High power bayonet connector

A connector and high-power technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problem of threaded connectors taking up time and space, and achieves a solution to the shortage of equipment space, superior performance and fast speed. The effect of connecting and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

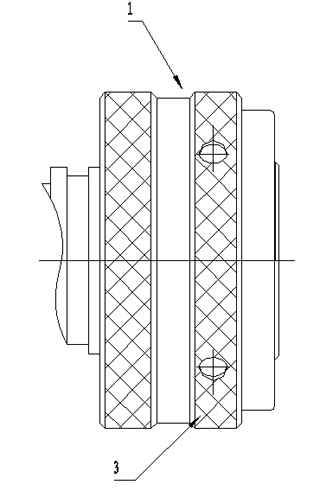

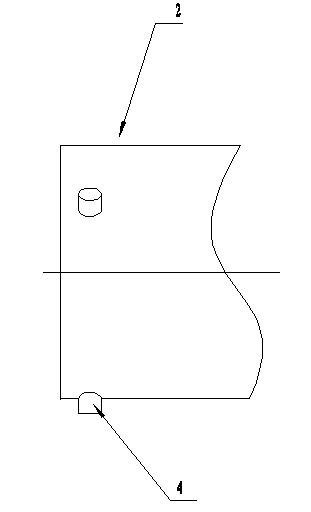

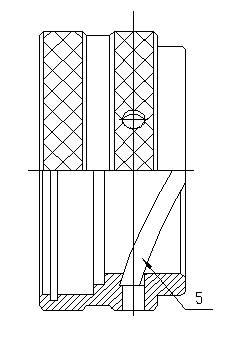

[0015] see figure 1 and figure 2 , including a plug 2 and a socket 1, the socket 1 is provided with a connecting sleeve 3, and the connecting sleeve 3 is provided with three evenly distributed spiral slots 5, and the plug 2 is provided with three staples 4 on the circumference of the front surface of the shell. see image 3 and Figure 4 , The connecting sleeve 3 has three spiral slots 5 inside, and the spiral slots 5 and the spiral slots are 120 degrees relative to each other. see Figure 5 , there are three staples 4 on the circumference of the front surface of the shell, and the distance between the staples 4 and the staples 4 is also relatively 120 degrees, so as to ensure accurate and reliable connection with the three spiral slots 5 of the connecting sleeve 3 .

[0016] When the paired connectors are mated, when the pin 4 of the shell contacts the slot of the connecting sleeve 3, continue to apply force and rotate clockwise to make the pin 4 of the shell move along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com