Thermosetting resin composition, and prepreg and laminated board made from thermosetting resin composition

A technology of resin composition and prepreg, which is applied in the direction of synthetic resin layered products, lamination, lamination equipment, etc., can solve the problems of heat resistance, water absorption, dielectric properties, flammability, toughness, etc., to achieve peeling The effect of high strength, good solubility and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

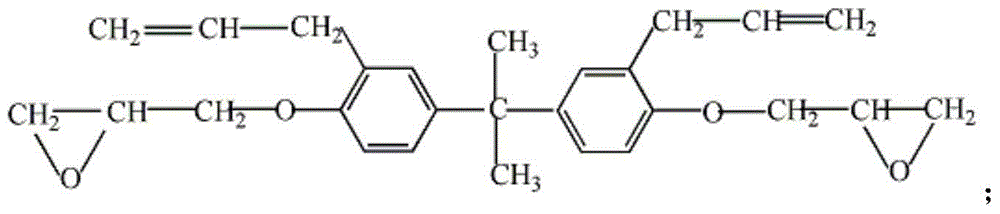

[0044] Take 100g of 4,4'-diphenylmethane bismaleimide, 70g of diallyl bisphenol A diglycidyl ether (epoxy equivalent 256g / eq) into a 500mL reaction bottle, and slowly heat to React at 155°C for 30 minutes while maintaining stirring. After the reaction is completed, cool to room temperature to obtain a modified bismaleimide prepolymer.

[0045]Add an appropriate amount of acetone to dissolve, stir and mix evenly to obtain a glue solution with a solid content of 62%, impregnate the above glue solution with E glass fiber cloth, and bake in an oven at 160°C for 5 minutes to prepare a prepreg.

[0046] Overlay 8 pieces of the above-mentioned semi-cured sheets with burrs removed, attach 35 micron copper foil up and down, and place them in a vacuum hot press to press to obtain a copper-clad laminate. The specific pressing process is pressing at a pressure of 1.5Mpa and a temperature of 220° C. for 4 hours. The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 2

[0048] Take 30g of 4,4'-diphenyl ether bismaleimide, 70g of 4,4'-diphenylmethane bismaleimide, 50g of diallyl bisphenol A, diallyl bisphenol A di Put 50g of glycidyl ether (epoxy equivalent 220g / eq) into a 500mL reaction flask, heat slowly to 140°C using an oil bath and keep stirring for 50min, cool to room temperature after the reaction is complete, and obtain modified bismaleimide Amine prepolymers.

[0049] Add an appropriate amount of acetone to dissolve, stir and mix evenly to obtain a glue with a solid content of 62%.

[0050] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0051] The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 3

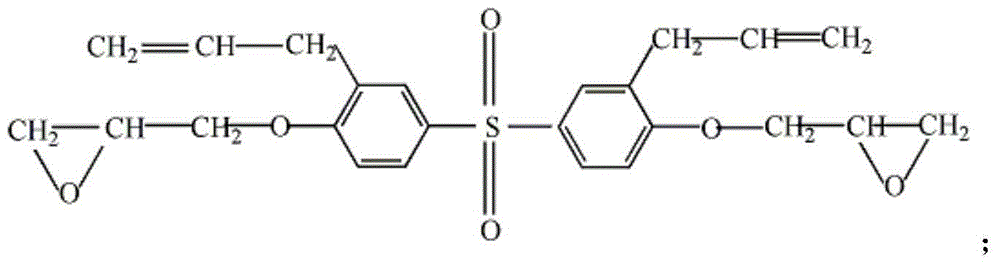

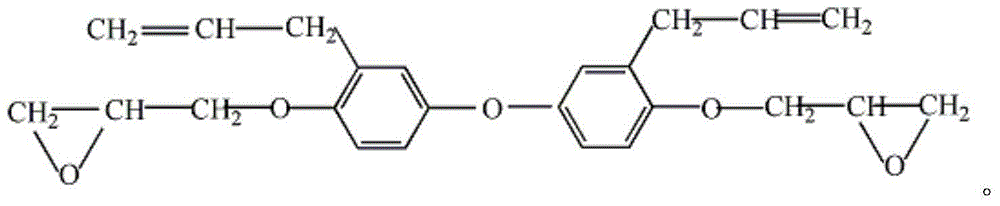

[0053] Take 100g of 4,4'-diphenyl ether bismaleimide, 40g of allyl phenoxy resin, 50g of diallyl bisphenol S diglycidyl ether (epoxy equivalent 215g / eq) into a 500mL reaction bottle , using an oil bath to slowly heat to 140° C. and keep stirring for 60 minutes. After the reaction is completed, cool to room temperature to obtain a modified bismaleimide prepolymer.

[0054] Add an appropriate amount of acetone to dissolve, and after the dissolution is complete, add 23 parts of cyclic phenoxyphosphazene compound (FP-100, Fushimi Pharmaceutical Co., Ltd), stir and mix evenly to obtain a glue with a solid content of 62%.

[0055] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0056] The properties of the obtained copper-clad laminates are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com