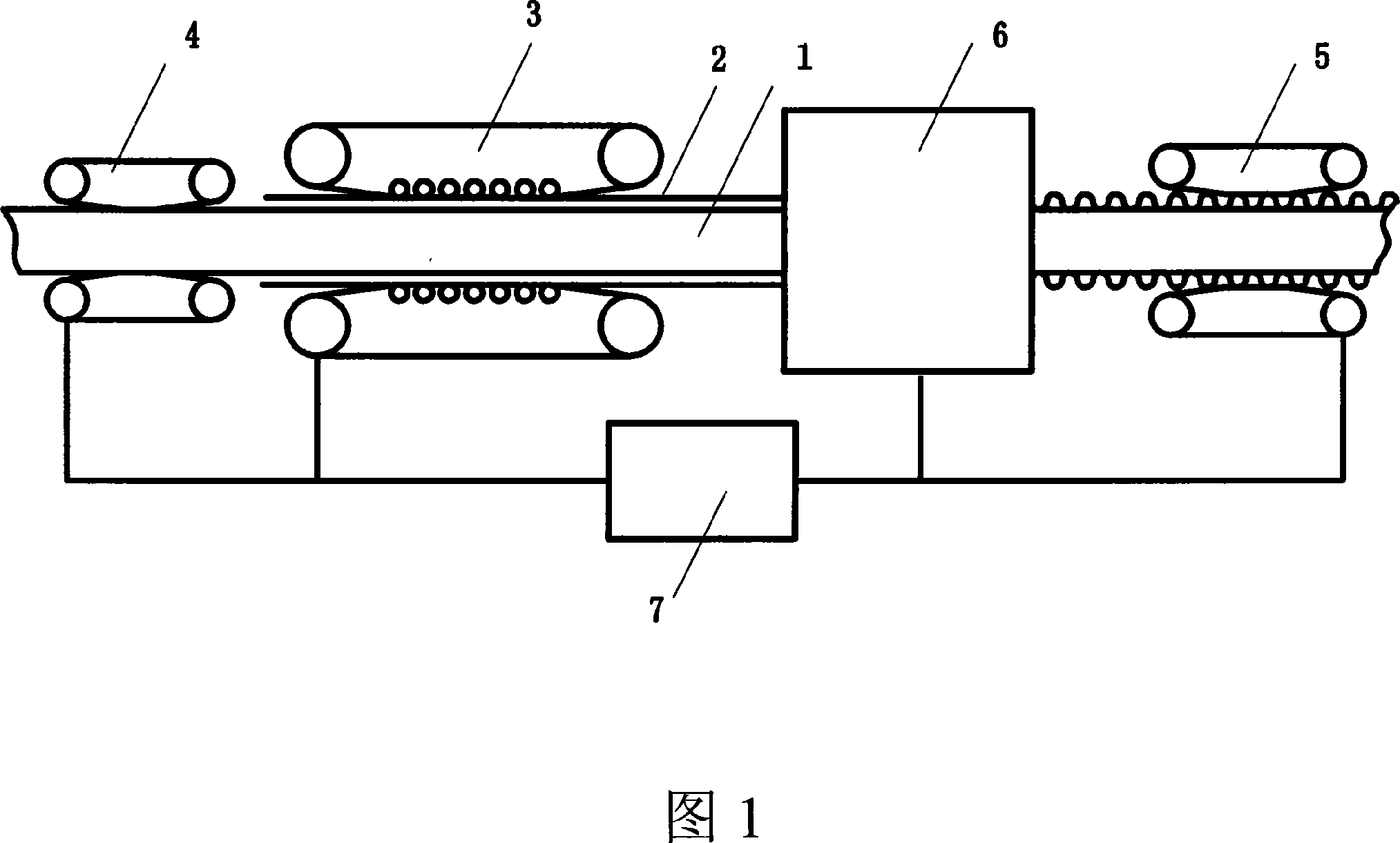

[0008] As shown in FIG. 1 , the present invention includes a main embossing tractor 3, a pay-off auxiliary tractor 4, a take-up auxiliary tractor 5, an embossing host 6, and a control system 7, which is characterized in that the control system 7 is connected to the embossing main tractor Machine 3, take-up auxiliary tractor 5, pay-off auxiliary tractor 4 and embossing host 6. The main pulling machine 3 pushes the outer conductor 2 forward in the direction F shown in the figure, while the cable core 1 is pulled forward by the outer conductor under the pay-off tension N of the pay-off auxiliary pulling. And under the work of the take-up tension P of the take-up auxiliary traction, the bellows rolling task is completed. Through the control system 7, a random and fluctuating signal within a certain range is given to the corrugated main traction machine, 3, the pay-off auxiliary traction 4, the wire take-up auxiliary traction 5, and the corrugated main machine 6, so that the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com