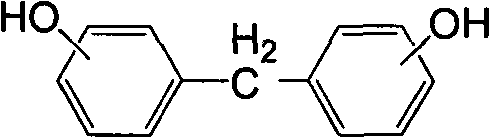

Preparation method of bisphenol F

A technology of bisphenol and phenol, applied in the field of preparation of bisphenol F, can solve the problems of high energy consumption of phenol, high consumption of phenol, large energy consumption of recovery and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

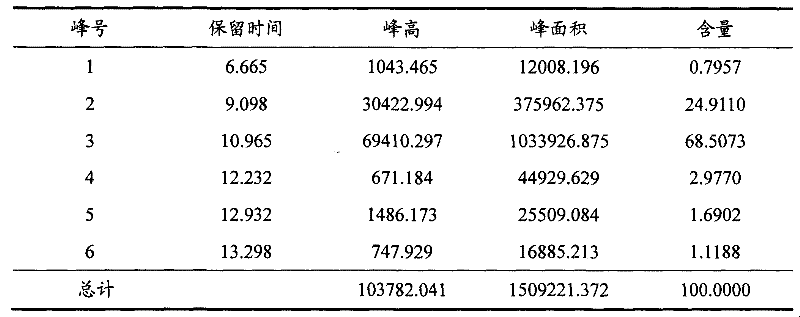

Embodiment 1

[0027] In a 500ml four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and constant pressure dropping funnel, add molten phenol (225g, 2.4mol), 85% phosphoric acid (74g, 0.64mol) and acetic acid (9.6g) , 0.16mol), stir evenly, heat up to 80°C, slowly add 37% formaldehyde (32.5g, 0.4mol) dropwise within 3h, after the addition, react at 80-85°C for 2h, stop stirring, stand for stratification, in Add solid NaHCO to the organic phase 3 Adjust pH=5, filter at 65-70°C, remove the precipitation insoluble in organic phase (mainly NaH 2 PO 4 / NaAc), the filtrate is distilled under high vacuum (2-5mmHg) under reduced pressure to recover unreacted phenol, the distillation temperature is 120-140 ° C, the residual liquid after removing the phenol is dissolved with 5% NaOH, and transferred to another flask The pH is adjusted to 9-10 with hydrochloric acid again. At this time, there is precipitation, and the filter cake is filtered. After drying, the filter ca...

Embodiment 2

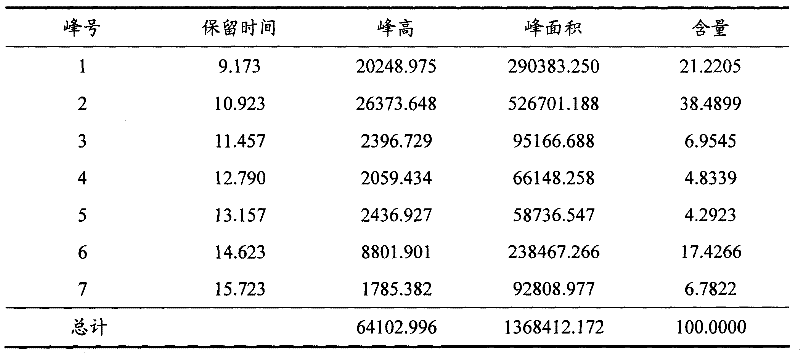

[0032] In a 500ml four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and constant pressure dropping funnel, add molten phenol (225g, 2.4mol), 85% phosphoric acid (74g, 0.64mol) and acetic acid (9.6g) , 0.16mol), stir evenly, heat up to 80°C, slowly add 37% formaldehyde (32.5g, 0.4mol) dropwise within 3h, after adding, react at 95°C for 1h, stop stirring, stand for stratification, in the organic phase Add solid NaHCO 3 Adjust pH=5, filter at 65-70°C, remove the precipitation insoluble in organic phase (mainly NaH 2 PO 4 / NaAc), the filtrate is distilled under high vacuum (2-5mmHg) under reduced pressure to recover unreacted phenol, the distillation temperature is 120-140 ° C, the residual liquid after removing the phenol is dissolved with 5% NaOH, and transferred to another flask The pH is adjusted to 9 with hydrochloric acid again, and a precipitate is precipitated at this time. Filter, and the filter cake is dried to obtain bisphenol F, which...

Embodiment 3

[0037]In a 500ml four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and constant pressure dropping funnel, add molten phenol (225g, 2.4mol), 85% phosphoric acid (74g, 0.64mol) and acetic acid (9.6g) , 0.16mol), stir evenly, heat up to 70°C, add 37% formaldehyde (32.5g, 0.4mol) dropwise within 3h, after the addition, react at 70°C for 2h, stop stirring, stand for stratification, in the organic phase Add solid NaHCO 3 Adjust pH=5, filter at 65-70°C, remove the precipitation insoluble in organic phase (mainly NaH 2 PO 4 / NaAc), the filtrate is distilled under high vacuum (2-5mmHg) under reduced pressure to recover unreacted phenol, the distillation temperature is 120-140 ° C, the residual liquid after removing the phenol is dissolved with 5% NaOH, and transferred to another flask The pH is adjusted to 9 with hydrochloric acid again, and a precipitate is precipitated at this time. Filter, and the filter cake is dried to obtain bisphenol F, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com