Railway through ground wire and preparation process thereof

It is a technology of railway through ground wire and preparation process, which is applied in the direction of circuit, manufacturing rigid tube cable, cable/conductor manufacturing, etc. It can solve problems such as cable core breakage, affecting conductivity, and easy to generate sheath tube induced current, etc., to meet the requirements of Use requirements, strong anti-corrosion and stress resistance performance, not easily affected by stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

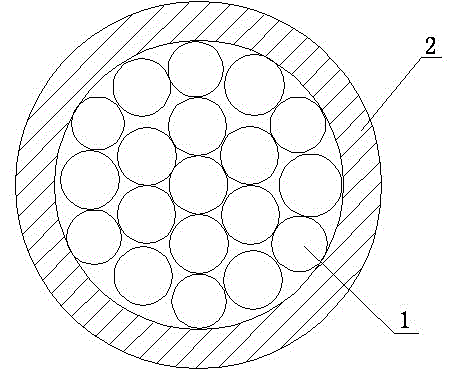

[0025] See figure 1 , The present invention relates to a railway penetrating ground wire, including copper stranded wire 1, the copper stranded wire 1 is formed by spirally winding multiple copper wires, wherein the number of copper wires is 7 to 30, and the copper stranded wire 1 A layer of outer sheath 2 is coated on the outside. The material of the outer sheath 2 is a rare earth copper alloy material. This rare earth copper alloy overcomes the defects of zinc-containing brass and is used as an outer sheath to prevent water seepage, corrosion and Strong anti-stress performance, can ensure the quality and life of the railway through ground wire, its tensile strength and elongation at break are relatively large, and its resistivity is low, which can better meet the requirements of the railway through ground wire. The content of mercury, lead, cadmium, and chromium is small, and it will not pollute the environment after long-term use.

[0026] In order to overcome the problem of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com